Method for oxidizing styrene

A technology of styrene and oxidants, applied in organic chemistry, ozone decomposition preparation, etc., can solve problems such as harsh operating conditions, environmental pollution, equipment corrosion, etc., achieve high selectivity, increase selectivity, and overcome complex production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

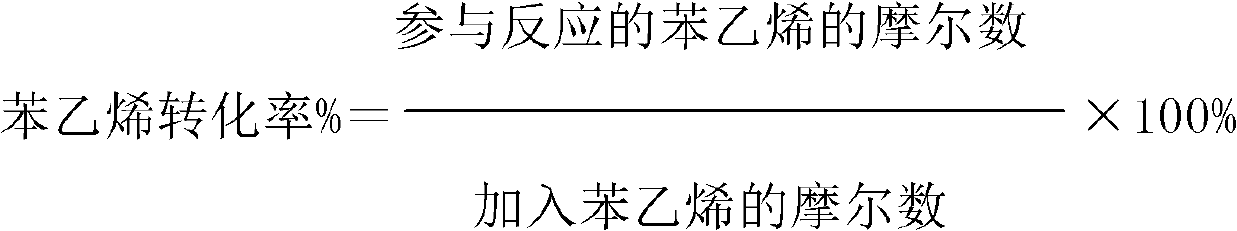

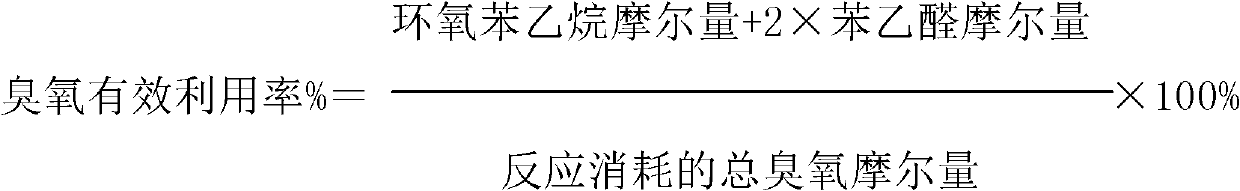

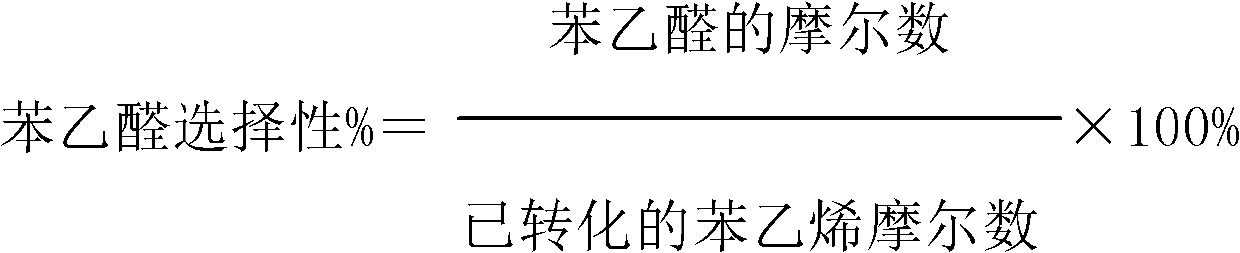

[0037] At a temperature of 60° C. and a pressure of 0.5 MPa, with ozone (15% by volume, the rest being oxygen) as an oxidant, styrene, ozone and solvent acetone were reacted in a molar ratio of 1:1:1. The results of the reaction for 2 hours are as follows: the conversion rate of styrene is 23%; the effective utilization rate of ozone is 35%; the selectivity of phenylacetaldehyde is 56% and the selectivity of styrene oxide is 8%.

Embodiment 2

[0039] At a temperature of 20° C. and a pressure of 1.5 MPa, with ozone (30% by volume, the rest being air) as an oxidant, styrene, ozone and solvent methanol were reacted in a molar ratio of 1:1:5. The results of the reaction for 2 hours are as follows: the conversion rate of styrene is 19%; the effective utilization rate of ozone is 42%; the selectivity of phenylacetaldehyde is 59% and the selectivity of styrene oxide is 16%.

Embodiment 3

[0041] At a temperature of 80° C. and a pressure of 0.2 MPa, with ozone (5% by volume, the rest being oxygen) as an oxidant, styrene, ozone and solvent acetonitrile were reacted in a molar ratio of 1:2:10. The results of the reaction for 2 hours are as follows: the conversion rate of styrene is 37%; the effective utilization rate of ozone is 33%; the selectivity of phenylacetaldehyde is 47% and the selectivity of styrene oxide is 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com