Spaceflight thermal protection material

A thermal protection material and material technology, applied in the aerospace field, can solve the problems of not being able to effectively cut off the direct contact of the film, reduce the isolation effect of the heat insulation mesh pad, and increase the overall mass of the laminated structure, so as to improve the dynamic thermal protection performance and reduce the Adverse effects, effects of maintaining smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The heat protection material of the present invention will be described in detail below with reference to the drawings and examples.

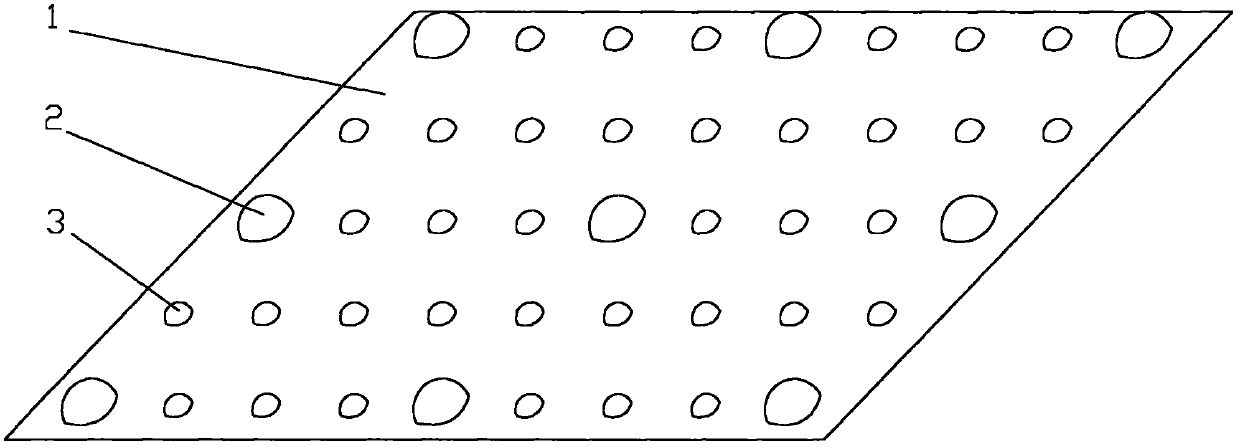

[0010] Such as figure 1 As shown, on the aluminum-coated film substrate, there are bubble structures of different sizes distributed, and the bubbles contain a certain amount of pure inert gas, such as pure and dry nitrogen or carbon dioxide.

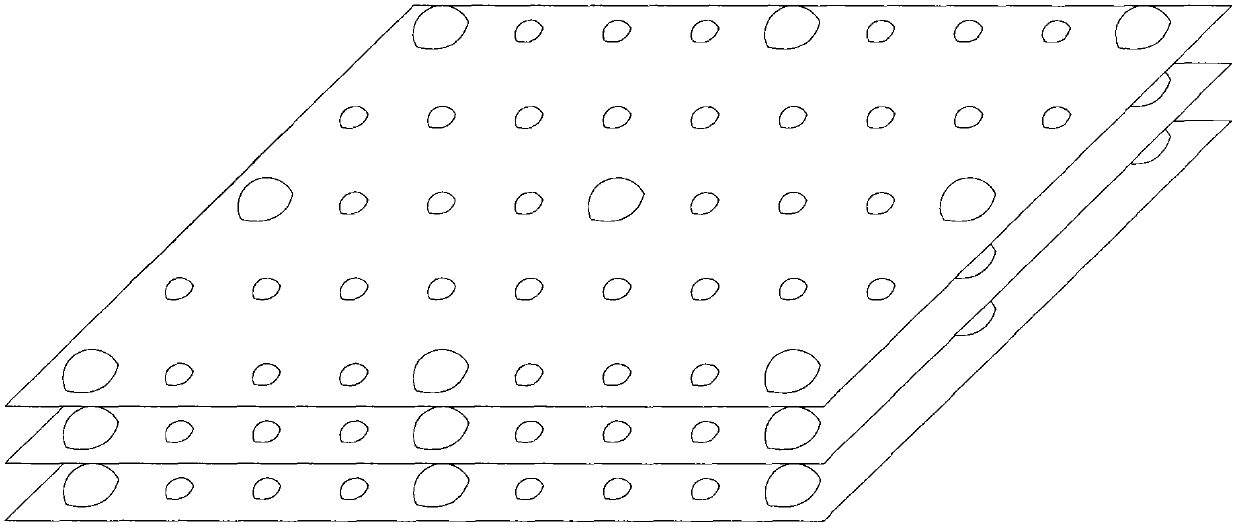

[0011] figure 2 In the shown embodiment of the heat protection structure, a heat protection structure with three layers of materials is used. The large air bubbles on the aluminized film substrate play an isolation role, reducing the contact area between the films, thereby reducing heat conduction. The small bubbles mainly play the role of auxiliary isolation, increasing the heat capacity of the material, and improving the dynamic thermal protection performance of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com