Oil-containing wastewater treatment system

A wastewater treatment system and raw water technology, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of inappropriate precision separation devices, etc., and achieve the purpose of suppressing the reduction of filtration performance, Enhanced stability and reduced installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

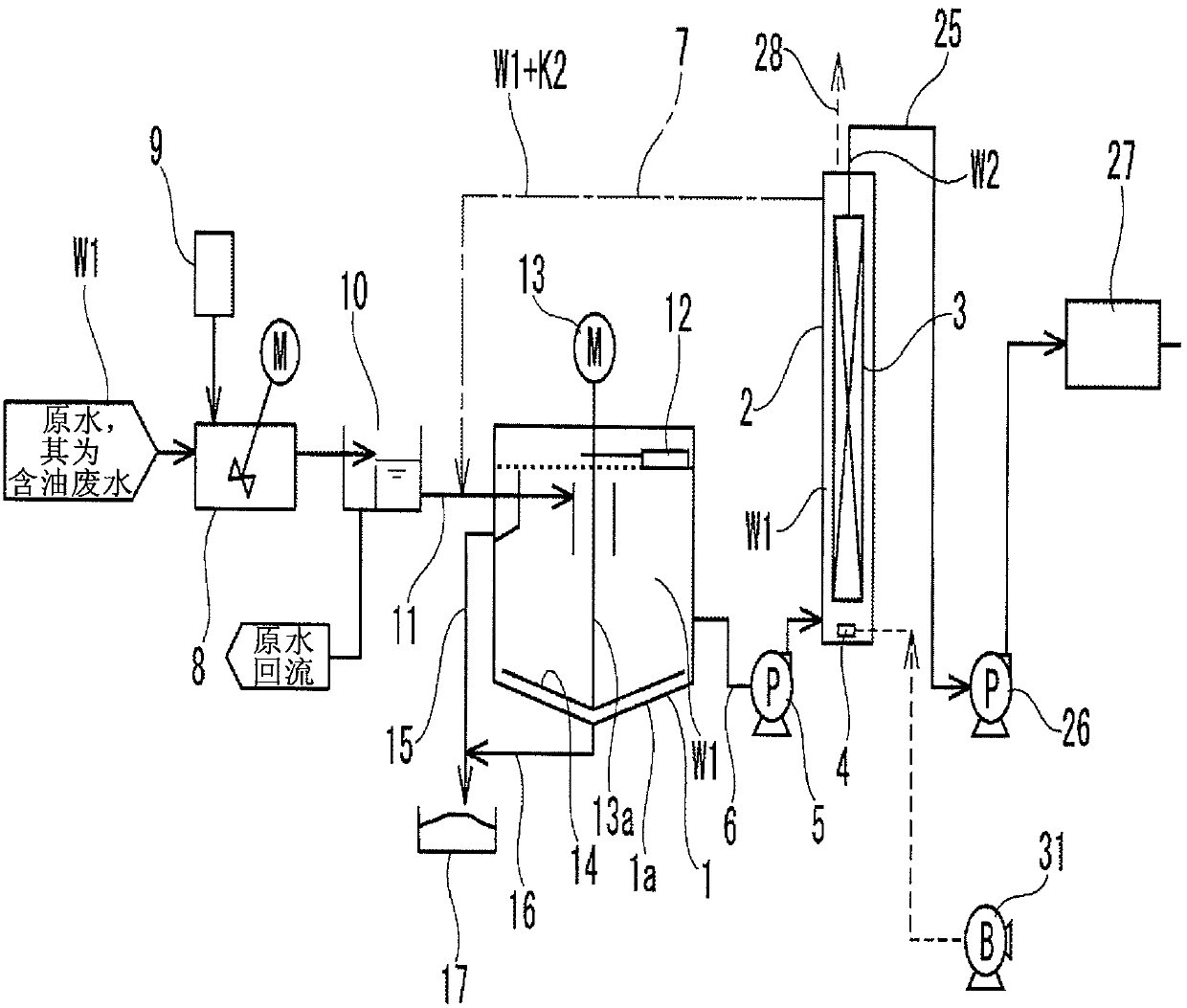

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0034] figure 1 with figure 2 One embodiment of the invention is shown.

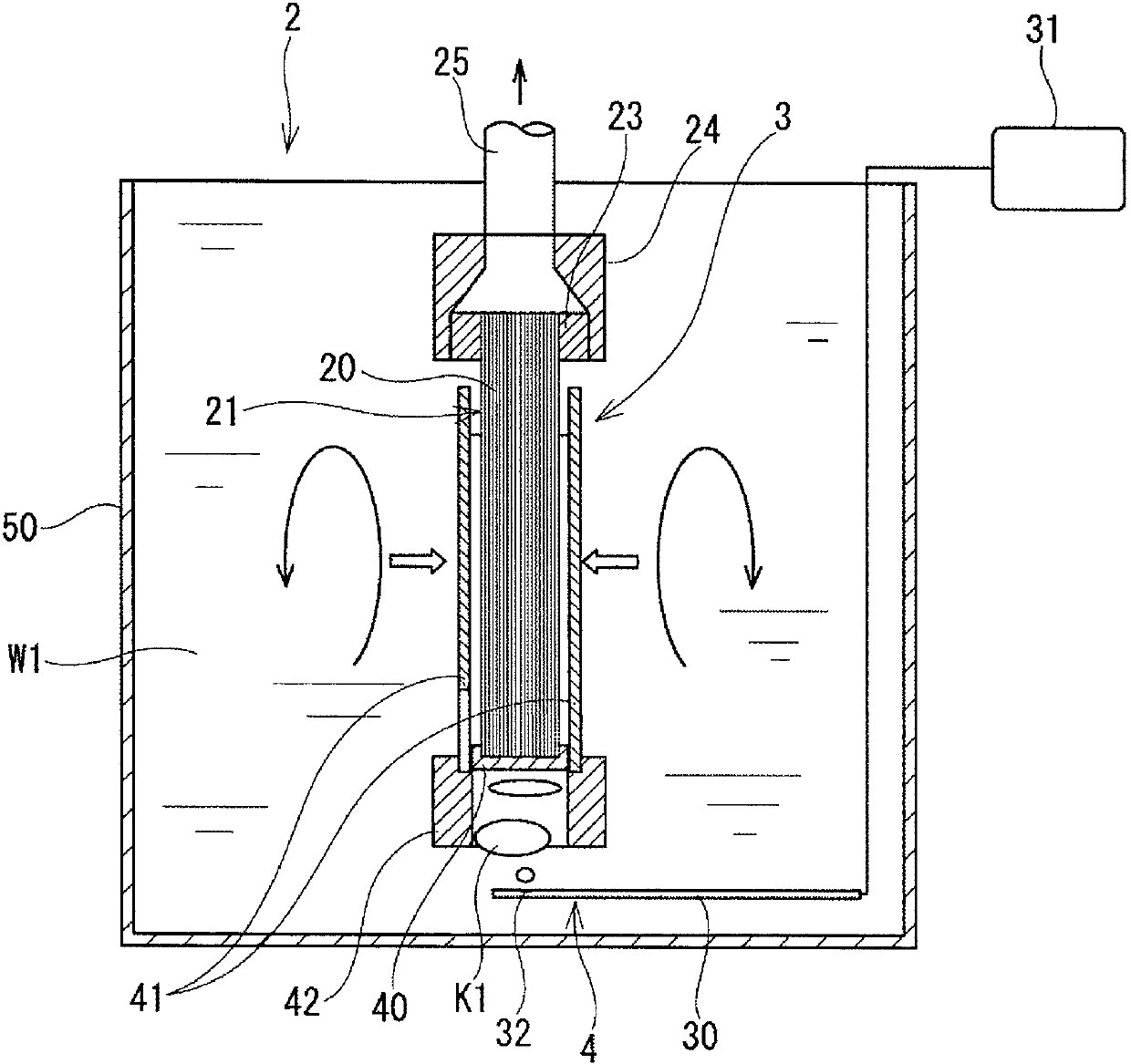

[0035] exist figure 1 In the schematic diagram shown, reference numeral 1 denotes a separation tank which separates impurities by flotation and sedimentation, and reference numeral 2 denotes a membrane filtration tank which filters out impurities with a membrane.

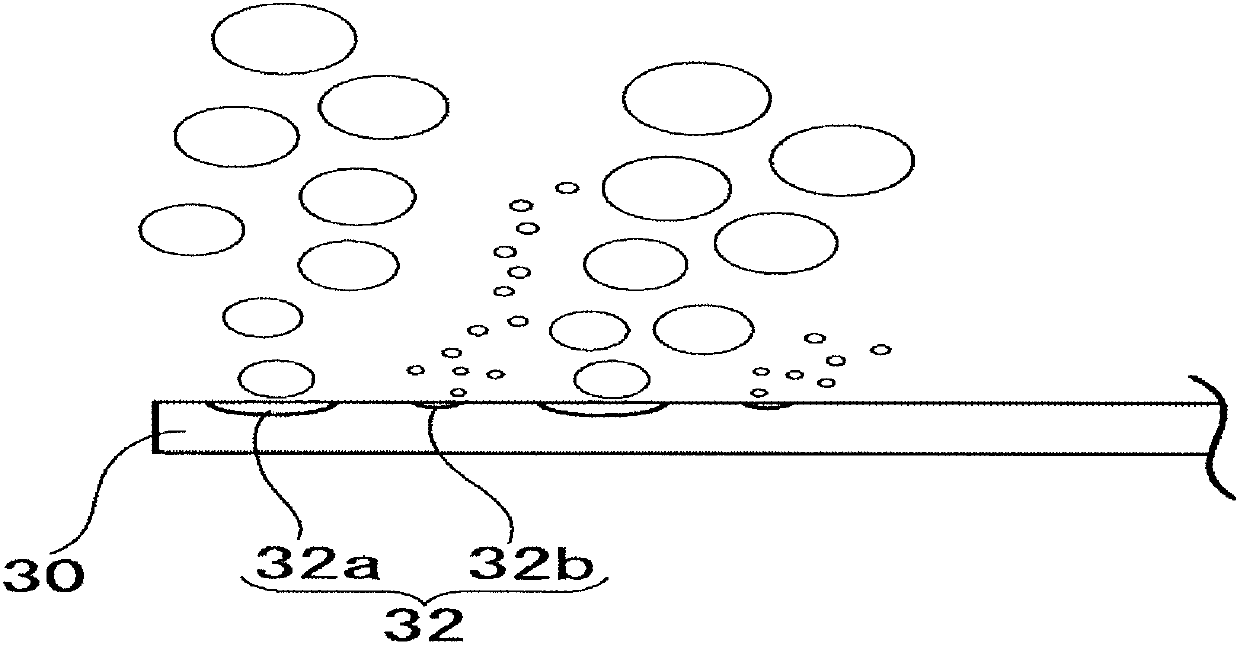

[0036] The membrane filtration tank 2 accommodates a hollow fiber membrane module (membrane separation module) 3 and a bubble generating diffuser 4 arranged below the hollow fiber membrane module 3 .

[0037] The vertical middle area of the separation tank 1 is connected with the lower area of the membrane filtration tank 2 through the supply pipe 6, and a pump 5 is arranged between the two. In addition, a return pipe 7 is provided, which connects the upper area of the membrane filtration tank 2 and the upper area of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com