Dry distiller and oil sand pyrolysis-dry distillation system

A technology of retort and retort, which is applied in special forms of retort, petroleum industry, coke oven, etc., to achieve the effect of improving the effect and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the present invention, the preferred embodiments of the present invention will be described below in conjunction with examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

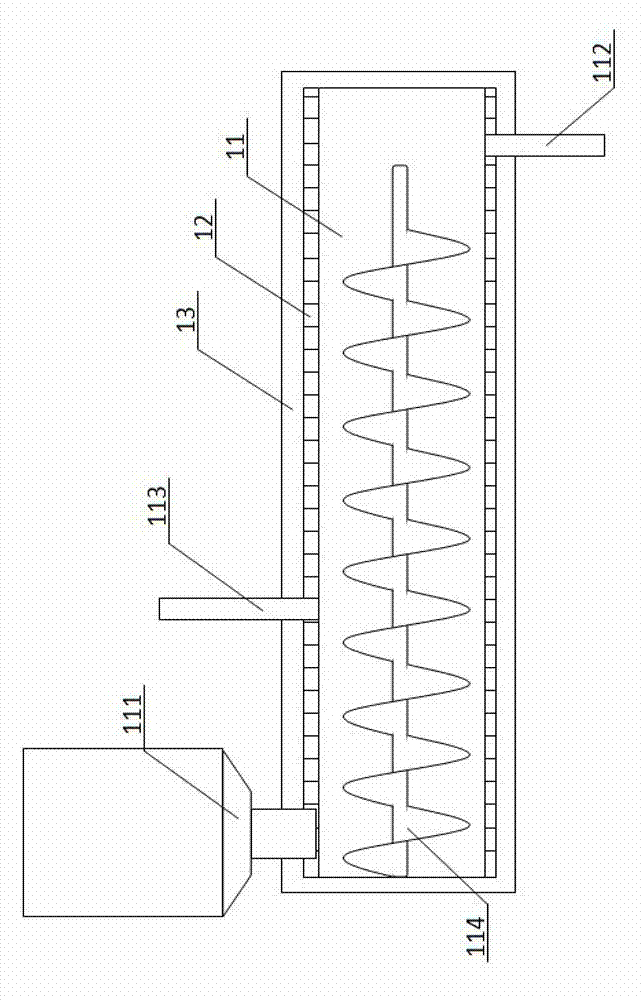

[0035] The invention provides a retort, which includes a cylinder and a heating device for heating the cylinder;

[0036] One end of the cylinder is provided with a feed inlet, and the other end is provided with a solid outlet;

[0037] A gas outlet is arranged on the cylinder, and the gas outlet is arranged near one end of the feed inlet;

[0038] An auger is arranged inside the barrel, and one end of the auger is fixed on the side of the barrel close to the feeding port.

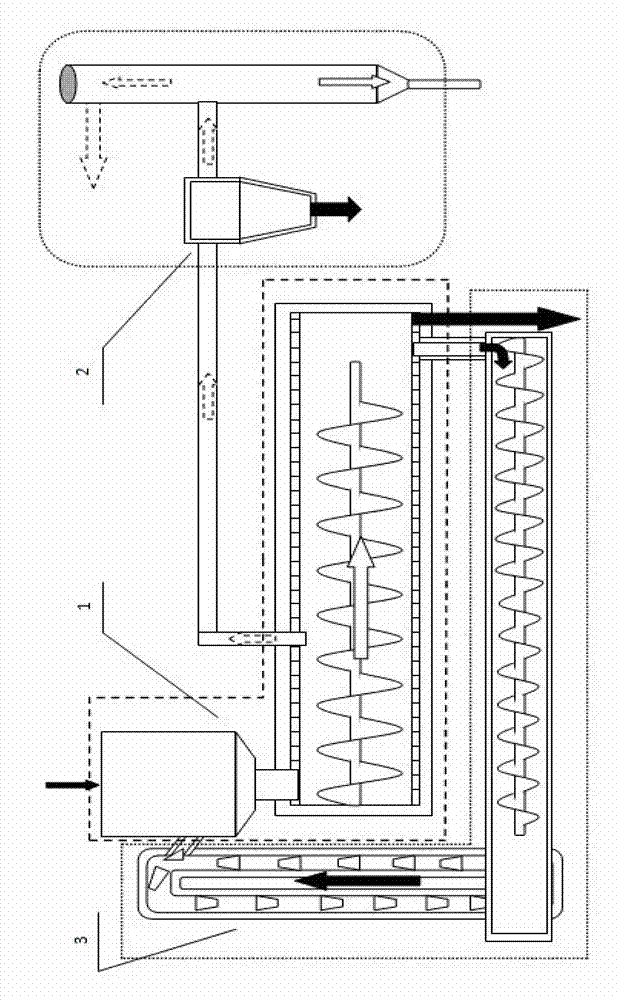

[0039] See figure 1 , figure 1 This is a schematic diagram of the structure of the retort provided by an embodiment of the present invention, where 11 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com