Numerical control conical crushing machine

A technology of cone crushers and crushers, which is applied in the direction of grain processing, etc., and can solve problems such as the inability to adjust the spacing by numerical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

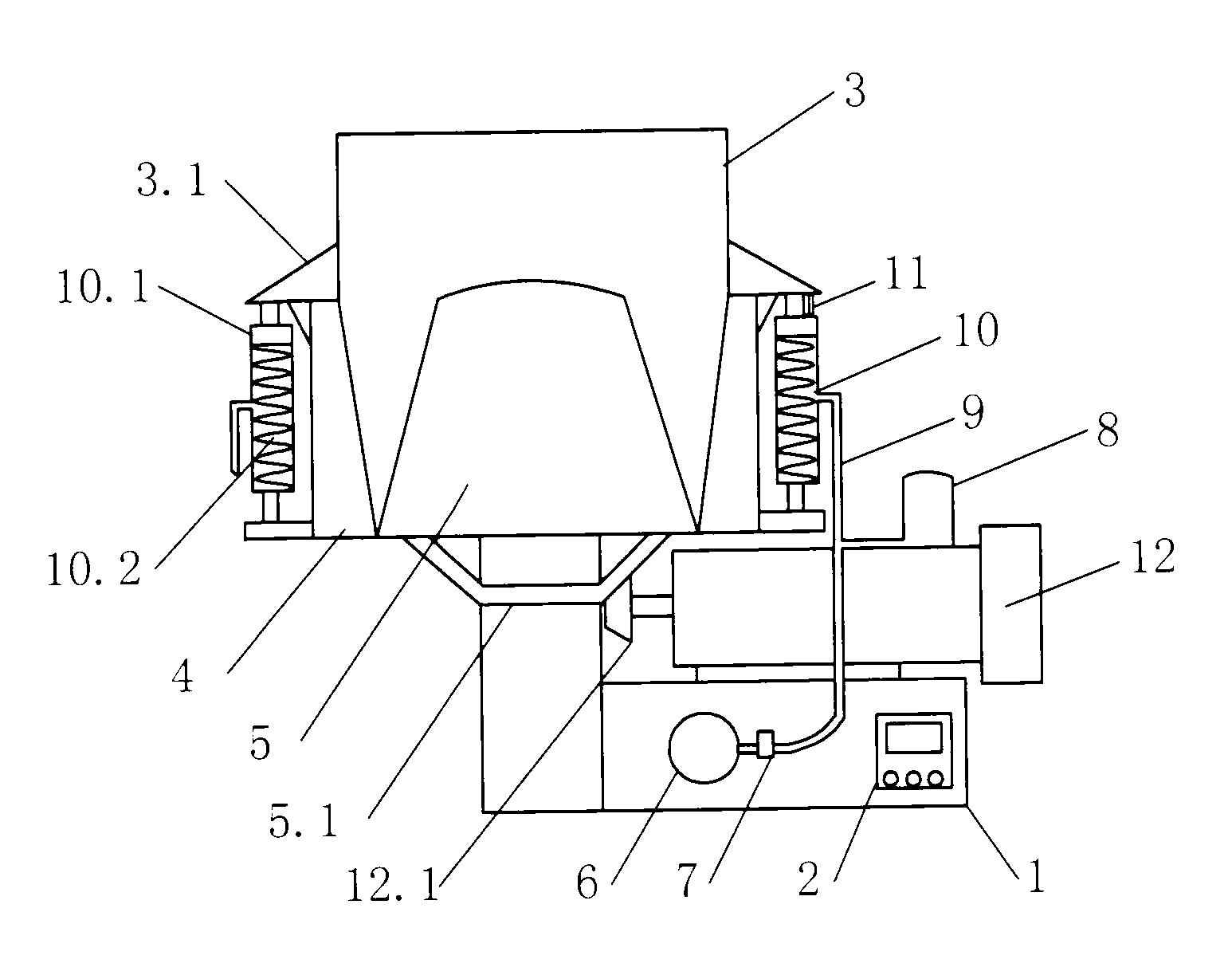

[0020] As shown in the figure, a crusher 3 is installed on the frame 1, a moving cone 5 is installed in the crusher through a bearing, a fixed cone 4 is sleeved outside the moving cone, and the fixed cone is supported by the hydraulic expansion device 10 on the pallet 3.1 and between the backplanes on the rack;

[0021] An air motor 12 is installed on one side of the frame, and the motor gear 12.1 of the air motor is installed in mesh with the moving bevel gear 5.1 on the moving cone.

[0022] A hydraulic pump 6 is installed at the lower part of the frame, and the hydraulic pump is connected with the solenoid valve 7 , the buffer 8 and the hydraulic expansion device 10 through the hydraulic oil pipe 9 .

[0023] A piston 10.1 and a spring 10.2 are installed in the hydraulic retractor.

[0024] A distance sensor 11 is installed between the support plate and the piston rod.

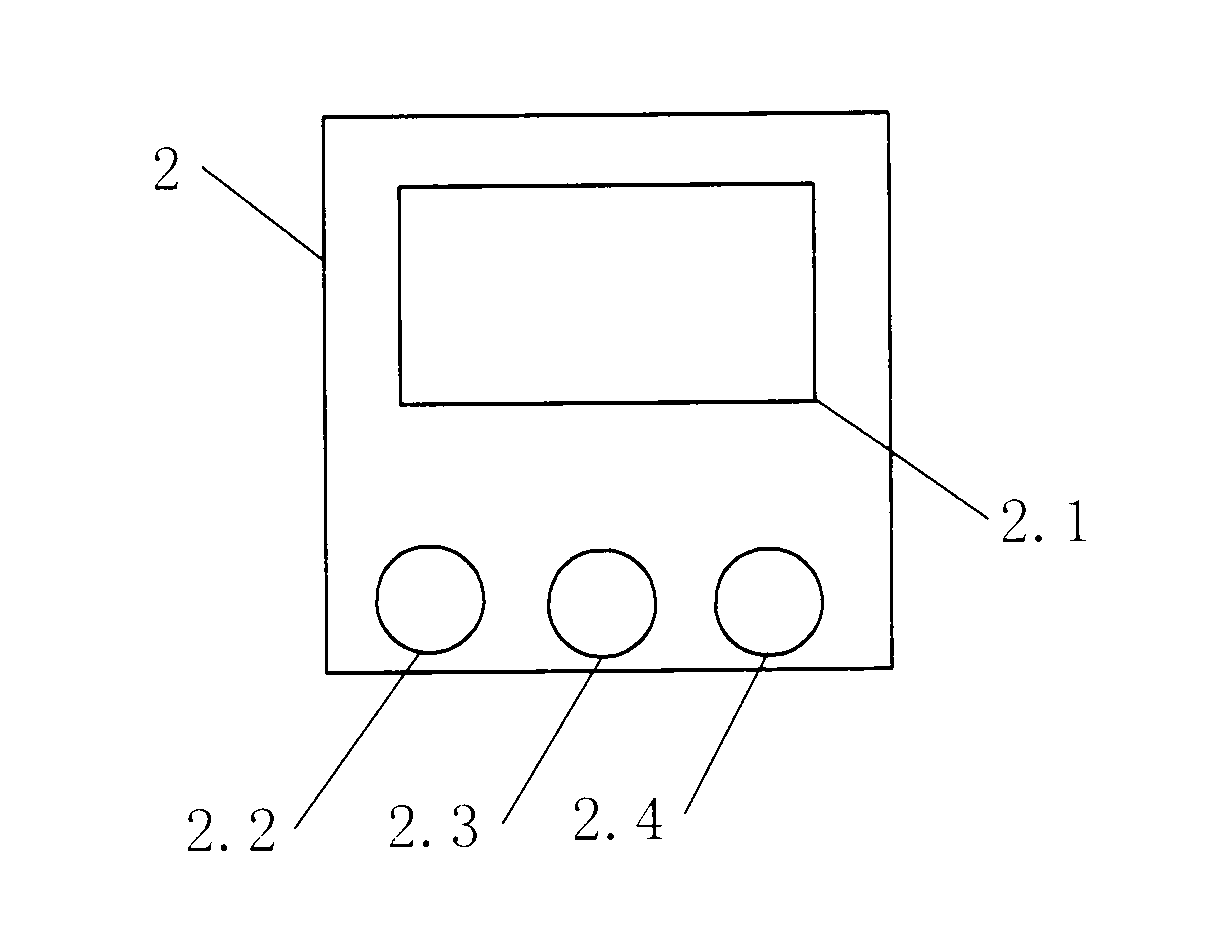

[0025] A numerical control controller 2 is arranged on the frame, and a data input display 2.1, a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com