A kind of low chloride radical rare earth carbonate processing method

A rare earth carbonate and processing method technology, applied in the direction of rare earth metal compounds, chemical instruments and methods, crystal growth, etc., can solve the problem of high chloride content, achieve less residual chloride ions, shorten processing time, and reduce chloride Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the essence of the present invention, the specific embodiments of the present invention are described as follows in conjunction with the accompanying drawings.

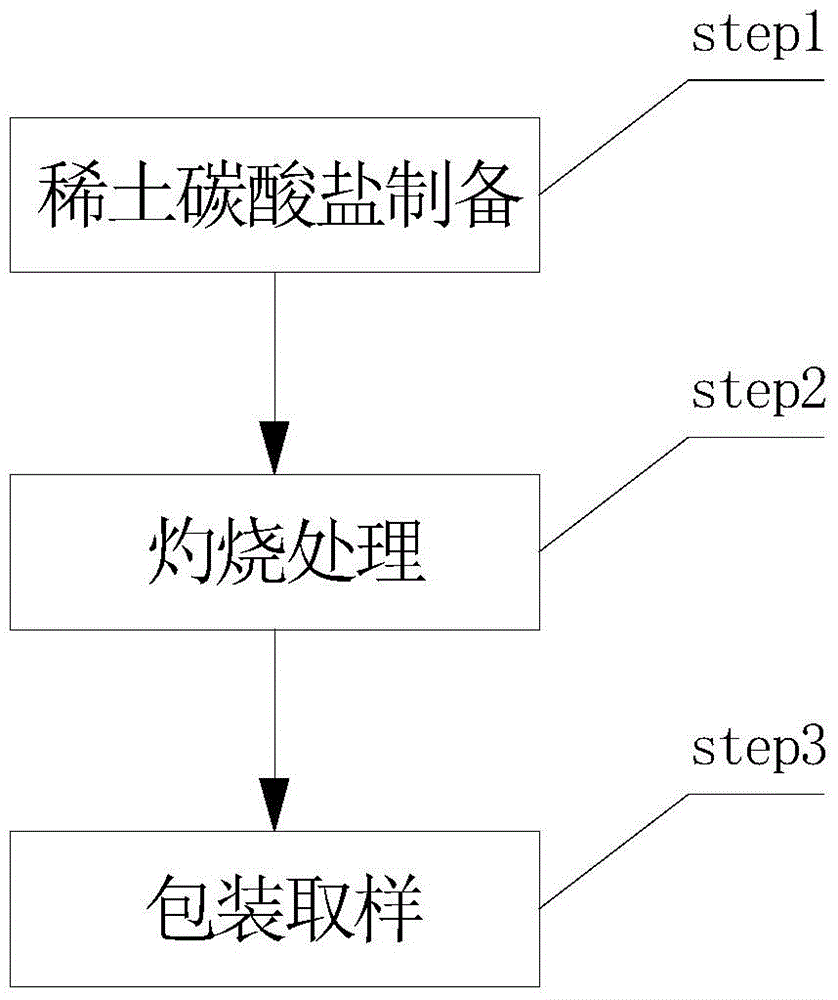

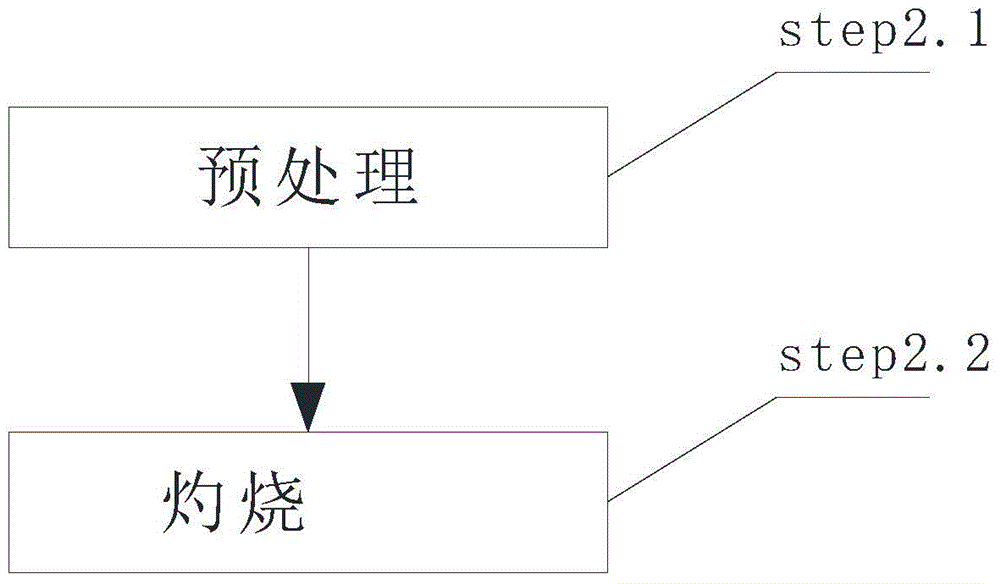

[0033] Such as figure 1 As shown, a low-chloride rare earth carbonate processing method includes: the first step step1 rare earth carbonate preparation, used to extract the rare earth carbonate from the rare earth chloride solution; the second step step2 burning treatment, the The rare earth carbonate is added to the material bowl, and the material bowl is put into the tunnel kiln for burning to further remove the chloride radicals in the rare earth carbonate; the third step step3 is packaging and sampling, and the burned material bowl is Take it out from the tunnel kiln, cool it down, remove the material bowl, pack and sample the prepared rare earth product.

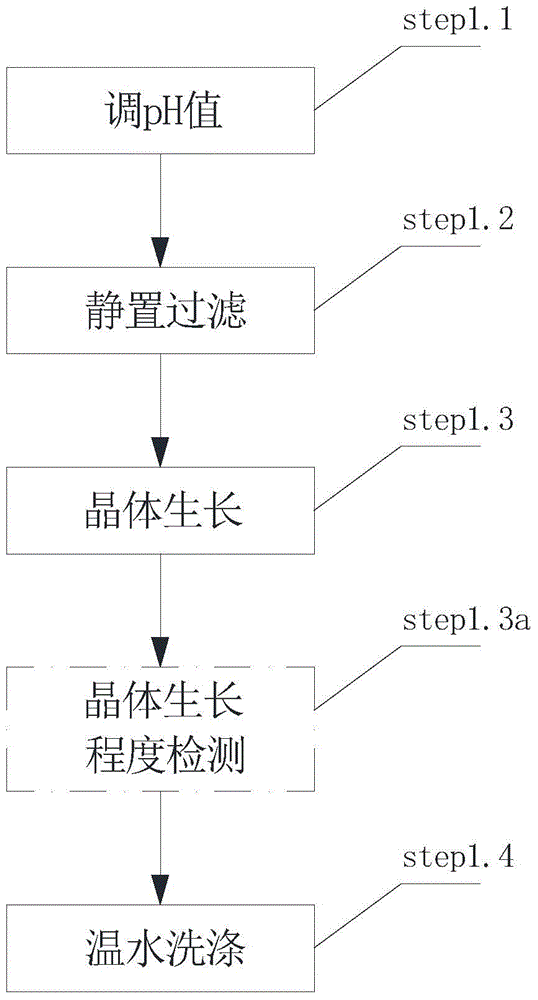

[0034] Among them, such as figure 2 As shown, the first step step1 rare earth carbonate preparation step is subdivided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com