Device and method for reducing generating and discharging of sintered dioxin

A sintering machine and bellows technology, applied in lighting and heating equipment, waste heat treatment, furnaces, etc., can solve the problems of high operating costs, inability to fully meet, large initial investment, etc., to reduce sintering exhaust gas and dioxin emissions. The effect of reducing the purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

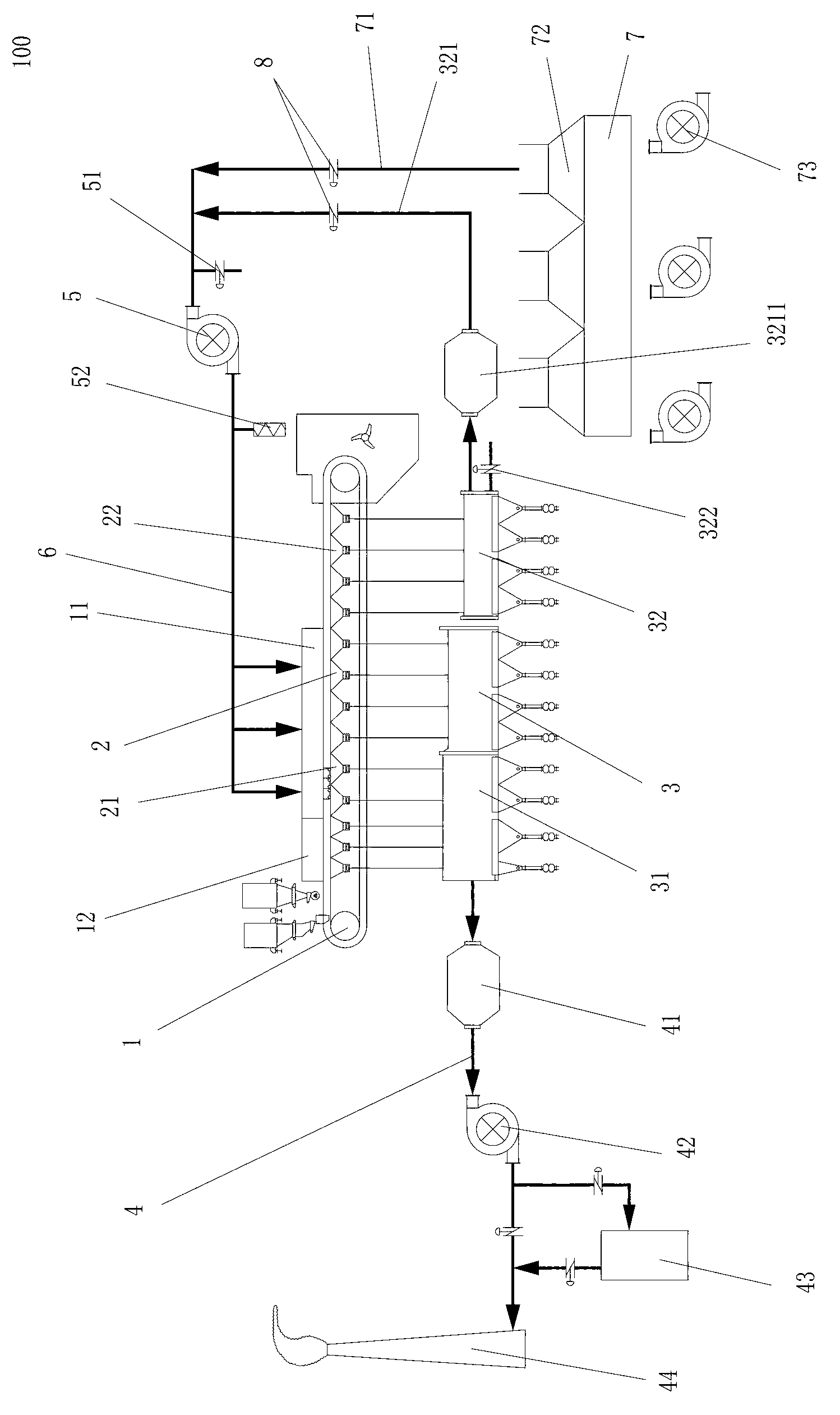

[0020] Such as figure 1 As shown, the present invention proposes a device 100 for reducing the generation and emission of sintering dioxins; the device 100 includes a sintering machine 1, a sintering machine bellows 2, and a sintering machine large flue 3 communicating with the sintering machine bellows. An igniter 12 is provided on the sintering machine; in this embodiment, the large flue 3 of the sintering machine is divided into two sections of mutually independent exhaust flue 31 and circulating flue 32; 21, the circulating flue 32 communicates with the air box 22 in the rear section of the sintering machine; the outlet of the exhaust flue 31 communicates with the exhaust pipe 4, and the exhaust gas generated in the front sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com