Efficient energy-saving and noise-reducing servo spot-welding equipment

A high-efficiency, energy-saving, spot-welding equipment technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of low welding accuracy, low welding efficiency, and difficult to control accuracy, and reduce one welding point. , the effect of fast running speed and slight noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

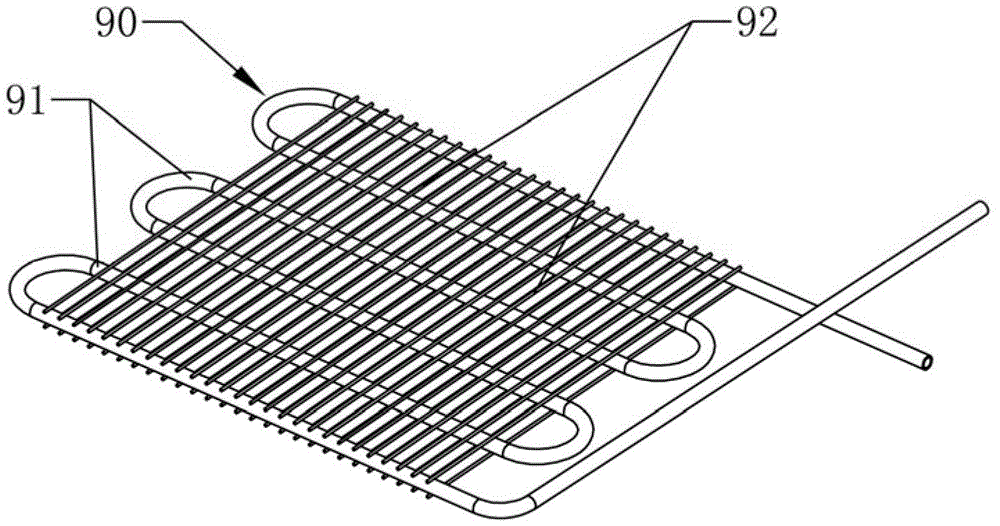

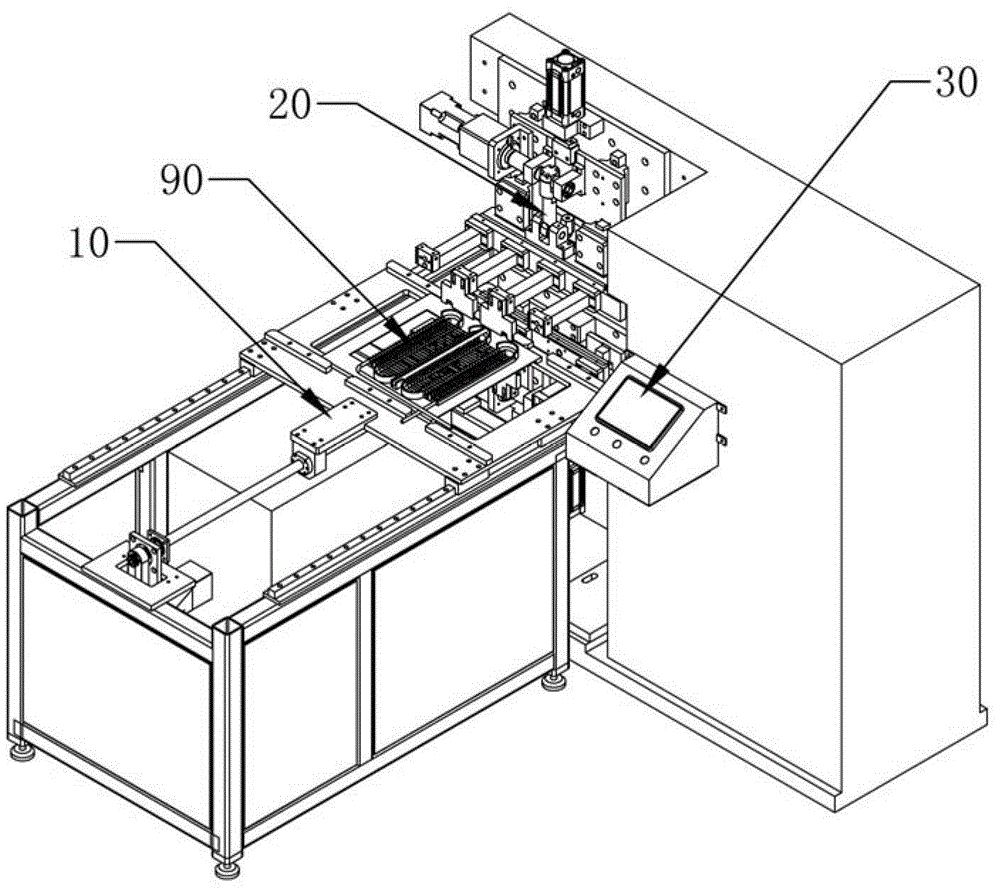

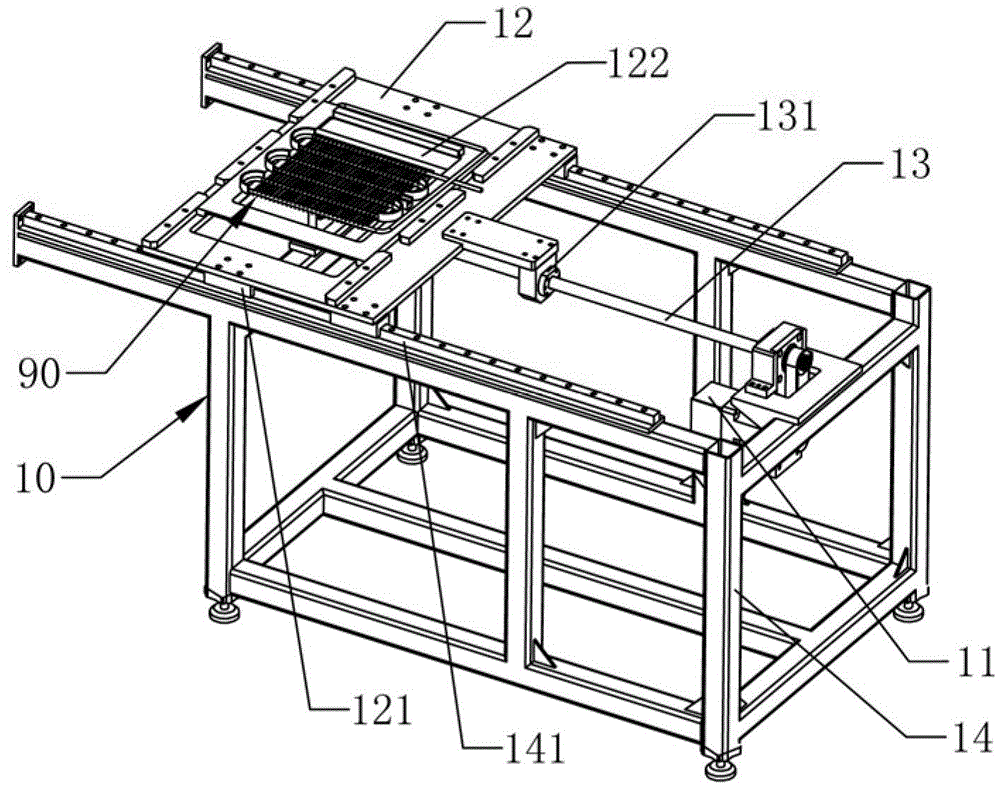

[0027] Such as Figure 1 to Figure 5 As shown, a high-efficiency energy-saving noise reduction servo spot welding equipment includes a welding head lifting mechanism 20, an automatic feeding device 10 and a control module 30, and the welding head lifting mechanism 20 is arranged at the feeding output end of the automatic feeding device 10; The welding head elevating mechanism 20 includes a base 25, a servo reducer 22 and a welding head 23. The servo reducer 22 is arranged on the base 25 and can drive the welding head 23 to perform linear reciprocating motion. The servo reducer 22 passes through the crank The connecting rod mechanism is connected with the welding head 23; the crank connecting rod mechanism includes a crank 221 and a connecting rod 222, the crank 221 is connected with the rotating shaft of the servo reducer 22, and the two ends of the connecting rod 222 are connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com