High-hardness high-tenacity cold and hot work die steel and production method thereof

A production method and technology of die steel, applied in the field of die steel, can solve the problems of insufficient strength, insufficient toughness, low hardness and strength, etc., and achieve the effects of improved service life, strong comprehensive performance, and not easy to crack and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

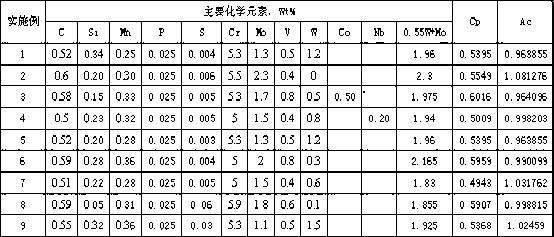

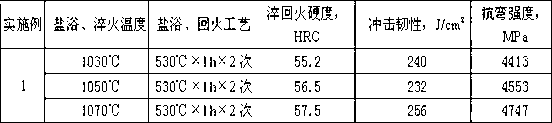

[0032] Below in conjunction with specific embodiment the present invention is described in further detail:

[0033]

[0034] The raw materials for steel smelting in the example are: mold steel return material, industrial pure iron, ferrotungsten, ferromolybdenum, ferrochrome, ferrovanadium, etc., after intermediate frequency + electroslag remelting → steel ingot → heating and homogenization of steel ingot → fast forging and precision forging Machine deformation → square billet → rolling finished product or forging into forging finished product;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com