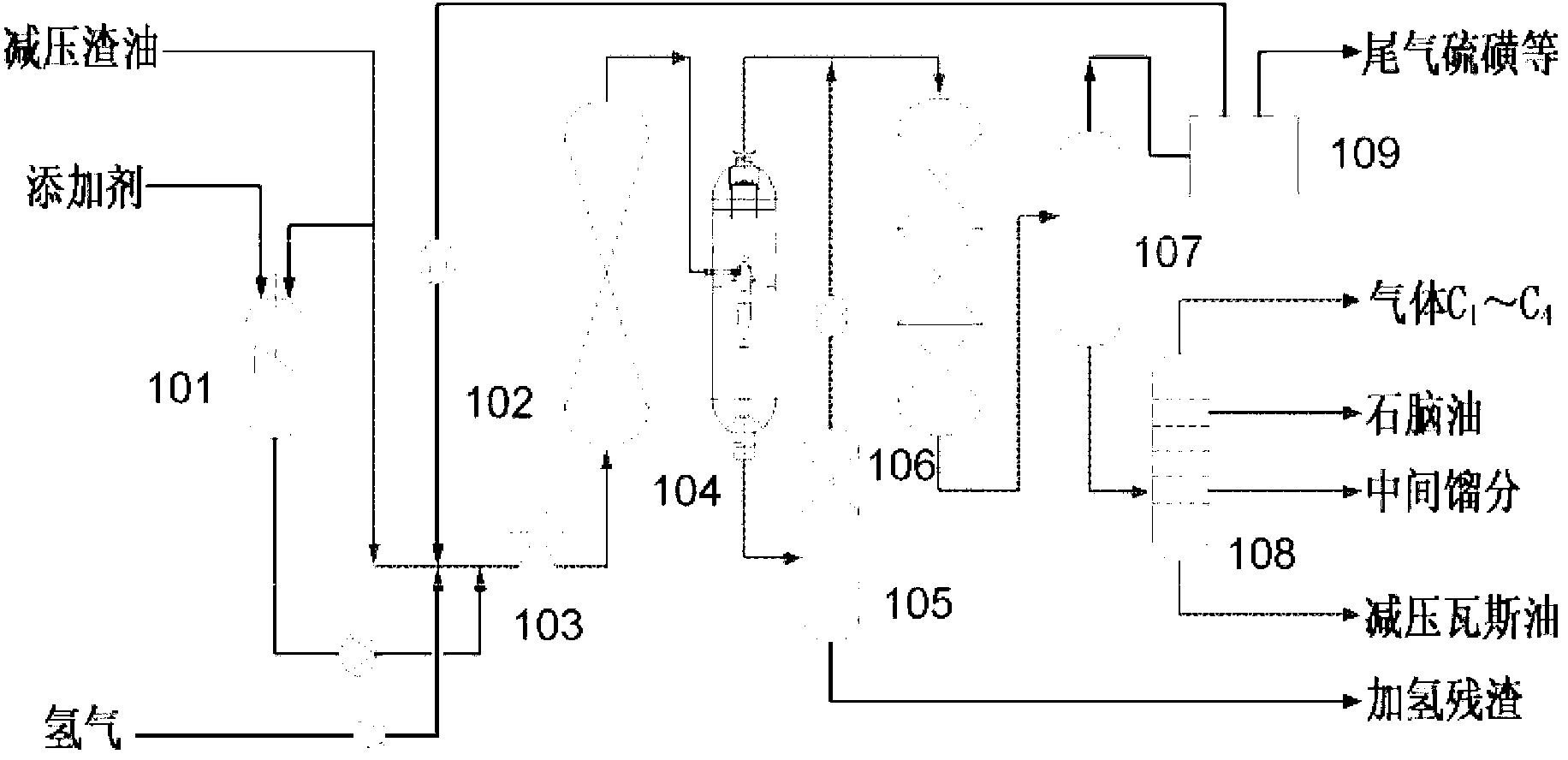

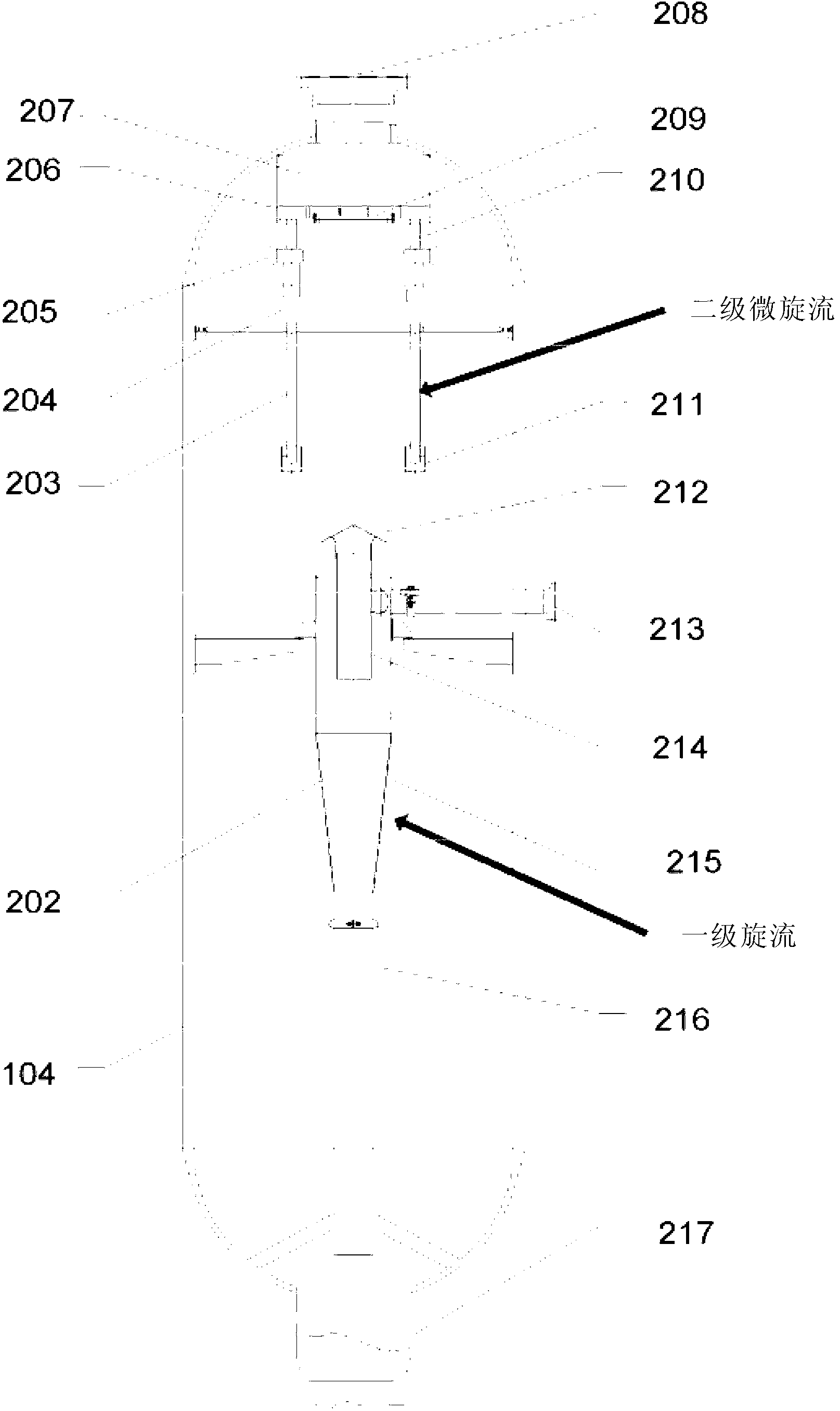

Two stage cyclone series connection strengthening separation method for reaction product in suspension bed hydrogenation process, and apparatus

A reaction product and enhanced separation technology, which is applied in the fields of hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of unfavorable continuous production, large volume, long separation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In a 1 million tons / year residual oil hydrotreating process, according to the method of the present invention, the high temperature and high pressure separator of the cyclone enhanced separation method is used to treat the high pressure multiphase mixture containing solid catalyst, liquid particles and gas Two-stage series cyclone enhanced separation is carried out to achieve the purpose of effectively separating liquid particles and gases in high-pressure multi-phase mixtures with extremely low pressure drop. The specific operation process and effect are described as follows:

[0055] 1. Material properties and related parameters

[0056] The high-pressure multi-phase mixture is circulating hydrogen gas with liquid droplets and solid catalysts in it, wherein circulating hydrogen is the continuous phase medium, and oil, liquid droplets and solid catalysts are the dispersed phase medium. The processing capacity of circulating hydrogen gas is 38910kg / h, and the gas phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com