Flat-plate-type woofer speaker and electronic device with same

A loudspeaker and flat-panel technology, which is applied in the field of flat-panel woofers and electronic devices using the woofers, can solve the problems of easy saturation of the magnetic circuit system, excess magnet performance, and large magnet size, etc., and achieve high driving force and driving force. Uniform, lighter and thinner structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

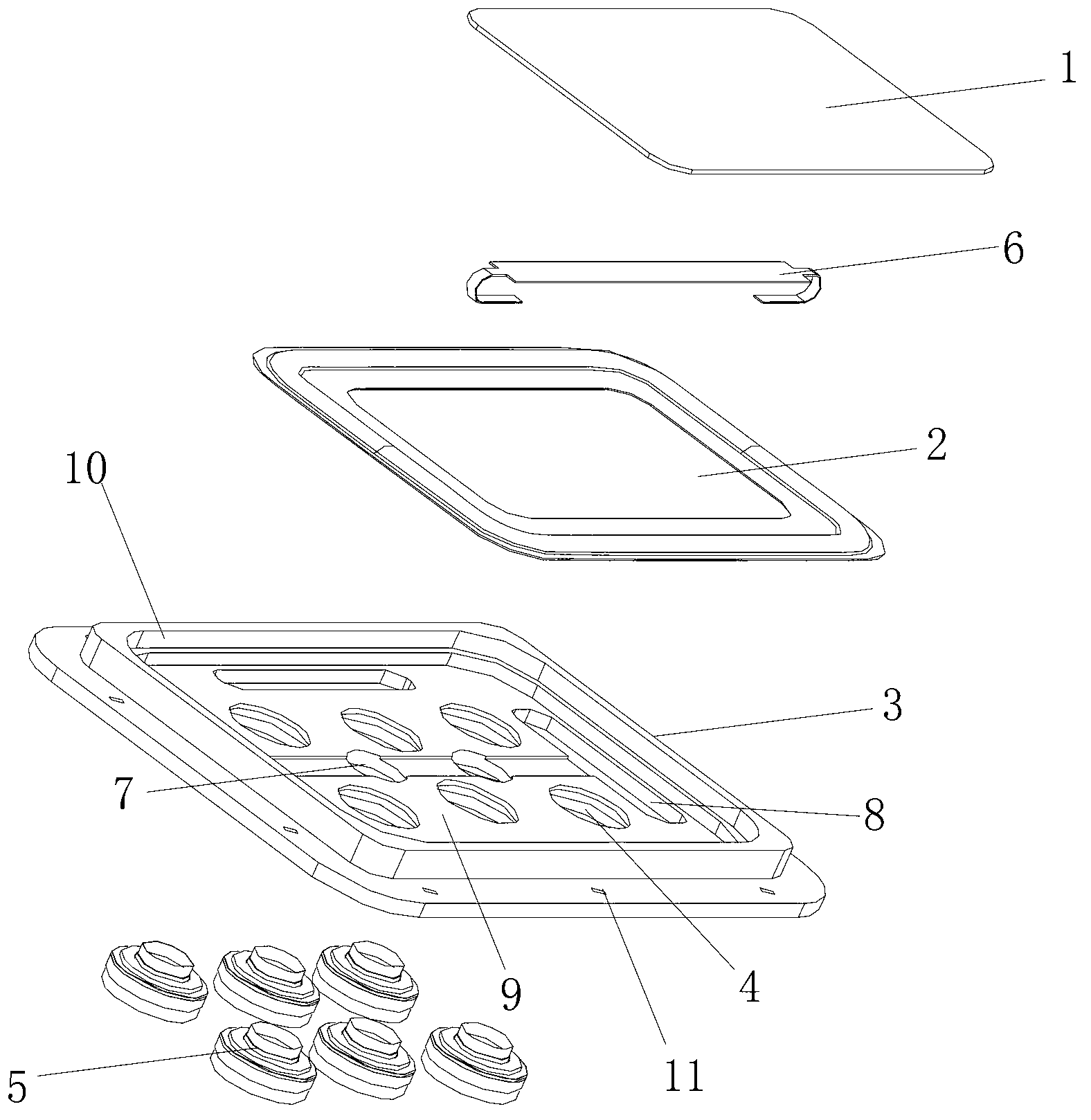

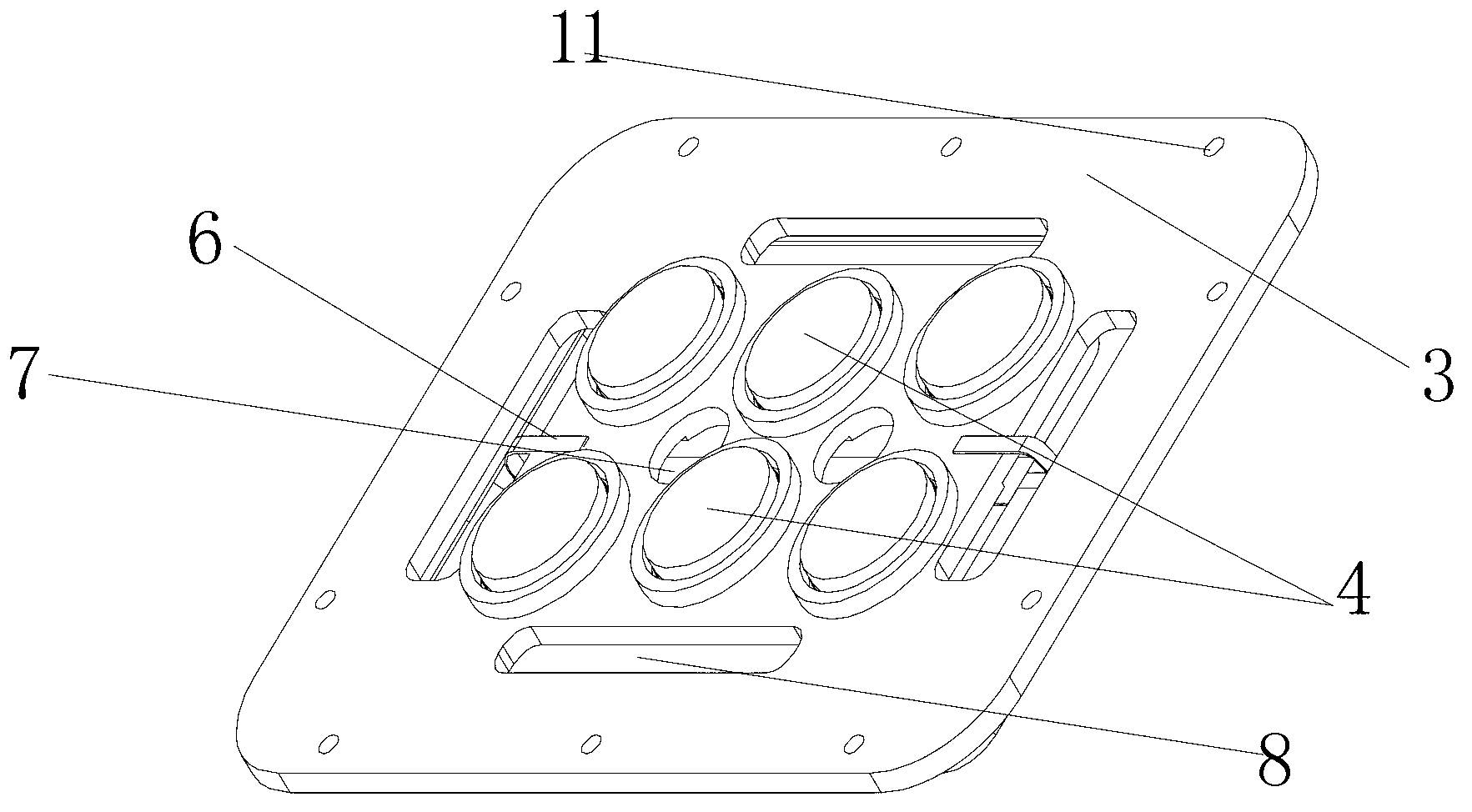

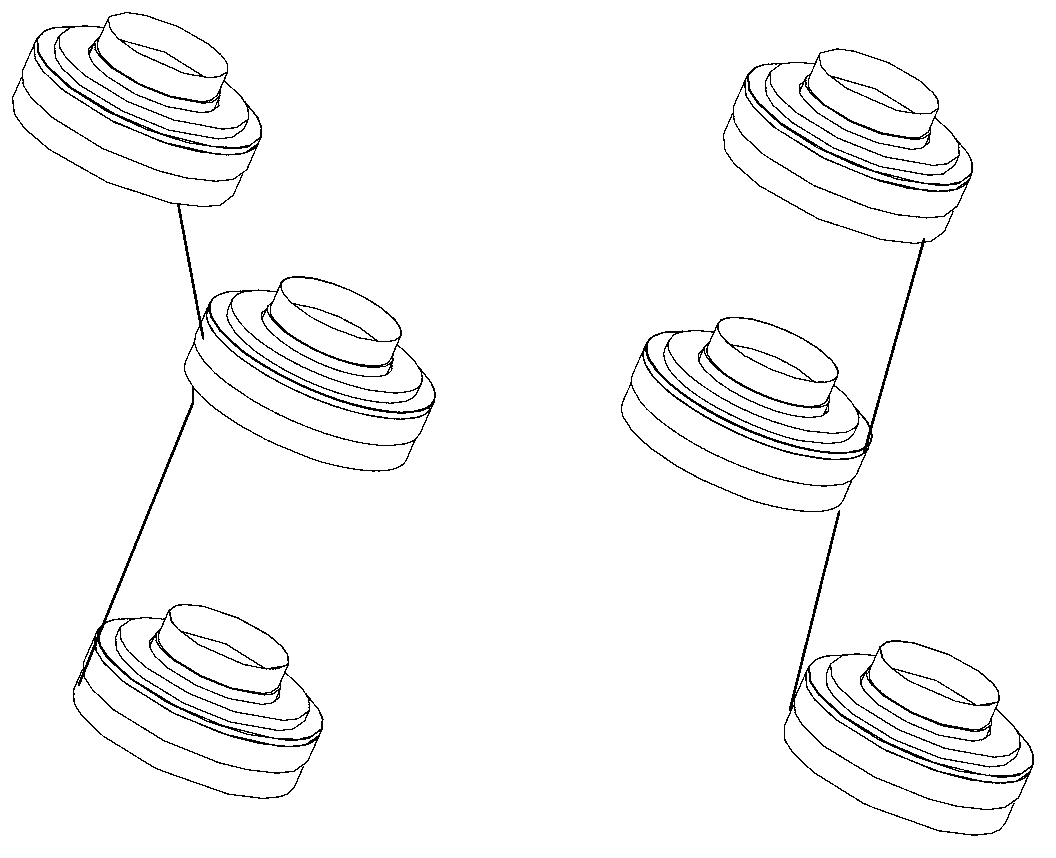

[0042] The woofer requires a larger diaphragm area. In order to provide sufficient drive for the large-area diaphragm on the basis of limiting the size of the voice coil and magnet, the present invention starts from the perspective of dispersing and arranging multiple independent drive units, so that the diaphragm The diaphragm is driven by multiple independent voice coils, and each voice coil corresponds to an independent magnetic circuit unit, so as to realize the miniaturization of the woofer with a more reasonable and effective driving unit layout structure.

[0043] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com