Air cushion organic solid refuse tank fermentation system

A technology of organic solids and fermentation system, applied in the direction of solid waste removal, etc., can solve the problems of high equipment investment cost, low land utilization rate, high fermentation cost, etc., and achieve the effect of reasonable cost performance, high land utilization rate and low fermentation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

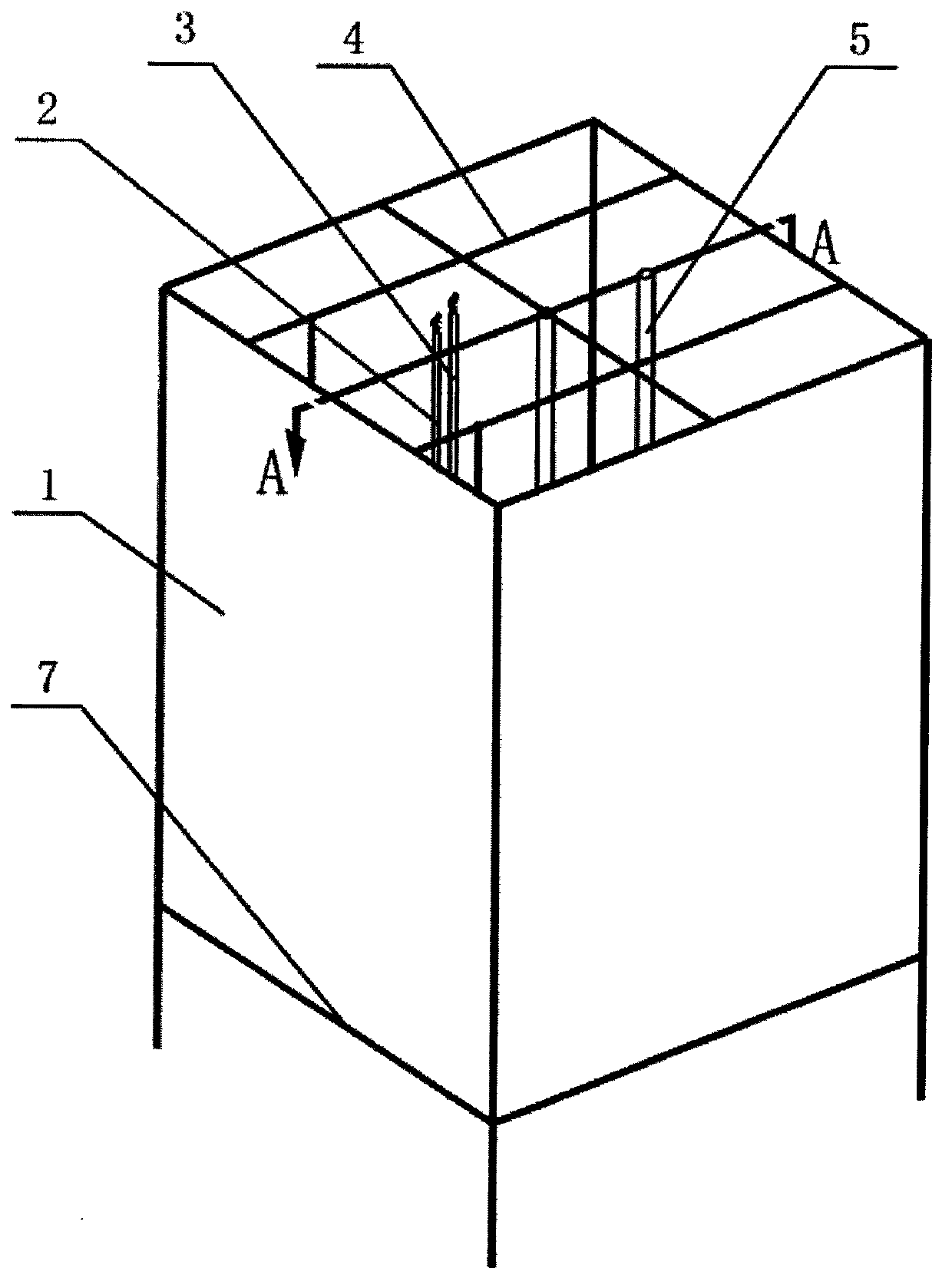

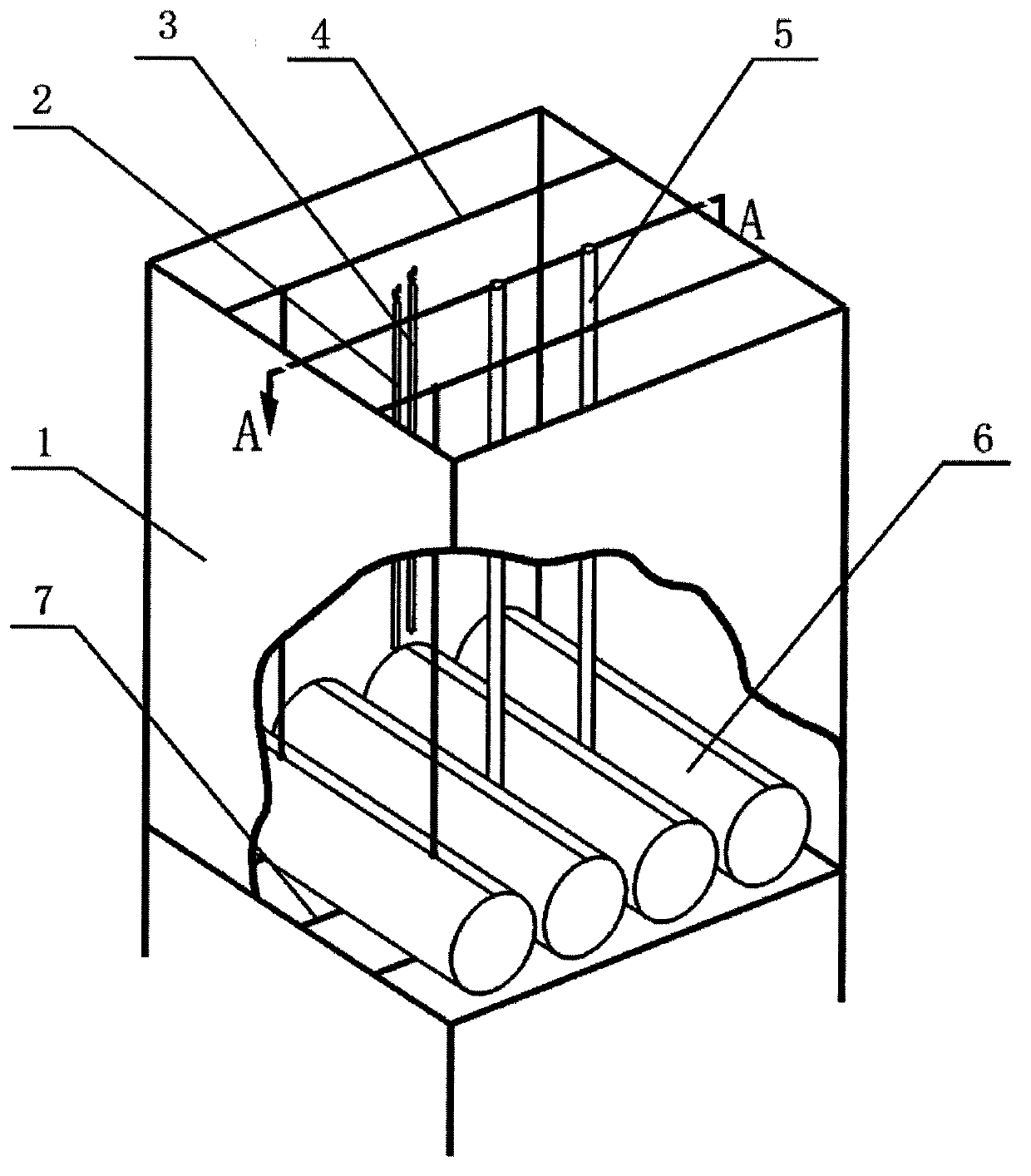

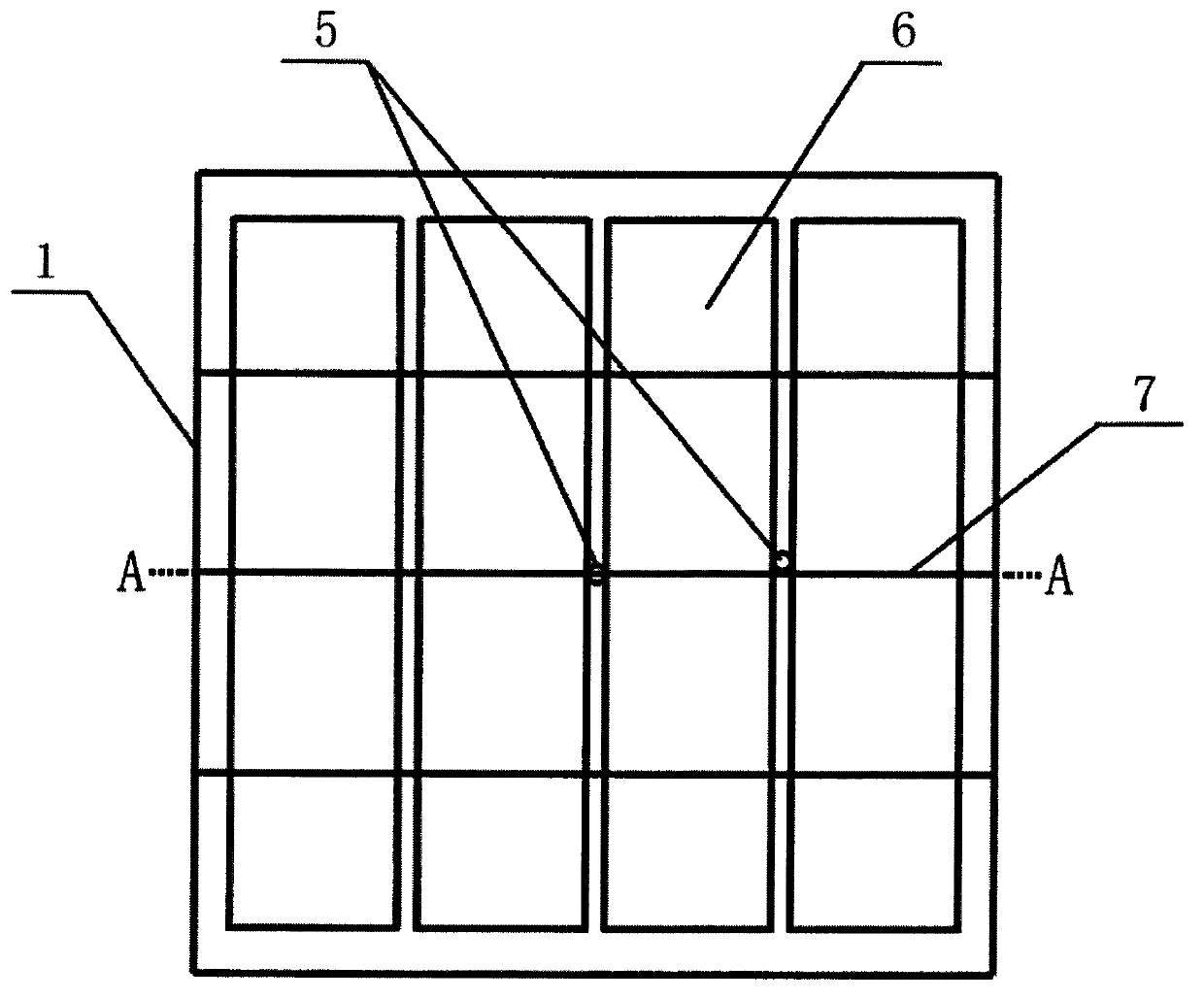

[0058] Such as Figure 1 to Figure 5 As shown, an air cushion type organic solid waste tank fermentation system is composed of at least one fermentation unit, the fermentation unit is a square tank structure, and the fermentation unit includes a fermentation container 1, an aeration device 5, an air cushion 6 and a detection unit. device, a ventilation device 5, an air cushion 6 and a detection device are provided in the fermentation container 1, and it is characterized in that: the top of the fermentation container 1 is provided with a fixing device 4, and the bottom is provided with a support device 7; the ventilation device 5 is located in the fermentation container 1; the air cushion 6 is composed of a plurality of expandable and contractible columnar structures, and each air cushion 6 is connected to each other and fixed on the bottom of the fermentation vessel 1 respectively; the detection device is arranged between the ventilation devices 5 in the fermentation vessel 1. ...

Embodiment 2

[0064] Such as Figure 6 As shown, an air cushion type organic solid waste tank fermentation system differs from Example 1 in that the fermentation vessel 1 is a circular tank structure, wherein the air cushion 6 consists of one or more expandable and contractible rings. With the central axis 8 as the center, it is composed of large to small rings; other structures are the same as in Embodiment 1.

[0065] The working principle of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0067] Such as Figure 7 As shown, an air cushion type organic solid waste tank fermentation system is composed of three fermentation units stacked up and down, and the structure of each fermentation unit is the same as that in Example 1.

[0068] Its working process is as follows:

[0069] When feeding, first use an air compressor to inflate the air cushion 6 and the ventilation device 5 of the upper fermentation unit, because the space between the air cushions 6 is filled after the air cushion 6 is inflated, so that the bottom of the fermentation container is closed. The fermentation material is loaded from the top of the fermentation container 1 of the upper fermentation unit; after the fermentation material is filled and left to stand for a certain period of time, the air in the aeration device 5 is drained, the volume of the aeration device 5 shrinks and becomes smaller, and the material immediately forms a ventilation gap and starts Carry out fermentation; during the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com