Cold rolling-drawing method for producing small-sized square flat steel with low-carbon and high-sulfur free-cutting steel

A technology of free-cutting steel and square flat steel, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problem of inability to manufacture qualified small square flat steel billets, so as to avoid heat loss and improve the surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

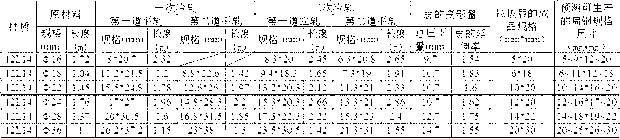

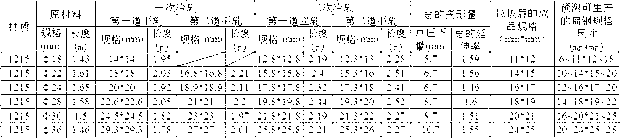

Embodiment 1

[0024] Utilize the cold-rolling-drawing method of producing small square flat steel with low-carbon high-sulfur free-cutting steel of the present invention, the step of making the small flat steel whose cross-sectional size is 5mm*20mm is as follows:

[0025] The first step is material selection. Select the 12L14 steel grade in the ASTM29 / A29M (2005) standard, and the hot-rolled round steel with a diameter of 16mm and a length of 1.72m.

[0026] The second step is to roll the head. Put one end of the φ16 hot-rolled round steel into the flat steel rolling head machine, and use the flat steel rolling head machine to roll it into a flat steel head with a section size of about 4.5mm*19.5mm. The length of the head is about It is 13cm.

[0027] The third step is pickling / shot blasting. For the hot-rolled round steel after rolling, the first pickling / shot blasting is carried out to remove the scale.

[0028] The fourth step is a cold rolling. At normal temperature, the hot-rolle...

Embodiment 2

[0037] Utilize the cold-rolling-drawing method of producing small-sized square flat steel with low-carbon high-sulfur free-cutting steel of the present invention, the step of making the small-sized flat steel that cross-sectional size is 20mm*30mm is as follows:

[0038] The first step is material selection. Select the 12L14 steel grade in the ASTM29 / A29M (2005) standard, and the hot-rolled round steel with a diameter of 36mm and a length of 1m.

[0039] The second step is to roll the head. Put one end of the φ36 hot-rolled round steel into the flat steel rolling head machine, and use the flat steel rolling head machine to roll it into a flat steel head with a section size of about 19.5mm*29.5mm. The length of the head is about It is 13cm.

[0040] The third step is pickling / shot blasting. For the hot-rolled round steel after rolling, the first pickling / shot blasting is carried out to remove the scale.

[0041] The fourth step is a cold rolling. At normal temperature, the...

Embodiment 3

[0050] Utilize the cold-rolling-drawing method of producing small-sized square flat steel with low-carbon high-sulfur free-cutting steel of the present invention, the step of making the small-sized flat steel (approximate square steel) that cross-sectional size is 11mm*12mm is as follows:

[0051] The first step is material selection. Select the 1215 steel type in the ASTM29 / A29M (2005) standard, and the hot-rolled round steel with a diameter of 18mm and a length of 1.43m.

[0052] The second step is to roll the head. Put one end of the φ18 hot-rolled round steel into the flat steel rolling head machine, and use the flat steel rolling head machine to roll it into a flat steel head with a section size of about 10mm*10mm, and the length of the head is about 13cm .

[0053] The third step is pickling / shot blasting. For the hot-rolled round steel after rolling, the first pickling / shot blasting is carried out to remove the scale.

[0054] The fourth step is a cold rolling. At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com