Method for preparing highlight colored paint plate by using electron beam radiation curing technology

A technology of electron beam radiation and high-gloss color paint board, which is applied in the direction of coating, epoxy resin coating, polyester coating, etc., can solve the problems of high product formulation cost, bad smell, difficult to do, etc., and achieve production efficiency High, no inert atmosphere, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

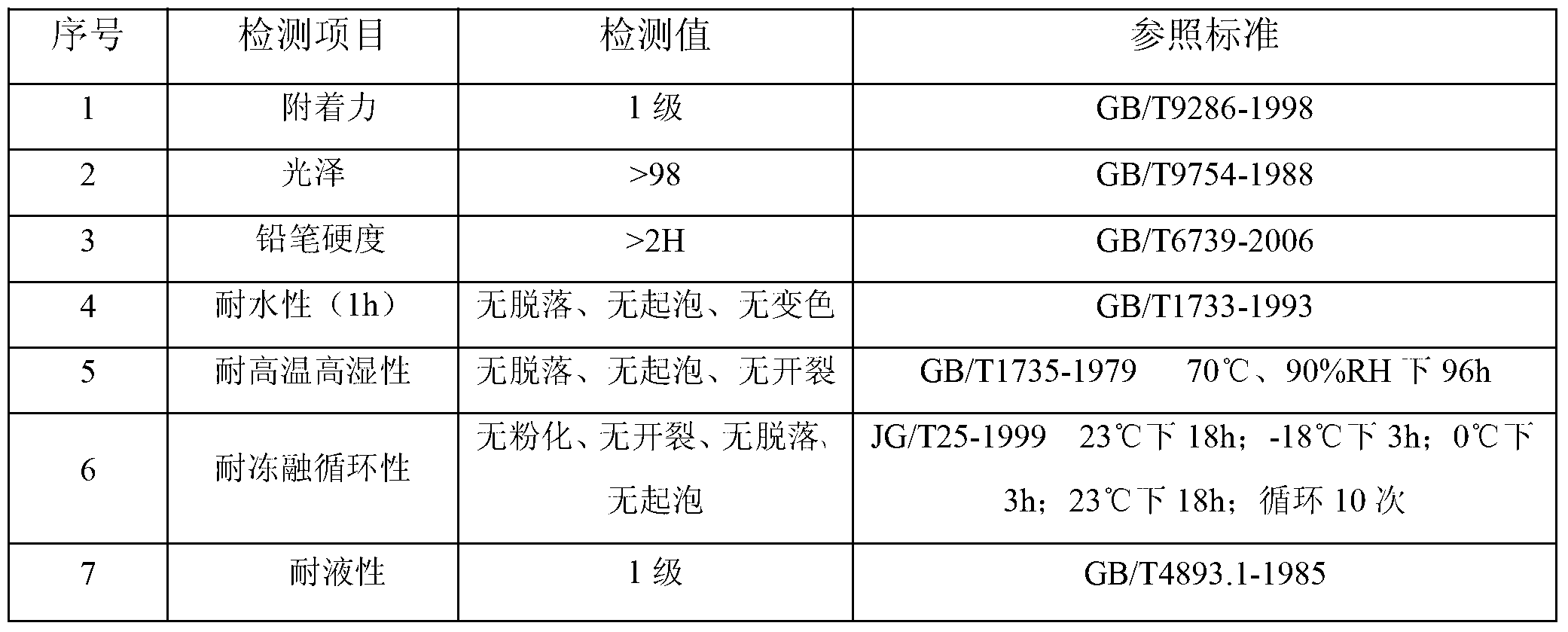

Examples

Embodiment 1

[0023] [Example 1] A method utilizing electron beam radiation curing technology to prepare a high-gloss color paint panel, is characterized in that it comprises the following steps:

[0024] S1: Base material pretreatment: thickness setting 50mm, sanding, dust removal;

[0025] S2: Color paint compounding:

[0026] S21: Preparation of electron beam curing color paint: electron beam curing color paint is composed of the following raw materials in parts by weight: resin 30, reactive monomer 15, polymer dispersant 2, pigment 20, filler 10, the total amount of resin is 1 / 3 , 1 / 2 of the total amount of reactive monomers, pigments, and polymer dispersants are mixed. After being ground and dispersed by a ball mill, the remaining resin, remaining reactive monomers, and fillers are added, and stirred at high speed for 25 minutes to obtain electron beam curing Paint;

[0027] S22: Electron beam curing high-gloss paint preparation: electron beam curing high-gloss paint consists of the ...

Embodiment 2

[0037] [Example 2] A method utilizing electron beam radiation curing technology to prepare high-gloss color paint panels, is characterized in that it comprises the following steps:

[0038] S1: Substrate pretreatment: thickness setting 3mm, sanding, dust removal;

[0039] S2: Color paint compounding:

[0040] S21: Preparation of electron beam curing color paint: electron beam curing color paint is composed of the following raw materials in parts by weight: resin 40, reactive monomer 30, polymer dispersant 3, pigment 25, filler 20, the total amount of resin is 1 / 3 , 1 / 2 of the total amount of reactive monomers, pigments, and polymer dispersants are mixed. After being ground and dispersed by a ball mill, the remaining resin, remaining reactive monomers, and fillers are added, and stirred at high speed for 27 minutes to obtain electron beam curing Paint;

[0041] S22: electron beam curing high-gloss paint preparation: electron beam curing high-gloss paint consists of the follow...

Embodiment 3

[0051] [Example 3] A method utilizing electron beam radiation curing technology to prepare high-gloss color paint panels, is characterized in that it comprises the following steps:

[0052] S1: Base material pretreatment: thickness setting 25mm, sanding, dust removal;

[0053] S2: Color paint compounding:

[0054] S21: Preparation of electron beam curing color paint: electron beam curing color paint is composed of the following raw materials in parts by weight: resin 50, vinyl ether reactive monomer 35, polymer dispersant 5, pigment 30, filler 30, the resin total 1 / 3 of the total amount of reactive monomers, 1 / 2 of the total amount of reactive monomers, pigments, and polymer dispersants are mixed. After being ground and dispersed by a ball mill, the remaining resin, remaining reactive monomers, and fillers are added, and stirred at high speed for 35 minutes to prepare Obtain electron beam curing color paint;

[0055] S22: electron beam curing high-gloss paint preparation: el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com