A small load high speed, large load low speed cylinder

A large load, small load technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of long stroke of the main cylinder, low production efficiency, long time period, etc., to improve productivity, reduce energy waste, and shorten the working cycle time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention relates to the technical field of energy saving of equipment such as balers or slag removal machines, specifically, without adding additional large investment, by making some improvements to the existing equipment oil cylinder and control circuit, the working cycle can be shortened, productivity can be improved, The purpose of reducing energy waste.

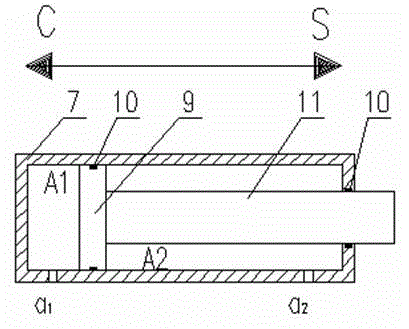

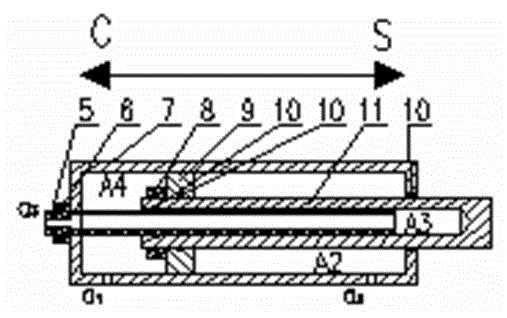

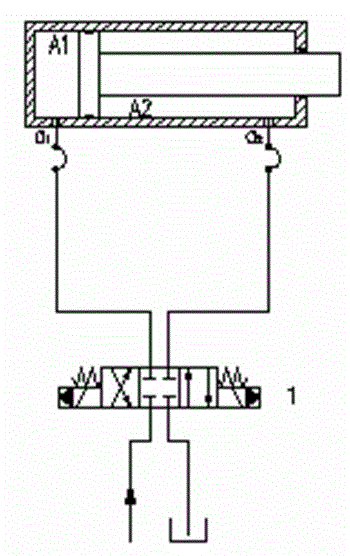

[0020] see figure 2 , Figure 4 , the concrete structure of a kind of small-load high-speed, big-load low-speed cylinder that the present invention relates to is:

[0021] Including a cylinder 7, a piston 9, a seal ring 10, a hollow first piston rod 5, a hollow second piston rod 11 and a control circuit for controlling the expansion and contraction of the oil cylinder; wherein,

[0022] One end of the second piston rod 11 is connected with the piston 9 in the cylinder body 7, and the other end passes through the cylinder body 7; one end of the first piston rod 5 is connected with the cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com