Casing integrating type capacitance touch screen

A capacitive touch screen, integrated technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem of fragile touch screen, fragile cover plate, poor dustproof and waterproof performance and other issues, to achieve the effect of reducing raw material and processing costs, reducing production and processing costs, and improving shock resistance and drop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

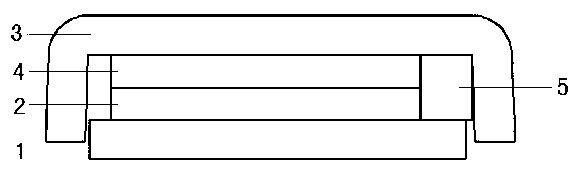

Embodiment 1

[0030] see figure 2 The structure schematic diagram of the first embodiment of the case-integrated capacitive touch screen provided by the present invention includes a display screen 1, an ITO sensor 2, a housing 3, an optical glue 4, and a flexible circuit board 5; the display screen 1 is used for displaying images The display screen, preferably an LCD display screen, has fast response speed, good contrast ratio, high brightness, large viewing angle and rich colors; the ITO sensor 2 is arranged on the display screen 1 for sensing the nano-indium tin of the touch point metal oxide; the casing 3 includes a casing and a cover plate, and the casing and the cover plate are injection-molded into an integral structure for protecting the ITO sensor 2; at the same time, the existing tempered glass-based The method of making the protective cover of the material and the casing separately is simple, reduces the cost of raw materials and processing, and has certain advantages in reducing...

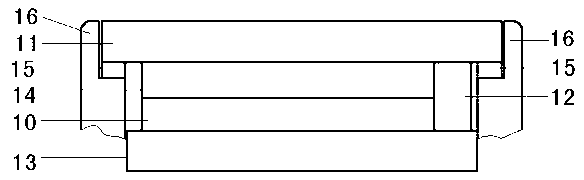

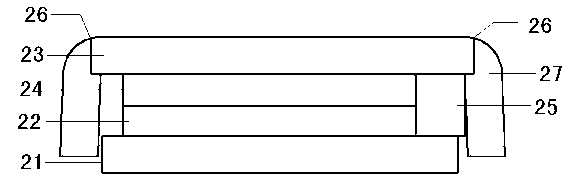

Embodiment 2

[0032] see image 3 The structural schematic diagram of the second embodiment of the case-integrated capacitive touch screen provided by the present invention, including a display screen 21, an ITO sensor 22, a cover plate 23, an optical glue 24, a flexible circuit board 25, a welding port 26, and a case 27 The display screen 21 is used to display the display screen of the image, preferably an LCD display screen, which has fast response speed, good contrast ratio, high brightness, large viewing angle and rich colors; The nano-indium tin metal oxide of the touch point is measured; the cover plate 23 is arranged on the top of the ITO sensor 22, which is a plastic cover plate or a transparent glass cover plate, which improves the shockproof and drop-resistant ability of the product and plays a good role in protection. The effect of ITO sensor; Optical adhesive 24 is used for bonding cover plate 23 and ITO sensor 22; As the detailed description to optical adhesive, described optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com