High-pressure measuring pump device for conveying viscous liquids

A high-pressure metering pump and viscous liquid technology, applied in the field of high-pressure metering pumps, can solve the problems of affecting the sealing performance of one-way valve, unable to form high pressure, difficult to transport viscous liquid, etc., and achieve the effect of reducing viscosity and improving infusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

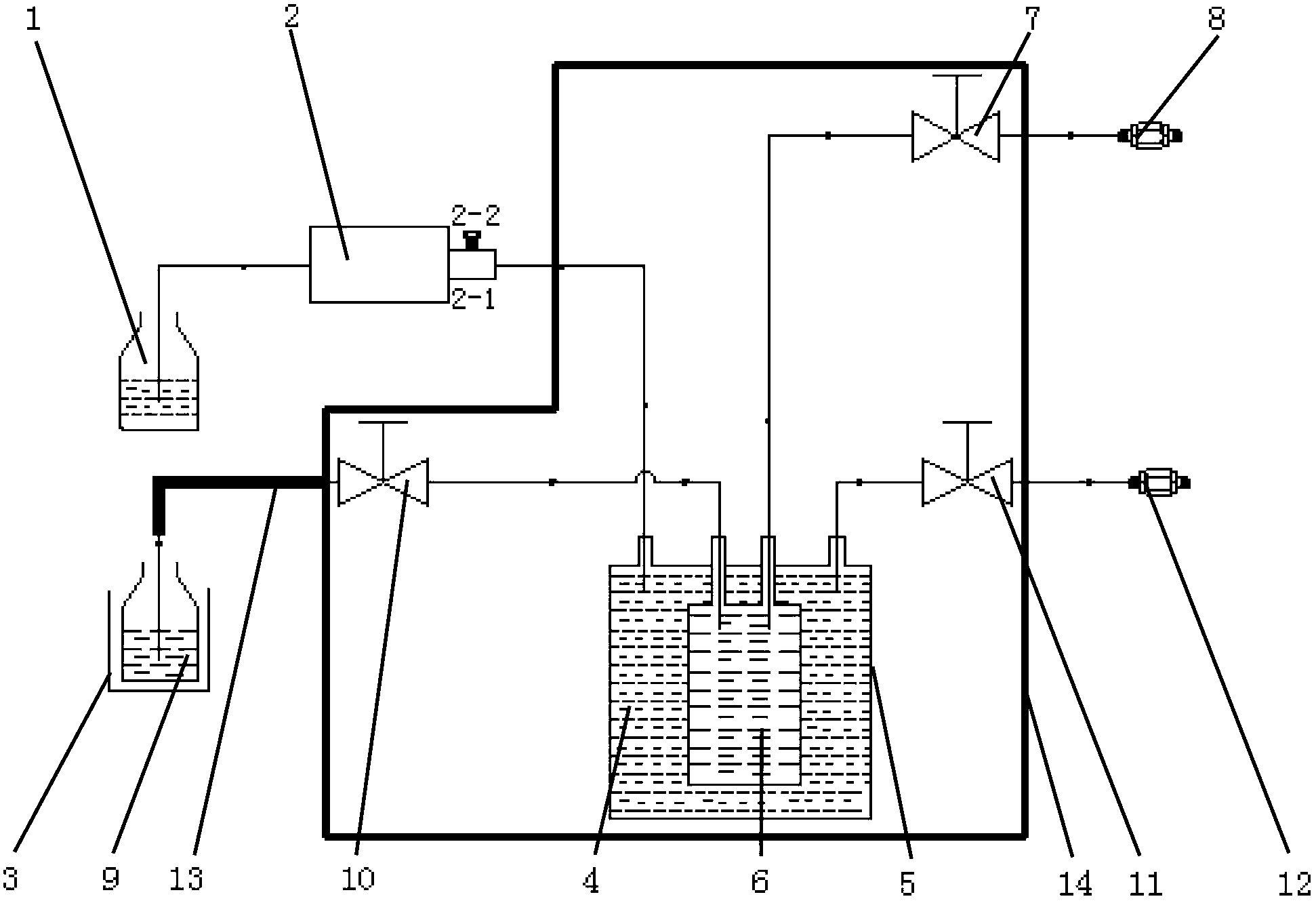

[0039] Such as figure 1 As shown, it is a schematic structural diagram of a high-pressure metering pump device for transporting viscous liquid (coal tar) according to the present invention, including a liquid bottle 1 for transmitting power, a plunger pump 2, a vent valve 2-1, and a waste liquid outlet 2-2 , high-pressure power transmission equipment 5, high-pressure power transmission equipment 5 is composed of compartment bag chamber 4 and compartment bag 6, infusion valve 7, liquid outlet 8, viscous liquid bottle 9, liquid storage inlet valve 10, metering valve 11, metering port 12, insulation pipe 13, heating insulation box 14, heating jacket 3.

[0040] The power transmission liquid bottle 1 containing ethanol is connected to the inlet end of the plunger pump 2, and the outlet end of the plunger pump 2 is connected to the inlet of the compartment 4 of the high-pressure power transmission device 5, and the compartment of the high-pressure power transmission device 5 The e...

Embodiment 2

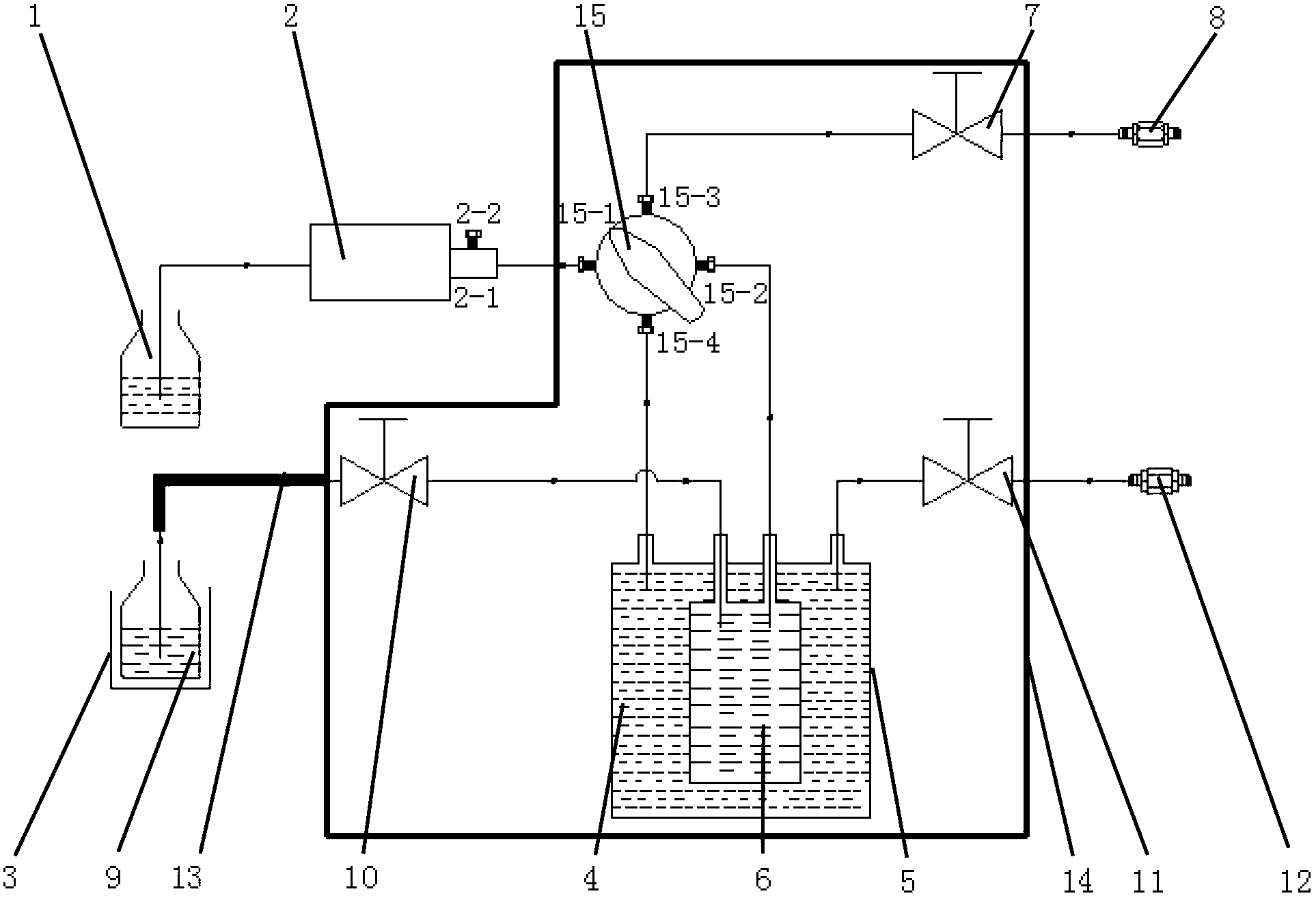

[0042] Such as figure 2 Shown is a schematic structural diagram of a high-pressure metering pump device for transporting viscous liquid (paraffin) according to the present invention, including a liquid bottle 1 for transmitting power, a plunger pump 2, a vent valve 2-1, and a waste liquid outlet 2-2 , the mode switching ball valve 15, which is provided with four valve ports, respectively the first valve port 15-1, the second valve port 15-2, the third valve port 15-3 and the fourth valve port 15-4, high pressure Power transmission equipment 5, compartment bag room 4, compartment bag 6, infusion valve 7, liquid outlet 8, viscous liquid bottle 9, liquid storage inlet valve 10, metering valve 11, metering port 12, insulation tube 13, heating insulation box 14. Heating jacket 3.

[0043] The power transmission liquid bottle 1 filled with water is connected to the inlet port of the plunger pump 2, the outlet port of the plunger pump 2 is connected to the first valve port 15-1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com