Production method of black garlic

A production method and a technology for black garlic are applied in the field of food processing to achieve the effects of sweet and sour taste, promotion of total phenol content and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

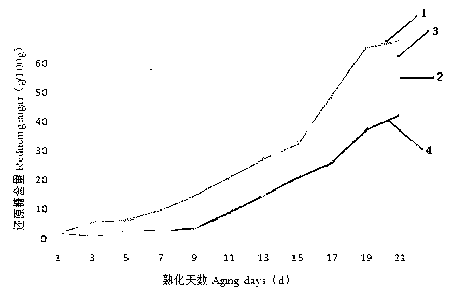

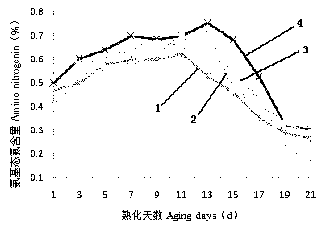

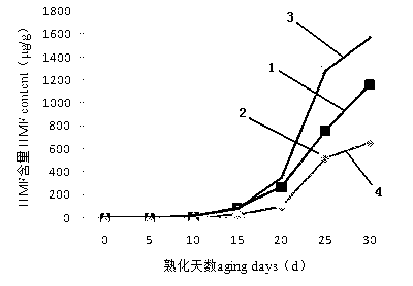

[0031] The fresh garlic is subjected to different pretreatments, and then aged at a temperature of 60-90°C and a humidity of 60-80%. With the increase of the aging days, the reducing sugar content, amino nitrogen content, HMF content, browning Degree and total phenol content are shown in the attached figure 1 , 2 , 3, 4, 5.

[0032] The different preprocessing operations are:

[0033] ① Low-temperature freezing pretreatment: freeze the garlic at -18°C for 24 hours;

[0034] ②Ultrasonic pretreatment: ultrasonically treat the garlic for 4 hours at 100Hz;

[0035] ③Respiratory depression pretreatment: put the garlic in a sealed bag, vacuumize and seal until the absolute vacuum is 0-1000Pa;

[0036] ④ Pretreatment method of the control group: the control group did not have any pretreatment, and was directly bagged and sealed.

[0037] From figure 1 It can be seen from the results that low-temperature freezing pretreatment, ultrasonic pretreatment, and respiratory depressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com