Method and device for producing thermoelectric conversion material and method for producing sputtering target

A technology of thermoelectric conversion materials and sputtering targets, which is applied in the direction of thermoelectric device node lead wire materials, sputtering plating, metal material coating technology, etc., can solve the problem of high cost, difficult to uniformly distribute doped elements, crystal defects etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

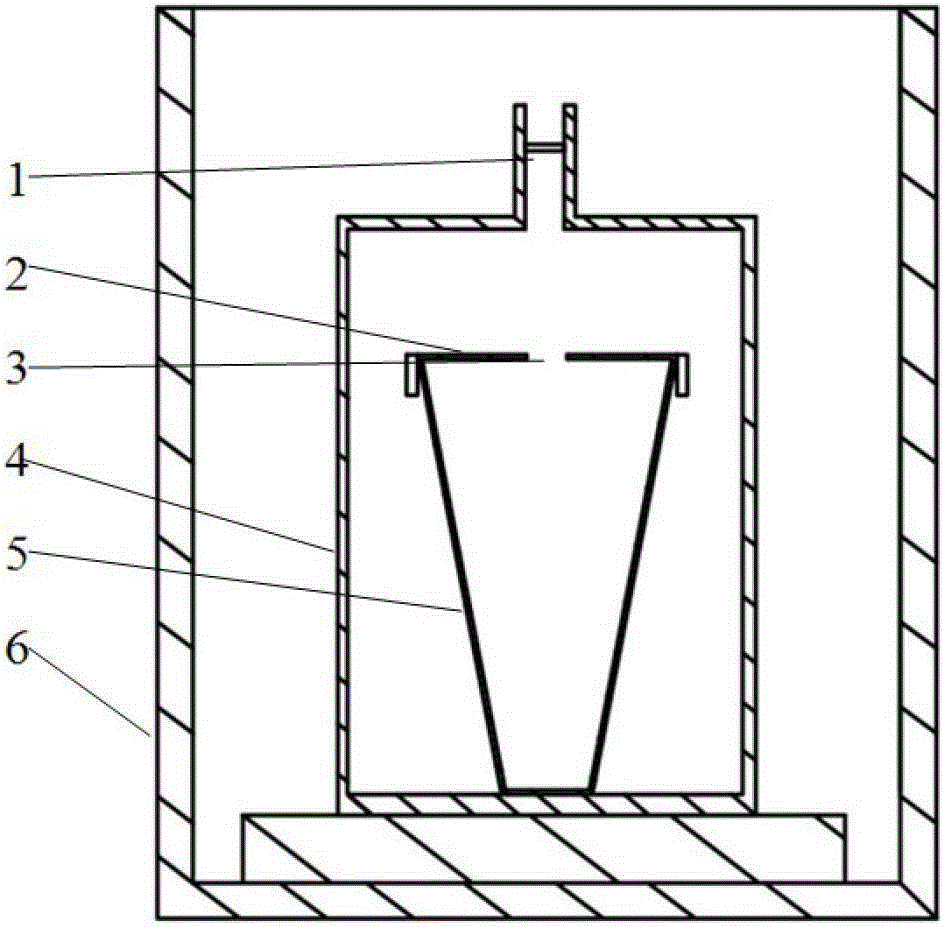

Image

Examples

Embodiment 1

[0038] First put bismuth (Bi), 57.7% tellurium (Te) and 27.3% antimony (Sb) with a weight ratio of 15.0% into the same crucible; the crucible is usually made of quartz or zirconia and other materials; this The composition of these components forms Bi 0.5 Sb 1.5 Te 3 metal compound.

[0039] Place the crucible in a stainless steel vacuum vessel. The vacuum container is then placed in a well-type electric furnace, or placed directly in a vacuum well-type electric furnace.

[0040] Vacuumize the vacuum container or well-type vacuum electric furnace directly to make the vacuum degree in the container reach 1×10 -1 Pa to 1×10 -3 Pa, then seal the exhaust pipe or turn off the vacuum valve. During the heating process and the reaction process under high temperature conditions, vacuum is not applied.

[0041] The material in the crucible is heated by electromagnetic induction. Heating from room temperature to 590°C to 610°C, the heating rate is controlled at 90°C / hour to 100°C / ...

Embodiment 2

[0044] First, 0% bismuth (Bi), 40% antimony (Sb) and 60% tellurium (Te) are put into the same crucible according to the weight ratio; the crucible is usually made of materials such as quartz or zirconia.

[0045] Place the crucible in a stainless steel vacuum vessel. The vacuum container is then placed in a well-type electric furnace, or placed directly in a vacuum well-type electric furnace.

[0046] Vacuumize the vacuum container or well-type vacuum electric furnace directly to make the vacuum degree in the container reach 1×10 -1 Pa to 1×10 -3 Pa, then seal the exhaust pipe or turn off the vacuum valve. Vacuum was not applied during heating and during high temperature reactions.

[0047] The material in the crucible is heated by electromagnetic induction. Heating from room temperature to 630°C to 650°C, the heating rate is controlled at 90°C / hour to 100°C / hour. Keep at this temperature for 165 minutes to 185 minutes.

[0048] Let the raw materials in the crucible full...

Embodiment 3

[0050]First, 15% bismuth (Bi), 60% tellurium (Te) and 25% antimony (Sb) are put into the same crucible according to the weight ratio; the crucible is usually made of materials such as quartz or zirconia.

[0051] Place the crucible in a stainless steel vacuum vessel. The vacuum container is then placed in a well-type electric furnace, or placed directly in a vacuum well-type electric furnace.

[0052] Vacuumize the vacuum container or well-type vacuum electric furnace directly to make the vacuum degree in the container reach 1×10 -1 Pa to 1×10 -3 Pa, then seal the exhaust pipe or turn off the vacuum valve. During heating and high temperature reaction, no vacuum is applied.

[0053] The material in the crucible is heated by electromagnetic induction. Heating from room temperature to 630°C to 640°C, the heating rate is controlled at 80°C / hour to 100°C / hour. Keep at this temperature for 180 minutes to 195 minutes.

[0054] Let the raw materials in the crucible fully react u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com