Organic modified molybdenum disulfide nanosheet layer and preparation method thereof

A technology of molybdenum disulfide and nanosheets, which is applied in the field of molybdenum disulfide nanosheets and nanomaterials, can solve the problems of limiting the development of polymer nanocomposites, the performance of composite materials is not obvious, and the dispersion is poor. Large, low cost, not easy to reunite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

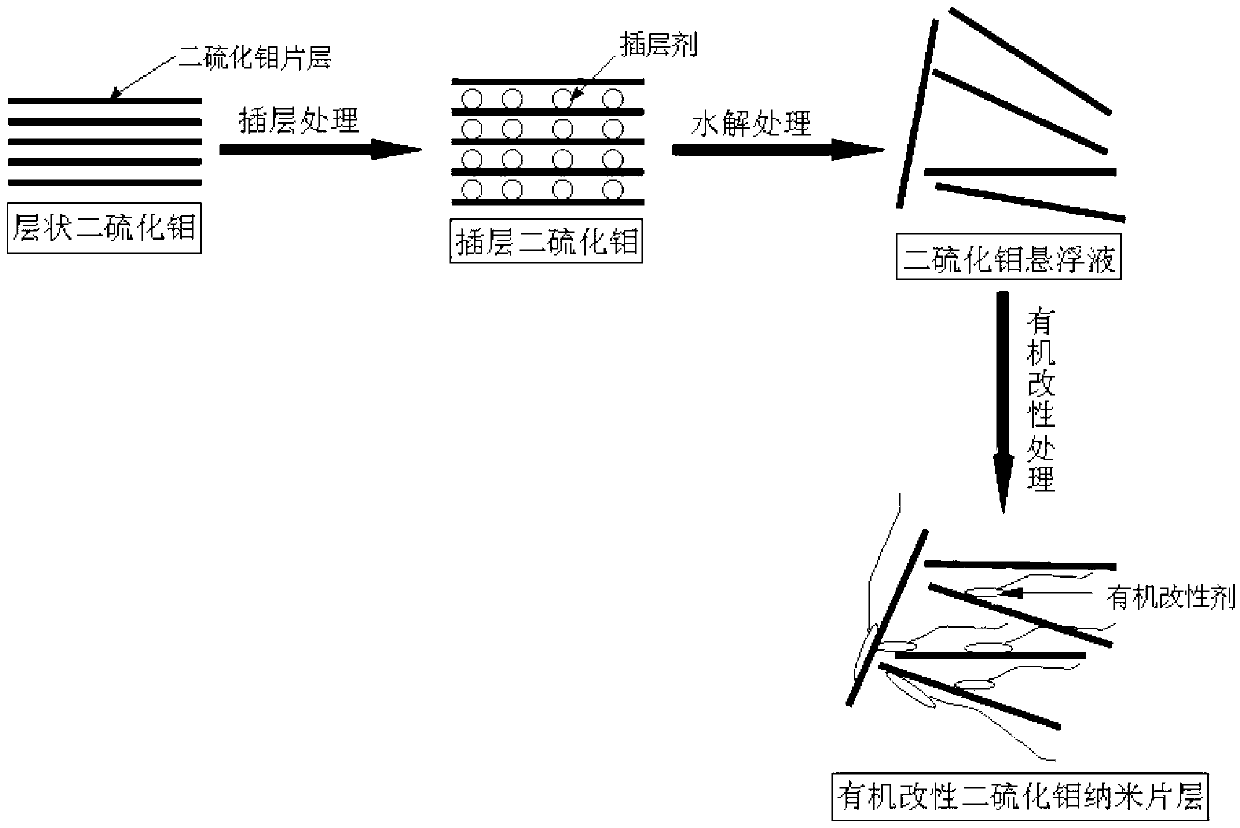

[0035] The invention provides a method for preparing organically modified molybdenum disulfide nanosheets, comprising the following steps:

[0036] Step 1: intercalate the layered molybdenum disulfide with an intercalation agent by a solvothermal method, centrifuge, wash and dry to obtain the intercalated molybdenum disulfide. The present invention has no special limitation on the intercalation treatment process, and methods well-known to those skilled in the art can be used, preferably as follows: adding layered molybdenum disulfide and intercalation agent into an organic solvent, at 25-100°C After reacting for 2-6 hours, the obtained product is centrifuged, washed and dried to obtain intercalated molybdenum disulfide.

[0037] Those skilled in the art can easily know that the ratio of layered molybdenum disulfide and intercalation agent can be selected according to actual conditions, and the type of organic solvent can be selected according to the type of intercalation agent...

Embodiment 1

[0045] (1) Mix 0.003 mol layered molybdenum disulfide with 36 ml 0.5 mol / L n-butyllithium n-hexane solution and put them in a 50 ml reaction kettle, react at 80°C for 4 hours, centrifuge and wash the obtained product and drying to obtain intercalated molybdenum disulfide;

[0046] (2) Add 0.1 g of intercalated molybdenum disulfide to 100 ml of deionized water for ultrasonic hydrolysis to obtain molybdenum disulfide suspension;

[0047] (3) Add 0.5 g of cetyltrimethylammonium bromide to the molybdenum disulfide suspension obtained in step (2), react at 80°C for 8 hours, centrifuge, wash and dry the obtained product to obtain Organically modified molybdenum disulfide nanosheets T1.

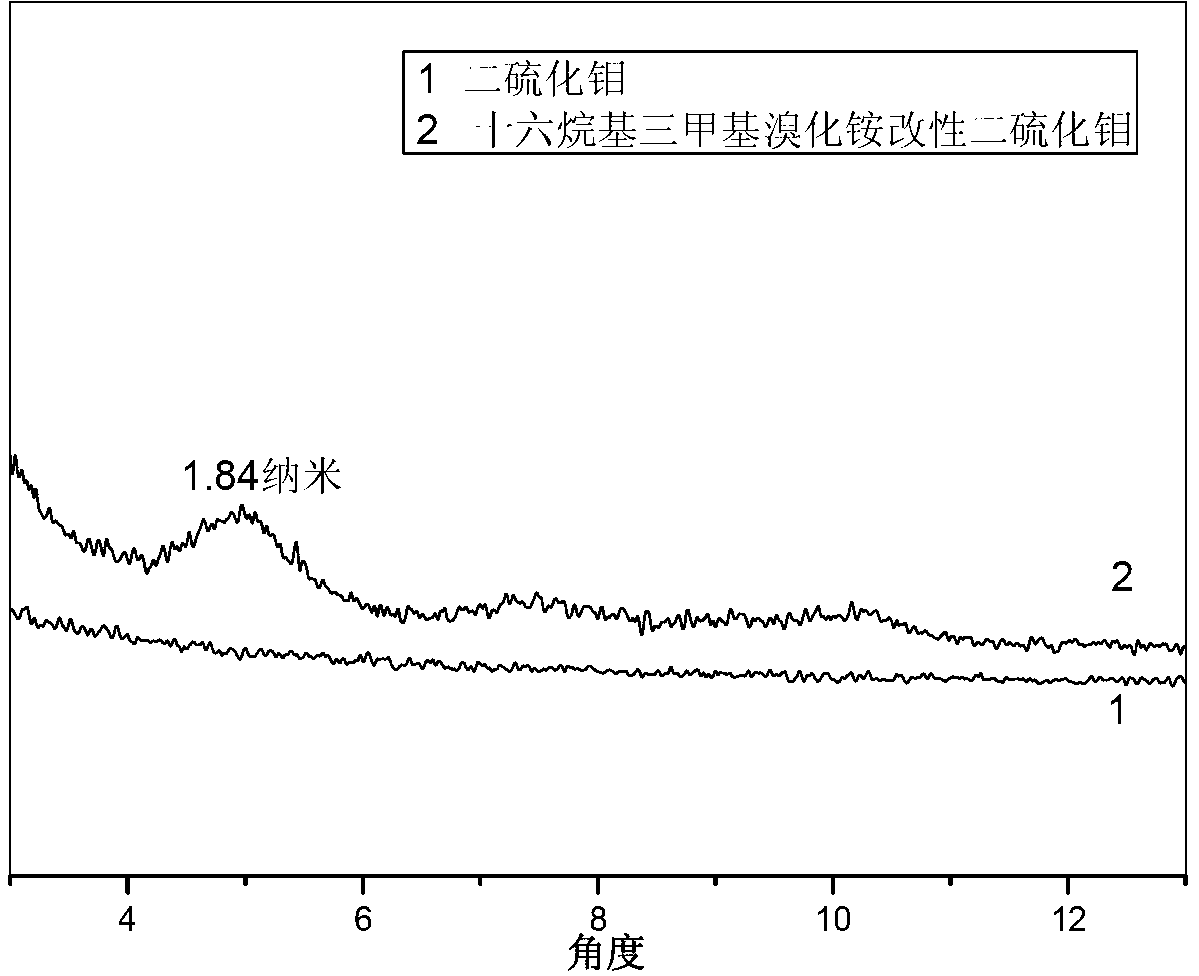

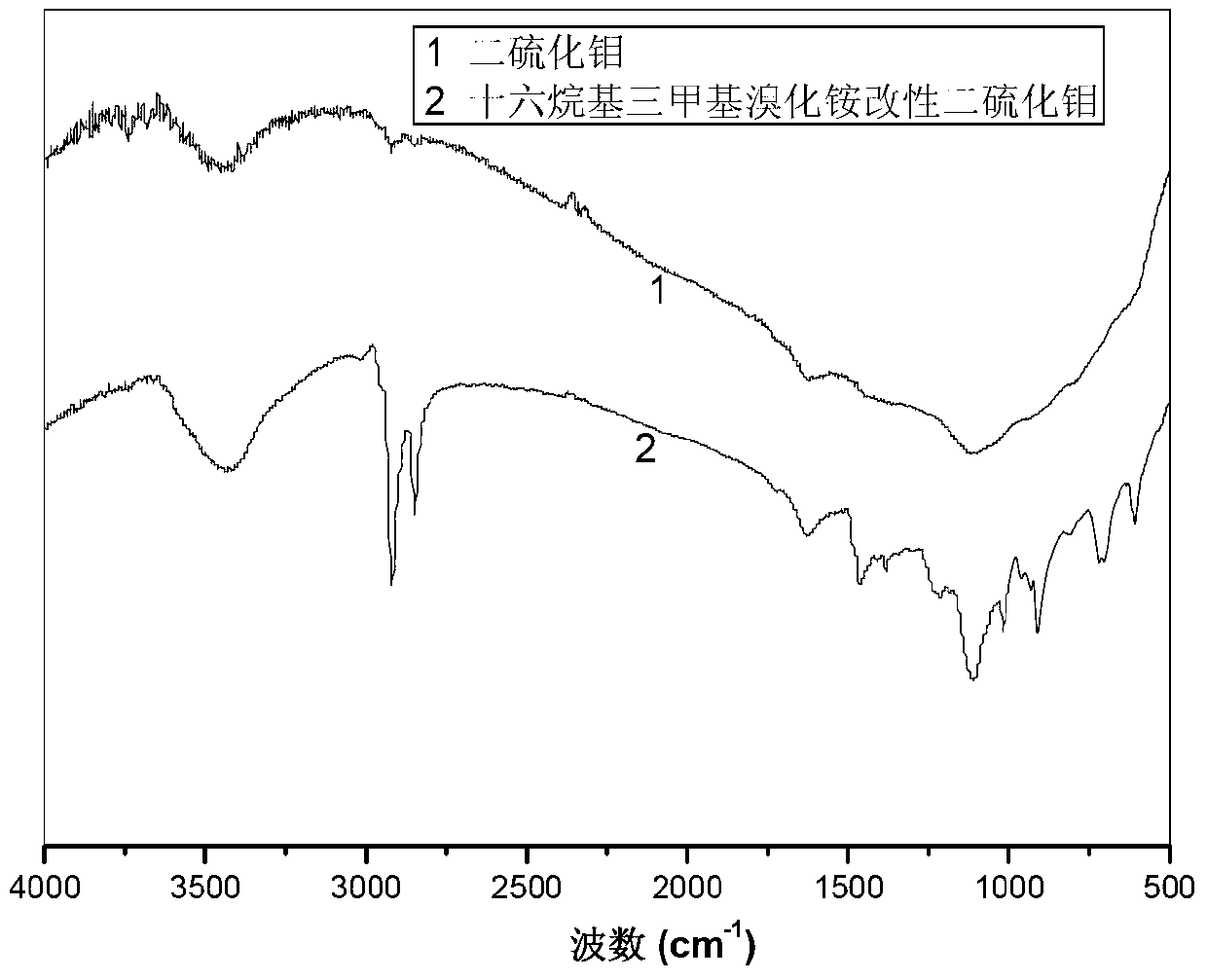

[0048] Such as figure 2 As shown, the X-ray diffraction test results of T1 show that the interlayer spacing increases from 0.62 nanometers of the raw material molybdenum disulfide to 1.84 nanometers, and the interlayer spacing increases significantly. Such as image 3 As shown, the results of F...

Embodiment 2

[0050] (1) Mix 0.006 moles of layered molybdenum disulfide with 36 milliliters of 0.5 moles / liter n-butyllithium n-hexane solution, put them in a 50 milliliter reaction kettle, react at 80°C for 6 hours, centrifuge and wash the obtained product and drying to obtain intercalated molybdenum disulfide;

[0051] (2) Same as step (2) of embodiment 1;

[0052] (3) Add 0.6 g of sodium dodecylsulfonate to the molybdenum disulfide suspension obtained in step (2), react at 60°C for 6 hours, centrifuge, wash and dry the obtained product to obtain organically modified Molybdenum disulfide nanosheets T2.

[0053] Such as Figure 4 As shown, the X-ray diffraction test results of T2 show that the interlayer spacing increases from 0.62 nanometers of the raw material molybdenum disulfide to 1.57 nanometers, and the interlayer spacing increases significantly. Such as Figure 5 As shown, the results of Fourier transform infrared spectroscopy of T2 show that T2 has obvious sulfate and carbon-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com