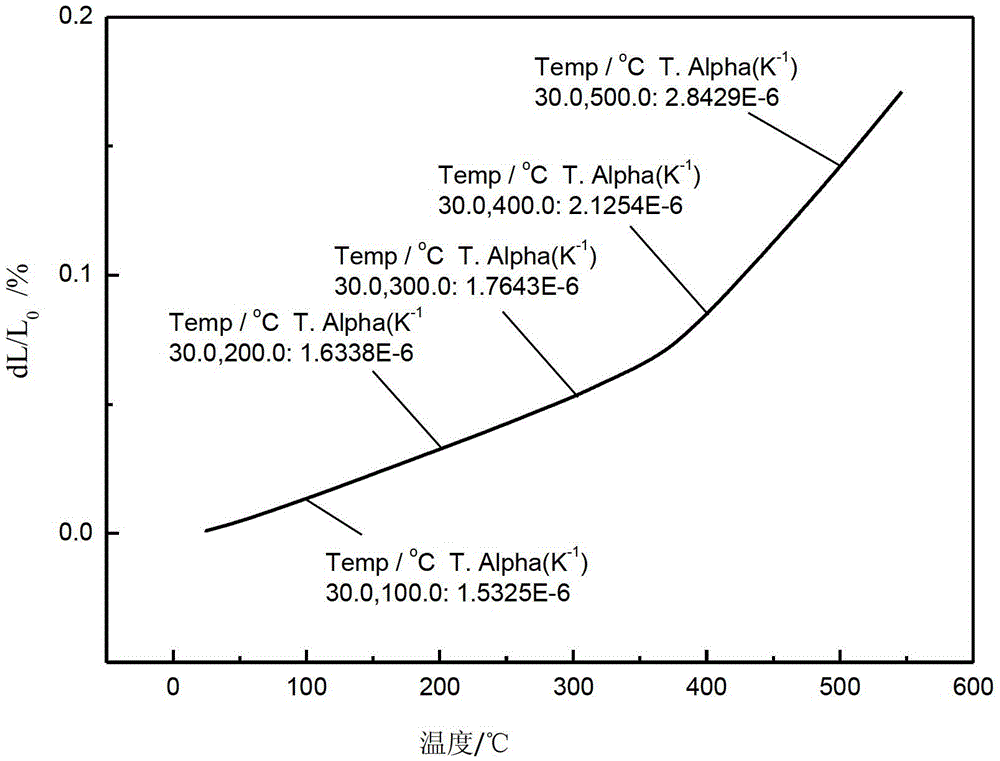

A Welding Material for Alloy Connection with Low Thermal Expansion Coefficient

A low thermal expansion coefficient, welding material technology, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problem of high thermal cracking tendency, and achieve the effect of controlling the hot cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

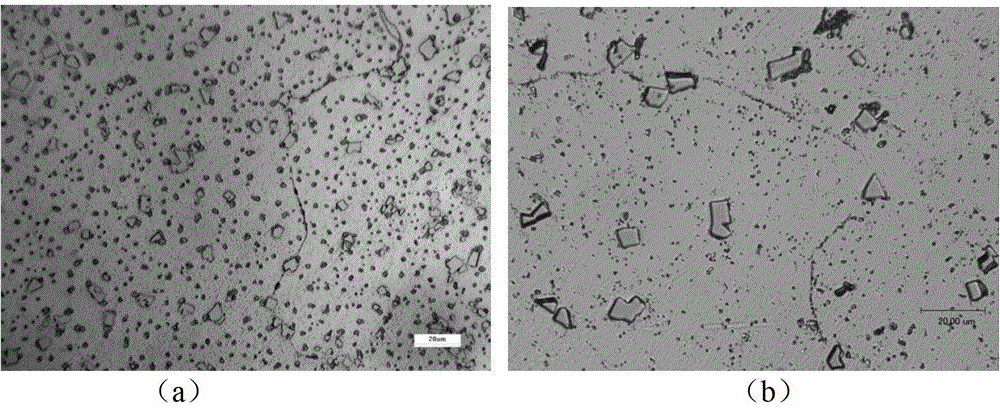

Embodiment 1

[0021] Select Ni, C, Mn, Si, Ti, Co, Sc 2 o 3 Powder mixing, the weight ratio is as follows: Ni: 35.8%; C: 0.1%; Mn: 1.2%; Si: 0.08%; Ti: 1.1%; Co: 0.5%; Sc 2 o 3 : 3.0%; Fe: balance; impurity control: S≤0.01%; P≤0.01%.

[0022] Prepare according to the following production process:

[0023] (1) Dosing, mixing evenly, and compacting according to the above-mentioned component distribution ratio;

[0024] (2) Vacuum melting is carried out by vacuum induction melting. The temperature of vacuum induction melting is 1420°C; the heating time is: the thickness of the cross-section of the sample is 11-20 minutes per centimeter; that is, the thickness of the cross-section is 2cm, and the vacuum induction melting The time is 22 to 40 minutes;

[0025] (3) After the mold shell is poured, it is cooled naturally;

[0026] (4) The ingot is formed into a bar;

[0027] (5) Carry out heat treatment on the bar. The process is as follows: heat the sample to 790°C, keep it warm for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com