Microwave pyrolysis furnace suitable for dry distillation of coal material

A technology for pyrolysis furnace and coal material, which is applied in the field of retorting furnace for coal material, can solve the problems of high investment and production cost, large energy consumption, unreasonable furnace structure design, etc. The effect of solving the limitation of penetrating coal and improving the yield of pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

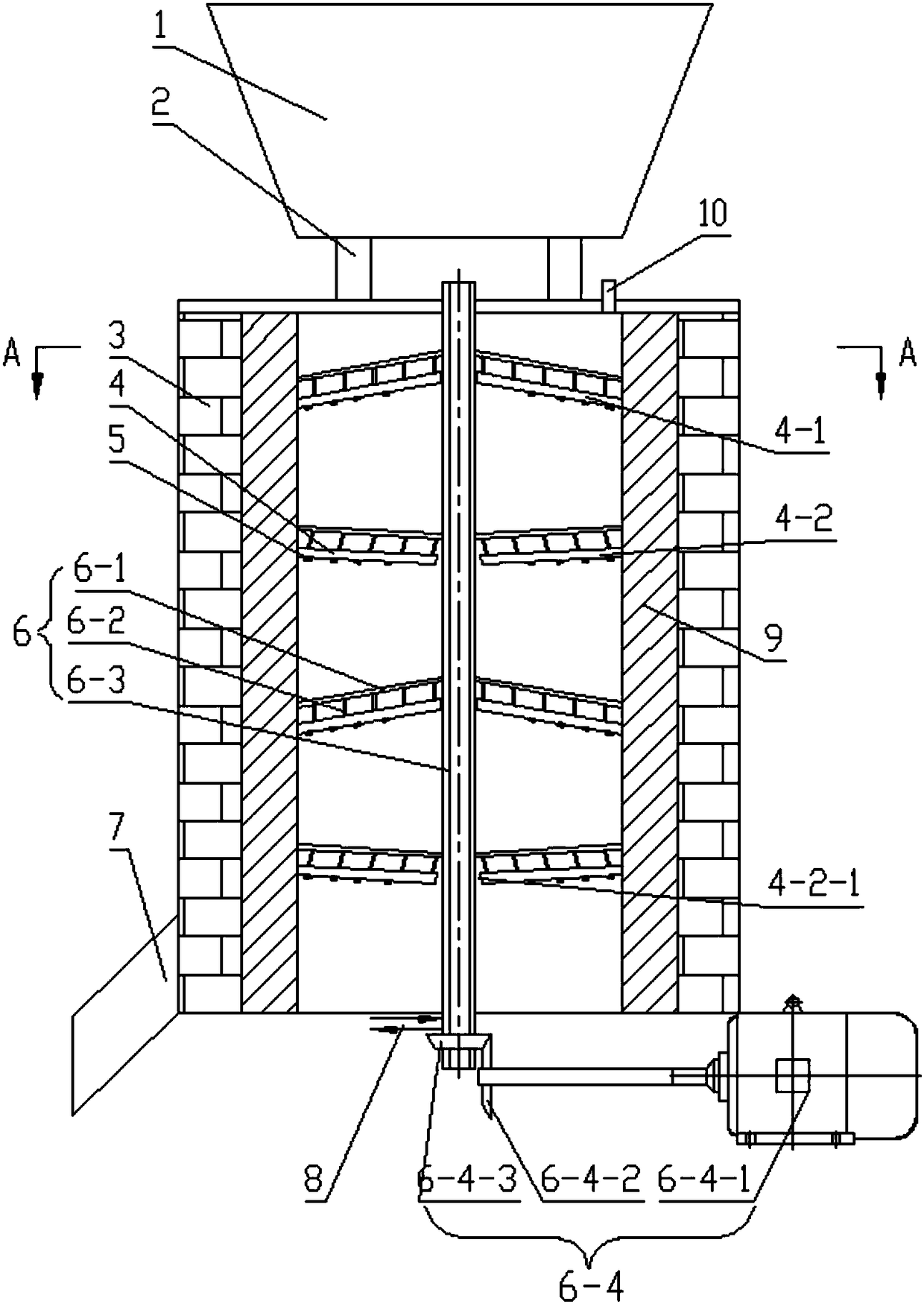

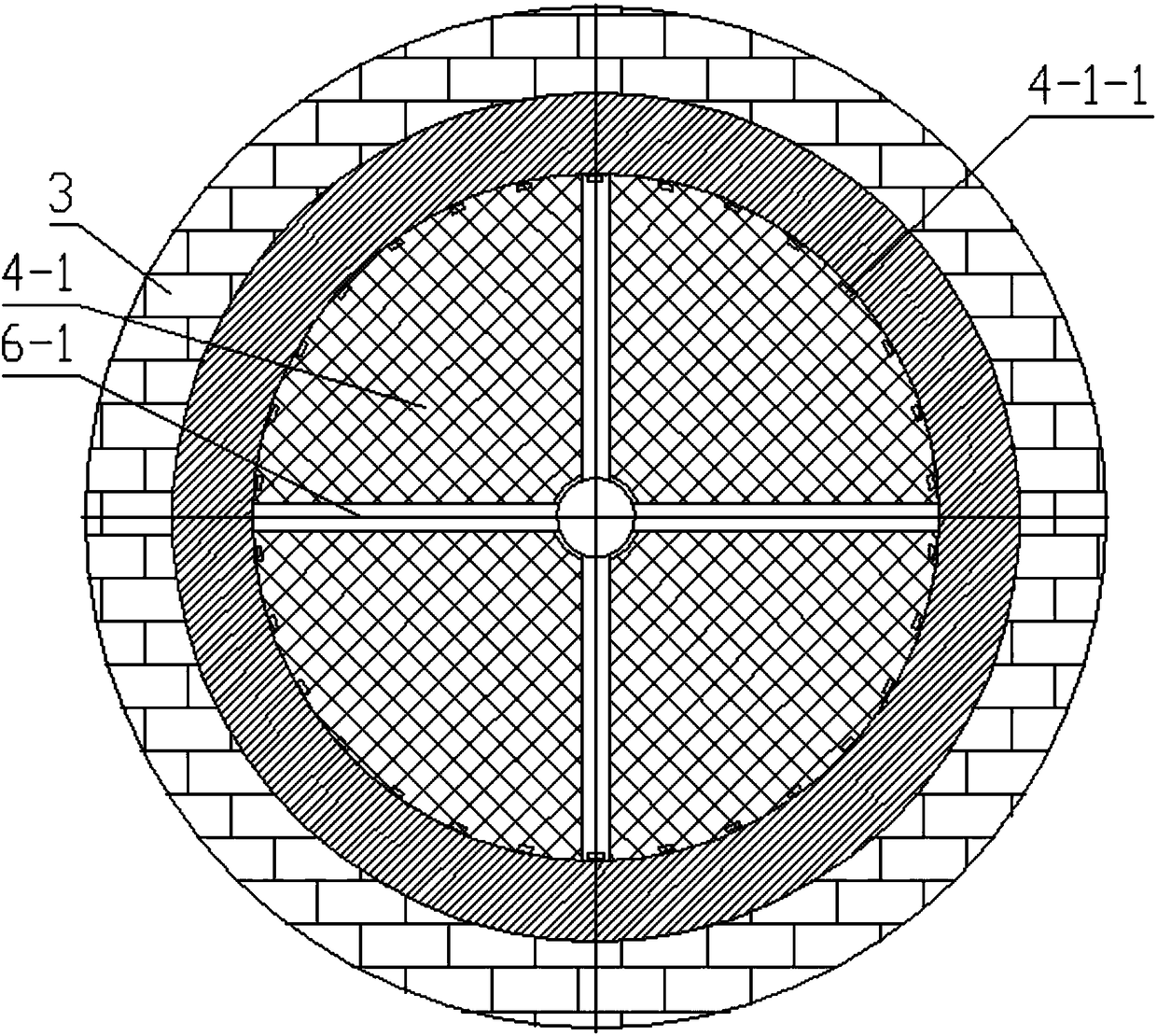

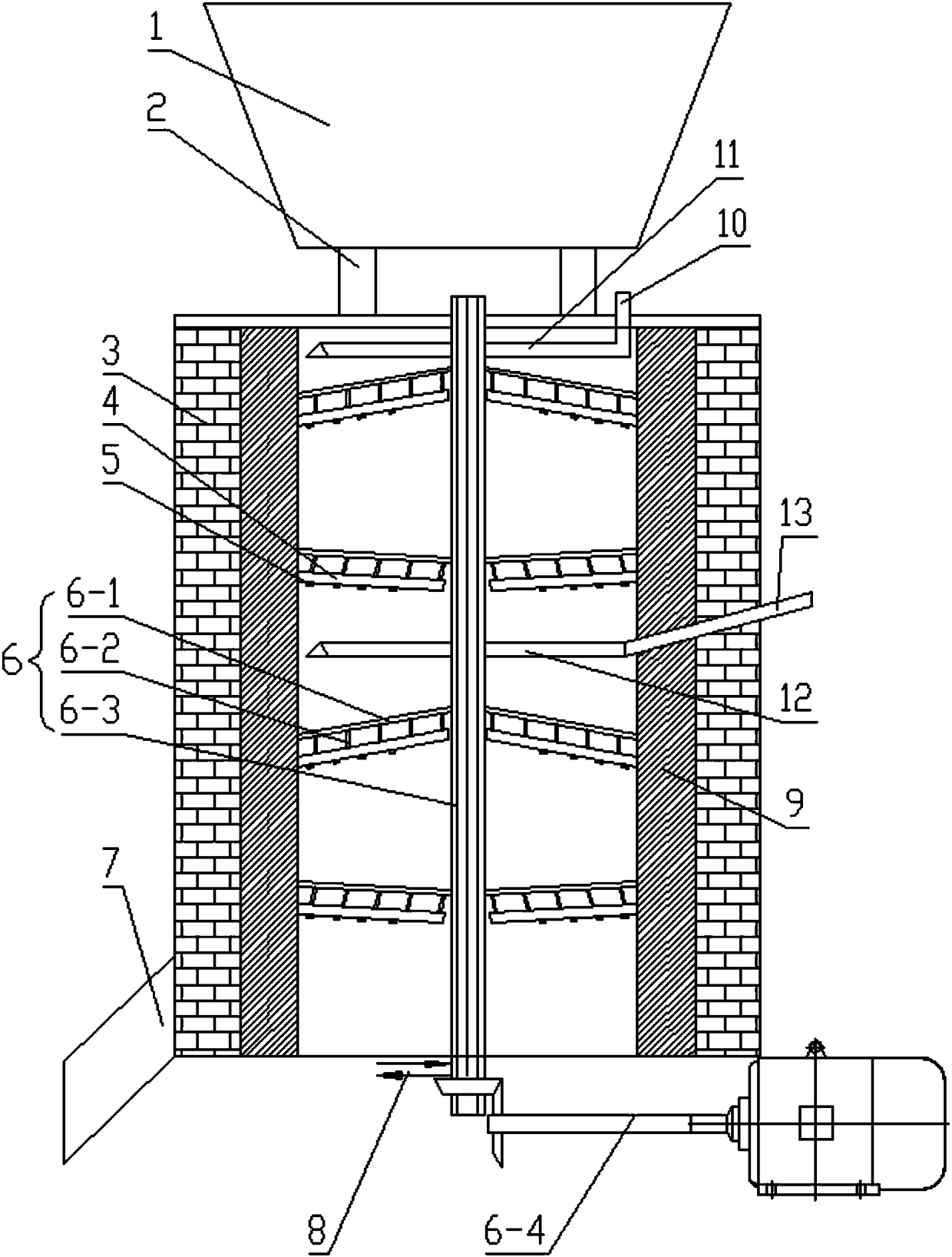

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0025] The invention provides a microwave pyrolysis furnace suitable for dry distillation of coal materials, such as Figure 1 to Figure 3 As shown, it includes a furnace body 3, a hopper 1 located above the furnace body 3, and a discharge hopper 7 located below the furnace body. The inner wall of the furnace body 3 is provided with a plurality of material beds 4 arranged up and down for storing coal materials. , all the material beds 4 are inclined from the inner side wall of the furnace body 3 to extend toward the center of the furnace body 3, and each material bed 4 is also provided with a number of feeding openings that can make the coal materials fall, and each material bed 4 is provided with A rotating device 6 capable of laying the coal on the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com