Halogen-free environmentally-friendly phenolic moulding plastic

A phenolic molding compound, an environmentally friendly technology, applied in the field of environmentally friendly phenolic molding compounds, can solve the problems of smog damaging the environment and human health, water, soil and other environmental damage, and achieve high strength, good heat resistance and flame retardancy

Inactive Publication Date: 2013-09-11

CHANGSHU YAMEI MODEL CLOTHES RACK

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the frequent occurrence of fires, people have found that traditional halogen flame retardants have many shortcomings. The smoke released during combustion is detrimental to environmental protection and human health. After the products are discarded, the harmful flame retardants in the products will spread to the environment along with the products. cause damage to water bodies, soil and other environments

The usual practice is to control the content of halogen added to the material, that is, the content of halogen is usually controlled at 900ppm, but practice has proved that this addition is difficult to show a satisfactory balance between flame retardancy and environmental protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

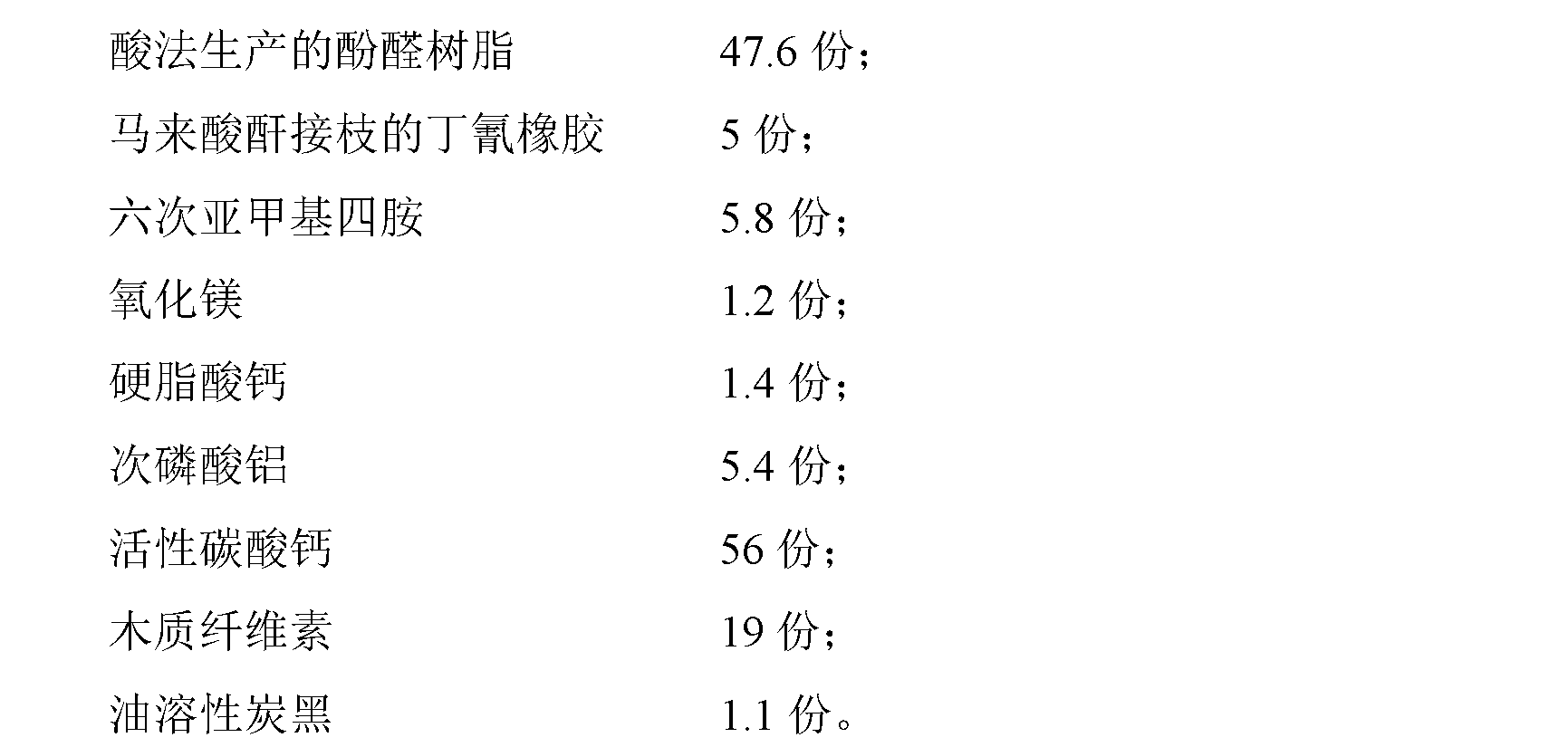

Embodiment 1

[0017]

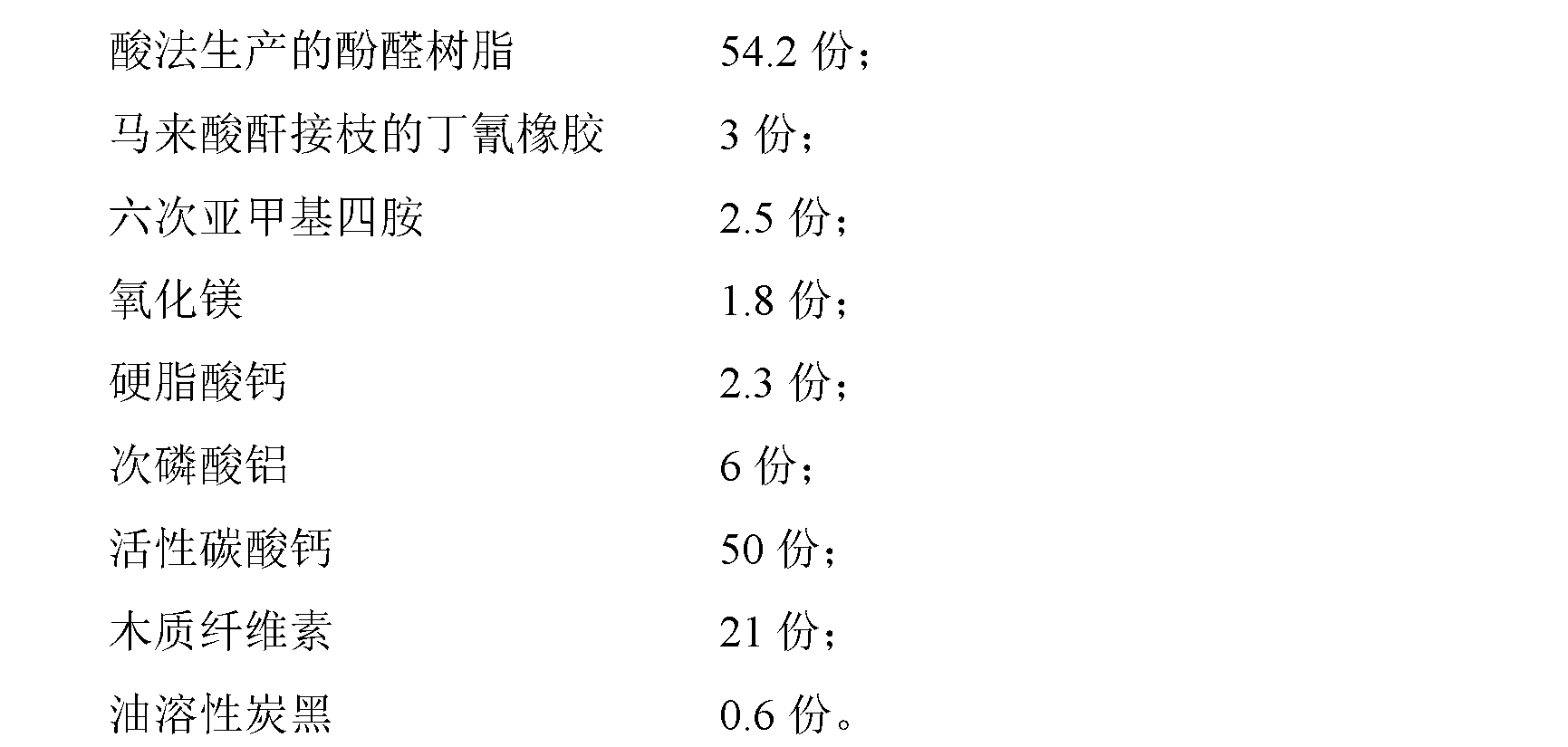

Embodiment 2

[0019]

Embodiment 3

[0021]

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Login to View More

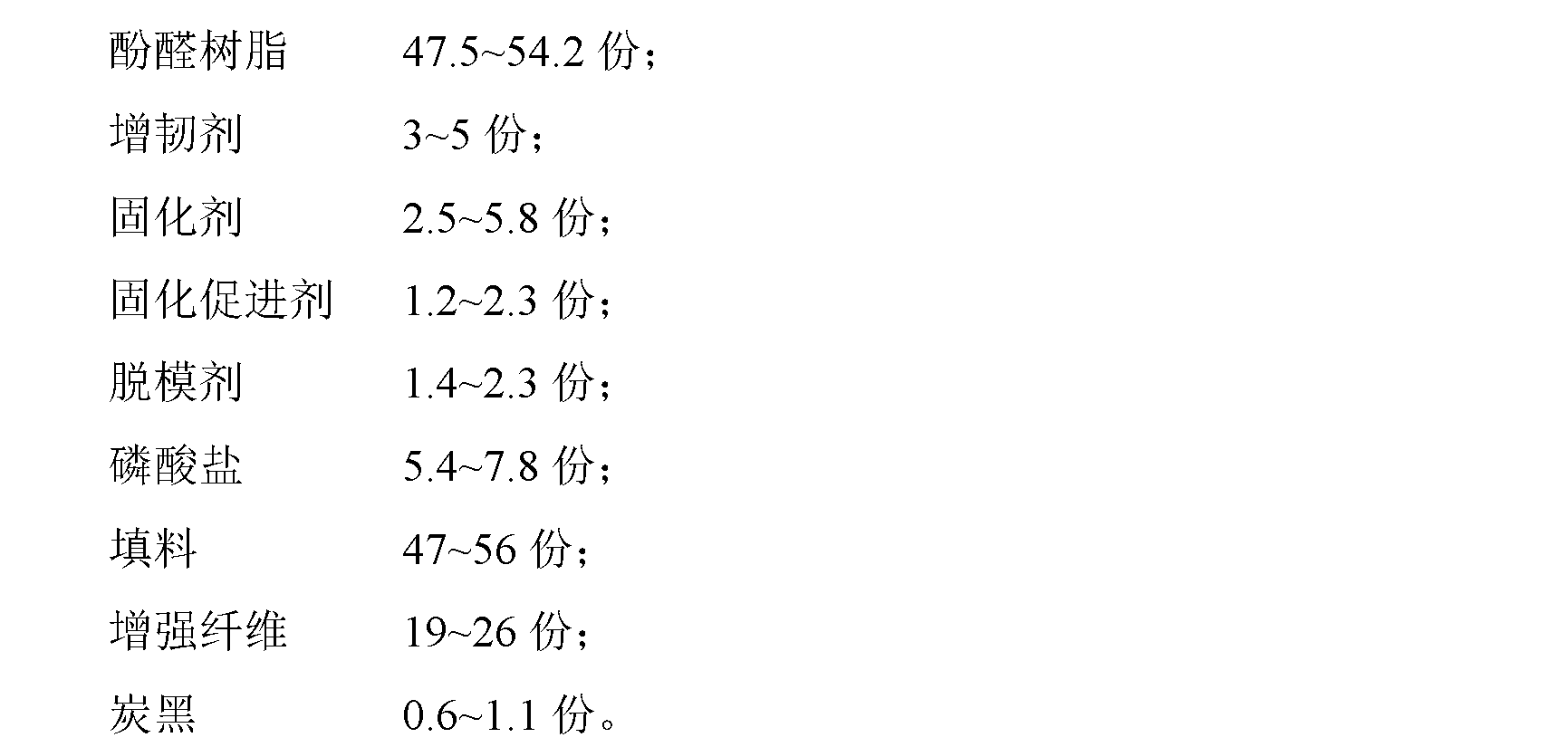

Abstract

The invention provides a halogen-free environmentally-friendly phenolic moulding plastic and belongs to the technical field of high-polymer materials. The halogen-free environmentally-friendly phenolic moulding plastic is prepared from the following raw materials in parts by weight: 47.5-54.2 parts of phenolic resin, 3-5 parts of flexibilizer, 2.5-5.8 parts of curing agent, 1.2-2.3 parts of curing accelerator, 1.4-2.3 parts of demoulding agent, 5.4-7.8 parts of phosphate, 47-56 parts of filler, 19-26 parts of reinforced fibers, and 0.6-1.1 parts of carbon black. The halogen-free environmentally-friendly phenolic moulding plastic has the characteristics of being good in thermal resistance and flame retardance, high in strength, and environmentally-friendly, and can achieve the bending strength of 90-110MPa, the thermal deformation temperature of 215-228 DEG C, the flame retardance property of UL-94-V-0 level (3mm), and the gap impact strength of 3-4kj / m<2>.

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to a halogen-free environment-friendly phenolic molding compound. Background technique [0002] Phenolic resin is obtained by polycondensation reaction of phenol and formaldehyde under an acid catalyst, and various materials with practical application value can be made by adding other necessary components. With the frequent occurrence of fires, people have found that traditional halogen flame retardants have many shortcomings. The smoke released during combustion is detrimental to environmental protection and human health. After the products are discarded, the harmful flame retardants in the products will spread to the environment along with the products. Cause damage to water bodies, soil and other environments. The usual practice is to control the content of halogen added to the material, that is, the content of halogen is usually controlled at 900ppm, but p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L61/06C08L97/02C08K13/02C08K5/17C08K3/22C08K5/098C08K3/32C08K3/26

Inventor 金蒙娜金惠良

Owner CHANGSHU YAMEI MODEL CLOTHES RACK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com