Vector control method for single current sensor

A vector control and sensor technology, applied in the field of vector control, can solve problems such as the inability to realize current decoupling transformation, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

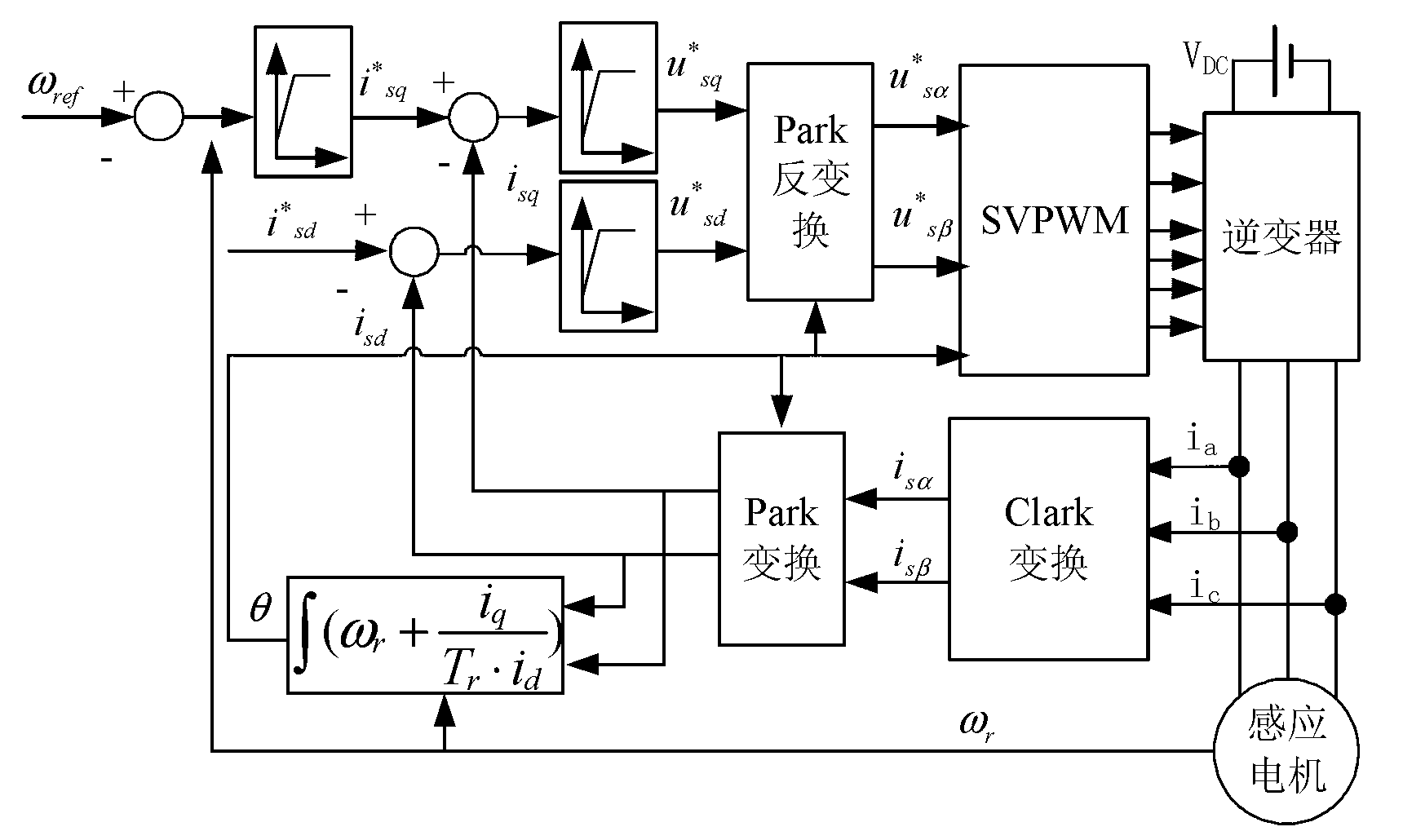

[0027] Specific implementation mode one: combine figure 1 Describe this embodiment, the single current sensor vector control method described in this embodiment,

[0028] The vector control method is realized based on the measurement of any phase current of the stator by a single current sensor. Taking the realization of the phase a current of the stator by a single current sensor as an example, the method includes the following steps:

[0029] Step 1: Use a voltage sensor to measure the DC bus voltage V DC , according to the current moment SVPWM modulation output 6 IGBT drive signals to reconstruct the stator three-phase voltage u A , u B and u C , and use the current sensor to measure the stator a-phase current i α ;

[0030] Step 2: Transform the stator three-phase voltage u obtained in Step 1 by using Clark transformation A , u B , u C and stator a-phase current i α Transform from the static three-phase coordinate system to the static αβ coordinate system to obtai...

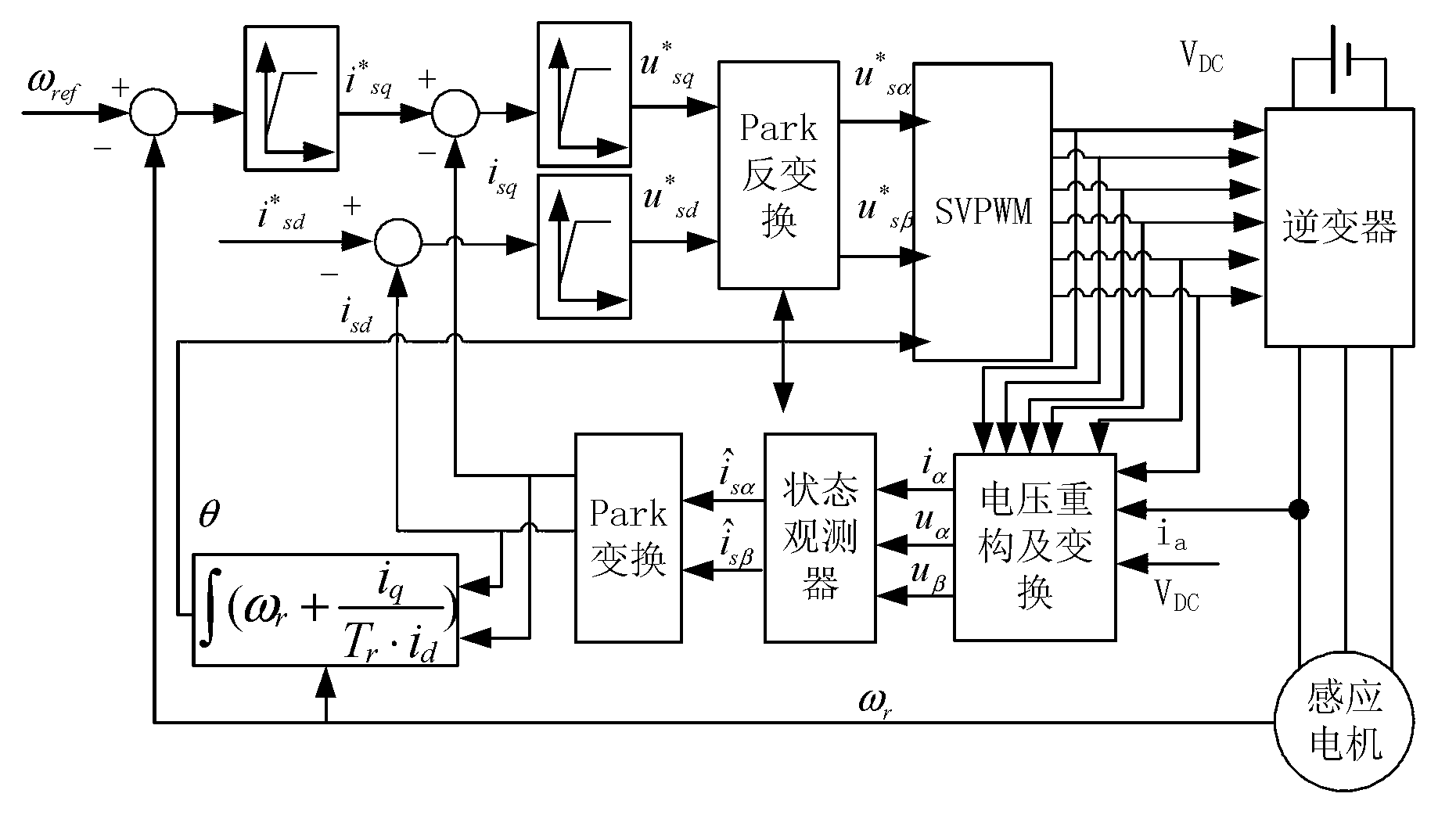

specific Embodiment approach 2

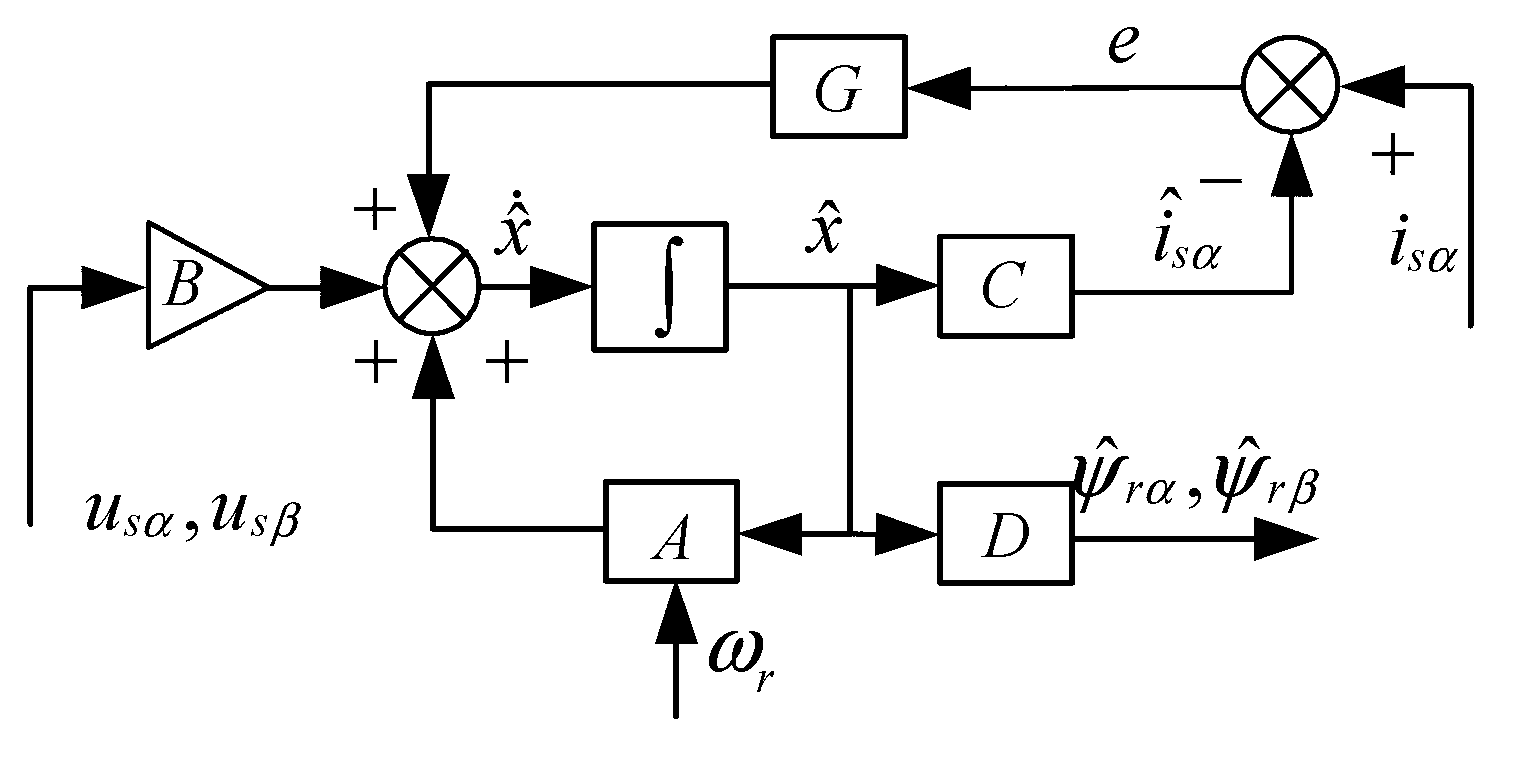

[0045] Specific implementation mode two: combination image 3 Describe this embodiment, this embodiment is a further limitation of the single current sensor vector control method described in the first specific embodiment,

[0046] In the step 3, the stator α-axis current vector is obtained and the stator β-axis current vector The method includes the following steps:

[0047] Step 31: The observed value of the stator α-axis current in the state observer and the measured stator α-axis current value Subtract to get the current error e;

[0048] Step 32: According to the formula Obtain the stator current observation state quantity derivative of Then for the derivative Integrate to obtain the stator current observation state quantity

[0049] formula:

[0050] A = a 11 0 a ...

specific Embodiment approach 3

[0068] Embodiment 3: This embodiment is a further limitation of the single current sensor vector control method described in Embodiment 1.

[0069] In the step five, the flux linkage angle θ is calculated by using the method of indirect magnetic field orientation:

[0070] θ=∫ω s dt,

[0071] In the above formula:

[0072] ω s = ω r + i sq T r · i sd

[0073] Among them, T r is the rotor time constant.

[0074] The present invention has carried out the experiment to realize the closed-loop control of the system by using a-phase current, the rated voltage of the motor is 380V, the rated power is 1.1kW, the rated speed is 1400rpm, and the given frequency is 20Hz. The experimental results are as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com