Powder conveyor

A powder conveying and conveying trough technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as low production efficiency, large dust, and failure to meet actual requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

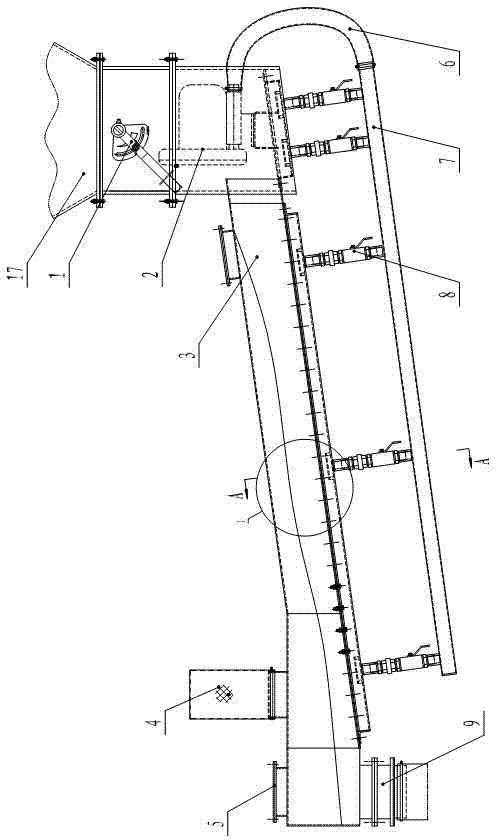

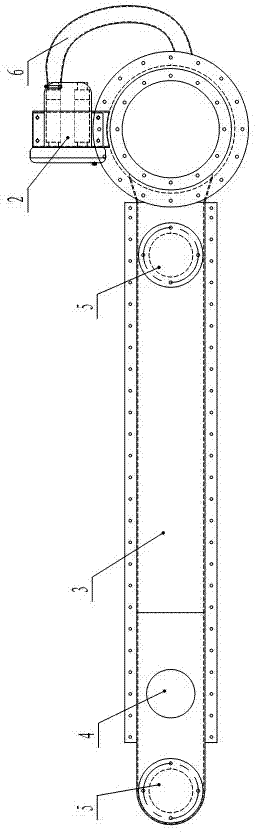

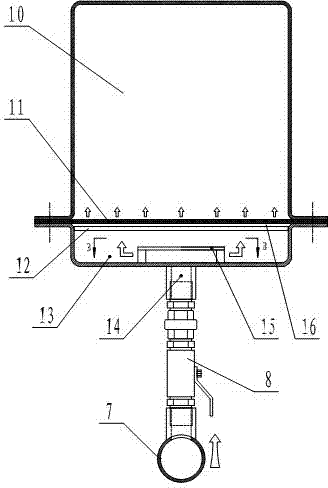

[0019] With reference to the accompanying drawings, the powder conveyor includes a powder bin 17, which is provided with a feed valve 1, the bottom of the powder bin 17 is connected with a delivery tank 3, and a discharge valve 9 is installed at the end of the delivery tank 3 to convey The trough 3 is inclined downward from the feed end to the discharge end, and its inclination angle is between 5-10°. In the conveying trough 3, there is a powder conveying bin 10 and The breathable interlayer of the lower air chamber 13, the breathable interlayer includes a support frame 12 supported on the inner wall of the delivery tank 3, and the support frame 12 is laid with a steel wire mesh 16, and the steel mesh 16 can also be replaced by other high-strength mesh materials , The steel wire mesh 16 is laid with a high-strength air-permeable cloth 11, and the high-strength air-permeable cloth 11 is a polyester air-permeable cloth. For the convenience of processing, the conveying trough 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com