Preparation method of energy-saving and environment-friendly modified phenolic resin fireproof insulation board

A technology of fire-proof insulation board and phenolic resin, which is applied in the field of building materials, can solve the problems of secondary pollution of the environment, achieve the effects of improving strength and toughness, solving the problem of corners and waste material inventory, and reducing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

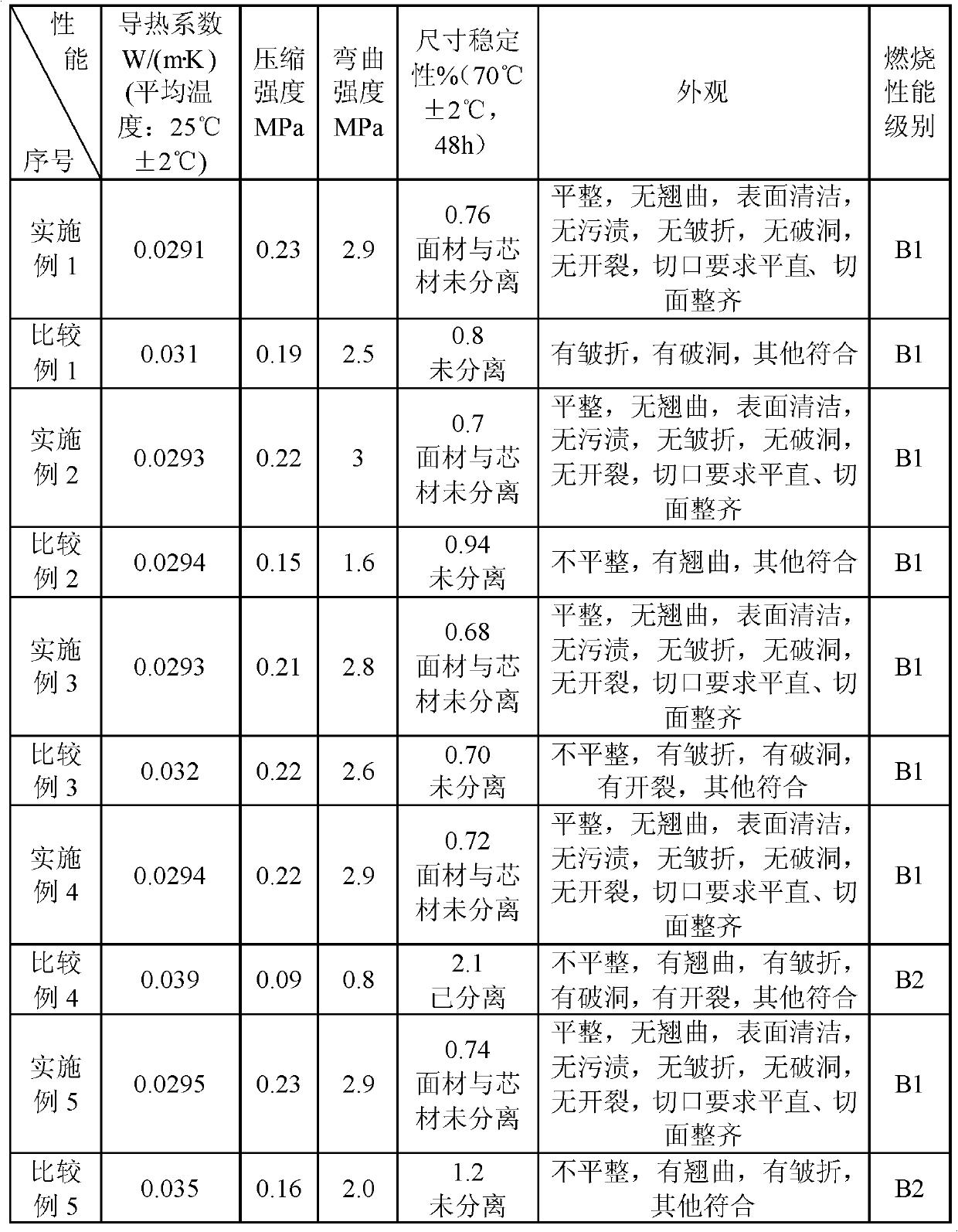

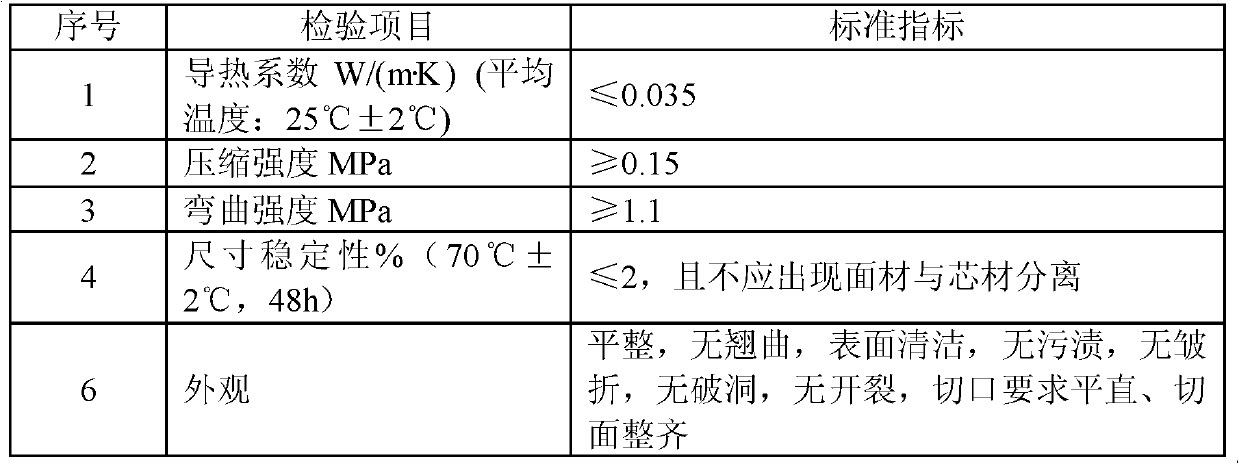

Embodiment 1

[0016] According to the mass, 10 parts of phenolic resin fire insulation board corners, waste materials, 90 parts of expandable phenolic resin, 3 parts of polyethylene glycol PEG-800 (modifier), 2 parts of H202 (surfactant), 2 parts Mix n-pentane (foaming agent) and stir evenly, then add 10 parts of xylenesulfonic acid and sulfuric acid in a mass ratio of 4:1 mixed solution (curing agent), wherein the solvent is 4:1 water:methanol, stir and pour Put it into a mold to get a phenolic resin fireproof insulation board. The specific performance is shown in Table 1.

Embodiment 2

[0018] According to the mass, 15 parts of phenolic resin fire insulation board corners, waste materials, 85 parts of expandable phenolic resin, 6 parts of polyethylene glycol PEG-800 (modifier), 4 parts of H202 (surfactant), 4 parts Mix n-pentane (foaming agent), stir evenly, then add 12 parts of xylenesulfonic acid and sulfuric acid in a mass ratio of 4:1 mixed solution (curing agent), wherein the solvent is 4:1 water:methanol, stir and pour Put it into a mold to get a phenolic resin fireproof insulation board. The specific performance is shown in Table 1.

Embodiment 3

[0020] According to the mass, 18 parts of phenolic resin fire insulation board corners and waste materials, 82 parts of expandable phenolic resin, 7 parts of polyethylene glycol PEG-1000 (modifier), 6 parts of H202 (surfactant), 6 parts Mix n-pentane (foaming agent) and stir evenly, then add 14 parts of p-xylenesulfonic acid and sulfuric acid in a mass ratio of 4:1 mixed solution (curing agent), wherein the solvent is 4:1 water:methanol, after stirring Pour it into a mold to get a phenolic resin fireproof insulation board. The specific performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com