Transparency increasing processing method for PC material member surface

A treatment method and surface condensation technology are applied in the field of PC material transparent parts processing technology, which can solve the problems of limited material use, unsightly appearance, blurred transparent decorative parts, etc., to reduce processing costs, increase light transmittance, and aesthetic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

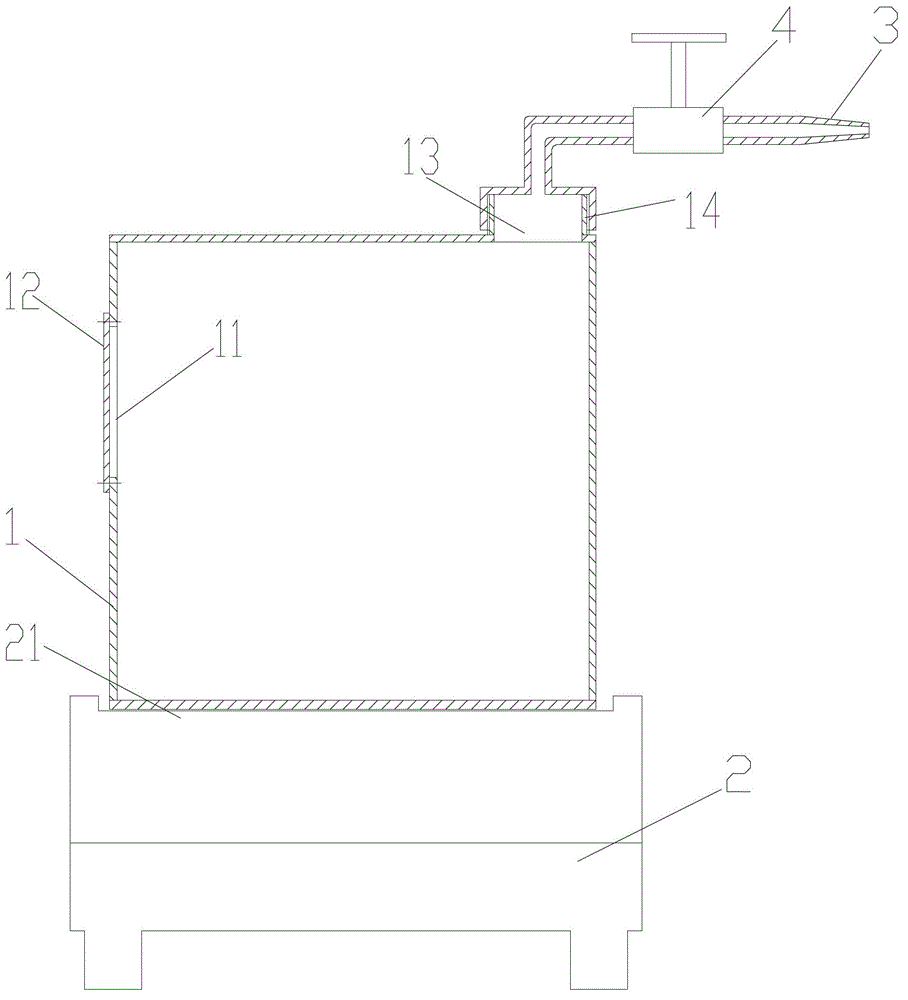

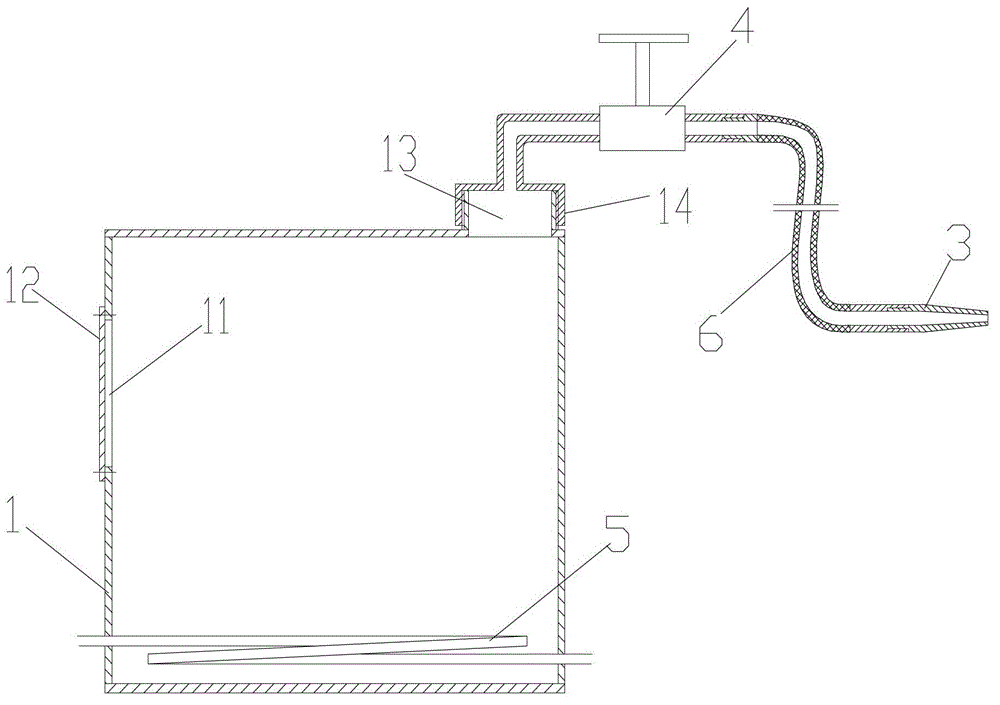

[0022] figure 1 It is a structural representation of the chloroform steam generator of the present invention, figure 2 It is another structural schematic diagram of the chloroform steam generator of the present invention, as shown in the figure: the PC material surface anti-reflection treatment method of the present embodiment comprises the following steps:

[0023] a. At least the PC material parts need anti-reflection surface cleaning treatment;

[0024] b. Heat the chloroform to form chloroform vapor, and at least make the surface of the PC material part to be anti-reflection placed in a chloroform vapor environment for fumigation, and the chloroform will condense on the surface of the PC material part to be anti-reflection and Dissolution; chloroform vapor condenses on the surface of the PC material part to be anti-reflection and dissolves the micro-bulges on the surface of the PC material part to be anti-reflection, and then volatilizes to improve the smoothness and ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com