Automatic grinding device for spherical pair

A grinding device and technology of spherical pair, which is applied in the field of grinding machine, can solve the problems of insufficient contact of the mating surface of the spherical pair, uneven grinding of the mating surface, and difficult formation of oil film, etc., to achieve flexible and adjustable clamping height, remarkable practicability and Effects of improving economy and grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

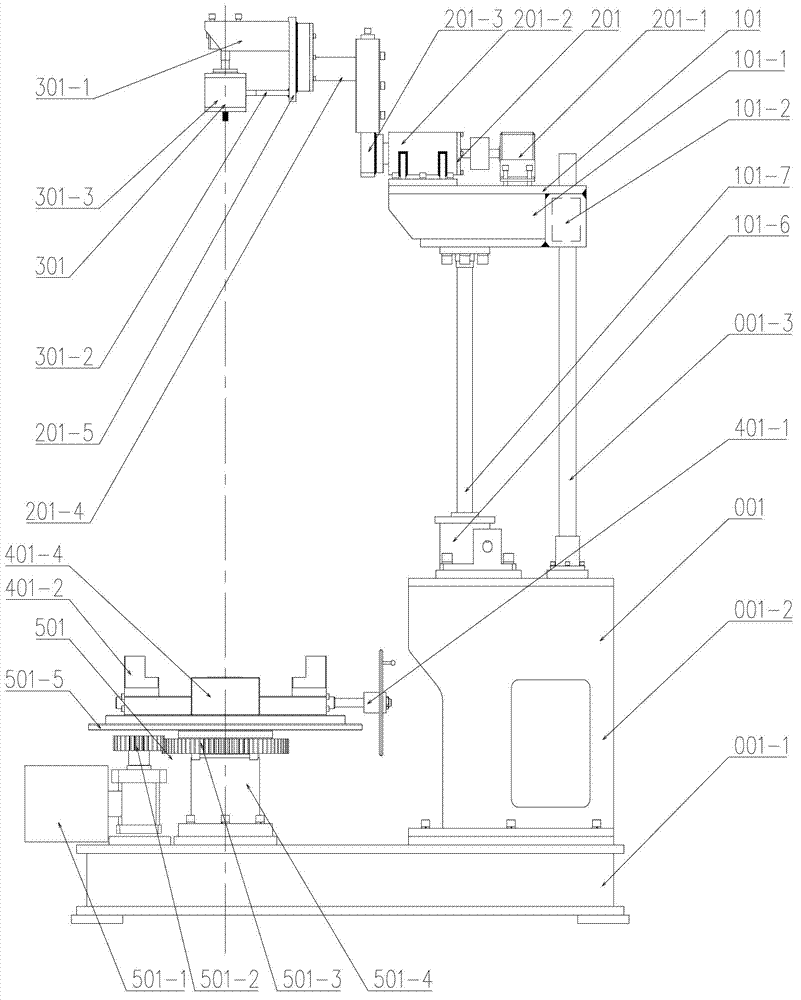

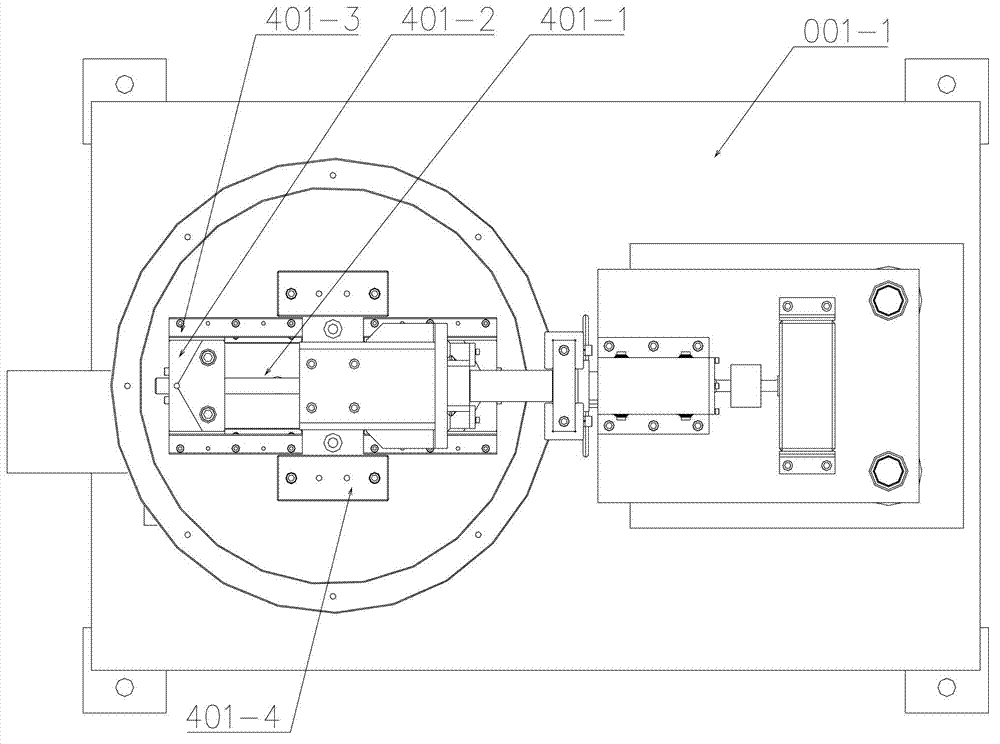

[0022] In order to make the content of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-Figure 2 and specific implementation methods for further description.

[0023] figure 1 It is a schematic diagram of the structure of the spherical pair automatic grinding device, figure 2 yes figure 1 top view, such as figure 1 , figure 2 As shown, the spherical pair automatic grinding device of the present invention includes a frame assembly 001 , a carriage assembly 101 , an upper transmission assembly 201 , a lifting assembly 301 , a clamping assembly 401 and a lower transmission assembly 501 .

[0024] The frame assembly 001 includes a base 001-1, a support base 001-2 and a guide rod 001-3.

[0025] The carriage assembly 101 includes a carriage 101-1, a linear bearing 101-2, a lead screw lifter 101-6 and a lead screw 101-7.

[0026] The upper transmission assembly 201 includes a swing motor 201-1, a swing rod 201-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com