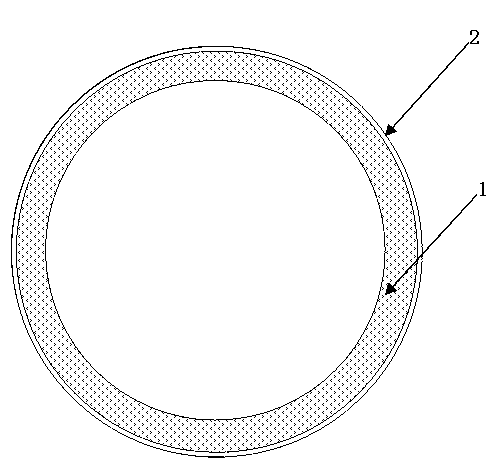

Double-layer PE gas pipe with termite-proof protective layer

A protective layer and anti-termite technology, applied in the direction of pipeline protection, pipes, rigid pipes, etc., can solve the problems of troublesome process, gas leakage, bitten through, etc., achieve the effect of safe and convenient connection, and improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw material of outer protective layer 2 is 100 parts of PP-H resin, 2 parts of sorbitol nucleating agent, 2 parts of yellow masterbatch, 3 parts of titanium dioxide; the raw material of inner layer 1 is 100 parts of PE100 resin, 3 parts of black masterbatch, The two groups of raw materials were blended separately and entered into a double-layer co-extrusion die to extrude the pipe to prepare a double-layer PE gas pipe with a nominal outer diameter of 20mm and an outer layer thickness of 0.2mm. Before the pipe is connected by electrofusion, use a special tool to cut the outer protective layer along the edge of the connection part, then peel off the protective layer to expose the PE resin connection part of the electrofusion connection, and insert it into the electrofusion pipe fitting for electrofusion connection.

Embodiment 2

[0032] The raw material of outer protective layer 2 is 100 parts of PP-R resin, 2 parts of sorbitol acetal nucleating agent, and 2 parts of black masterbatch; the raw material of inner layer 1 is 100 parts of PE100-RC resin, 5 parts of black masterbatch, two The raw materials of the group were blended separately and entered into a double-layer co-extrusion die to extrude the pipe to prepare a double-layer PE gas pipe with a nominal outer diameter of 225mm and an outer layer thickness of 2.5mm. Connection method is the same as embodiment 1.

Embodiment 3

[0034] The raw material of the outer protective layer 2 is 100 parts of PP-R resin, 2 parts of orange masterbatch, and 3 parts of titanium dioxide; the raw material of the inner layer 1 is 100 parts of PE100 resin and 3 parts of black masterbatch. The pipe is extruded from a layer co-extrusion die to prepare a double-layer PE gas pipe with a nominal outer diameter of 110 mm and an outer layer thickness of 0.7 mm. Connection method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com