Novel caterpillar section numerical control boring and drilling all-in-one machine

A chain rail link and integrated machine technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of cumbersome chain rail link processing procedures, high material and manufacturing costs, and large accumulative error in clamping, and achieve labor costs. High, low labor cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

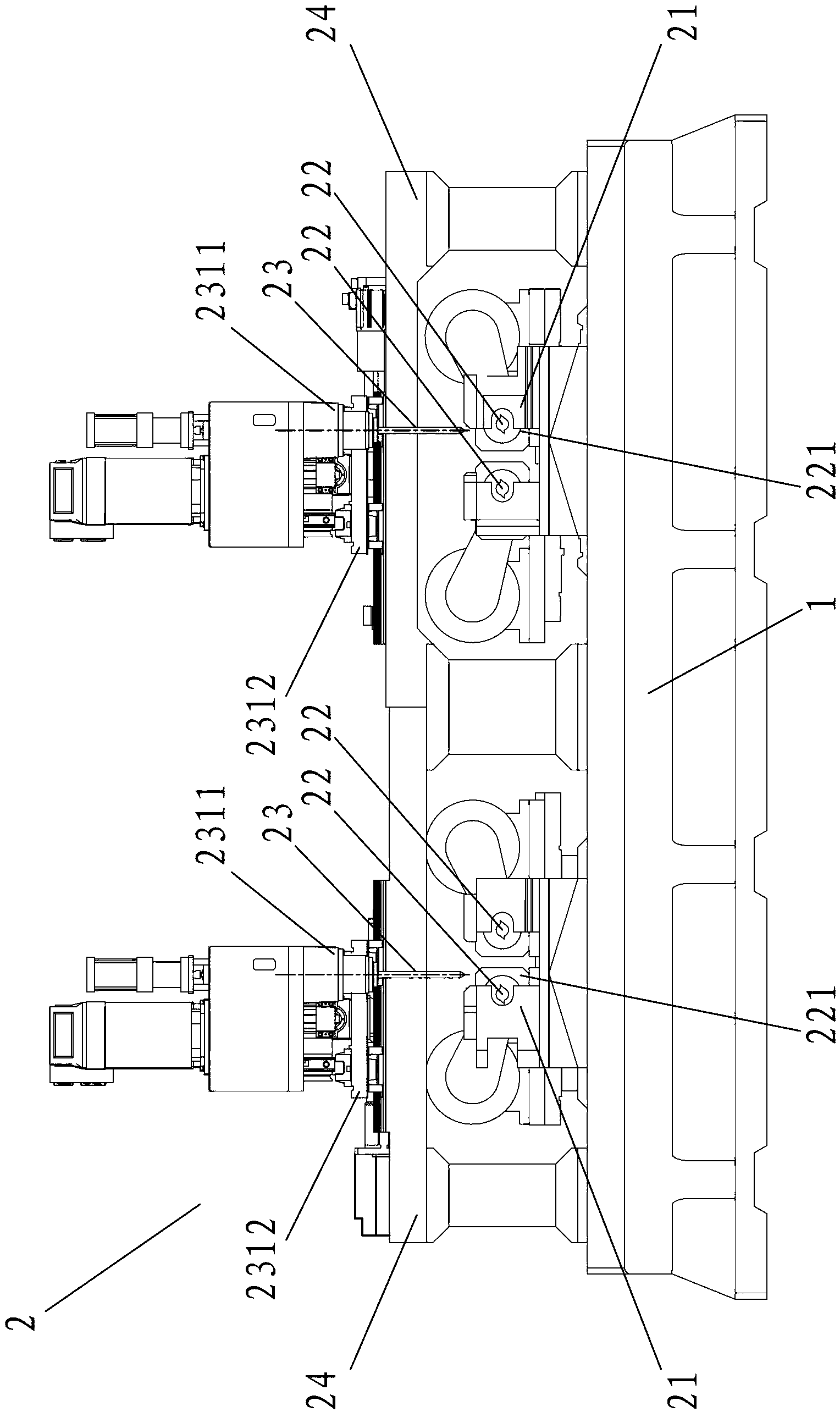

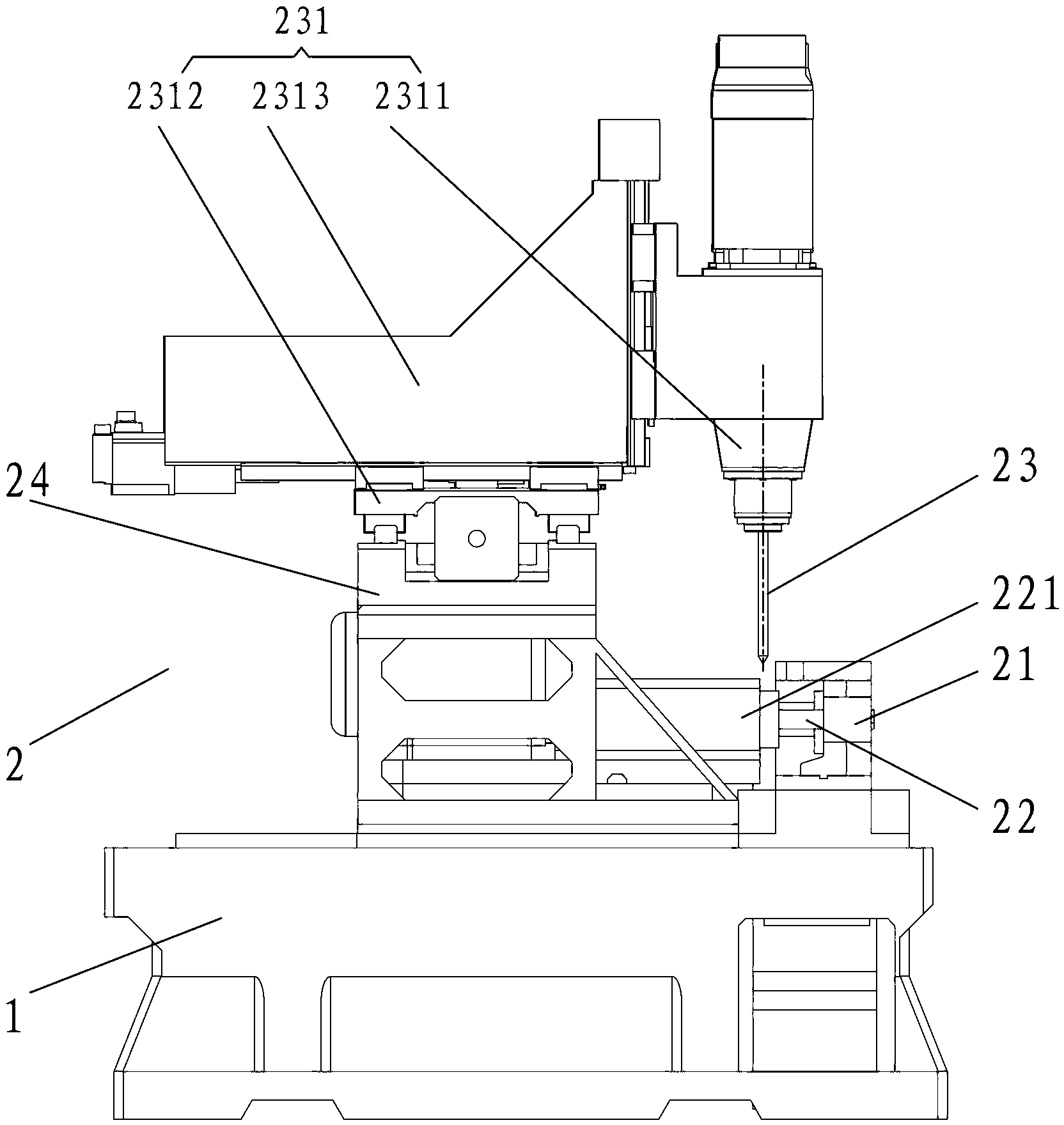

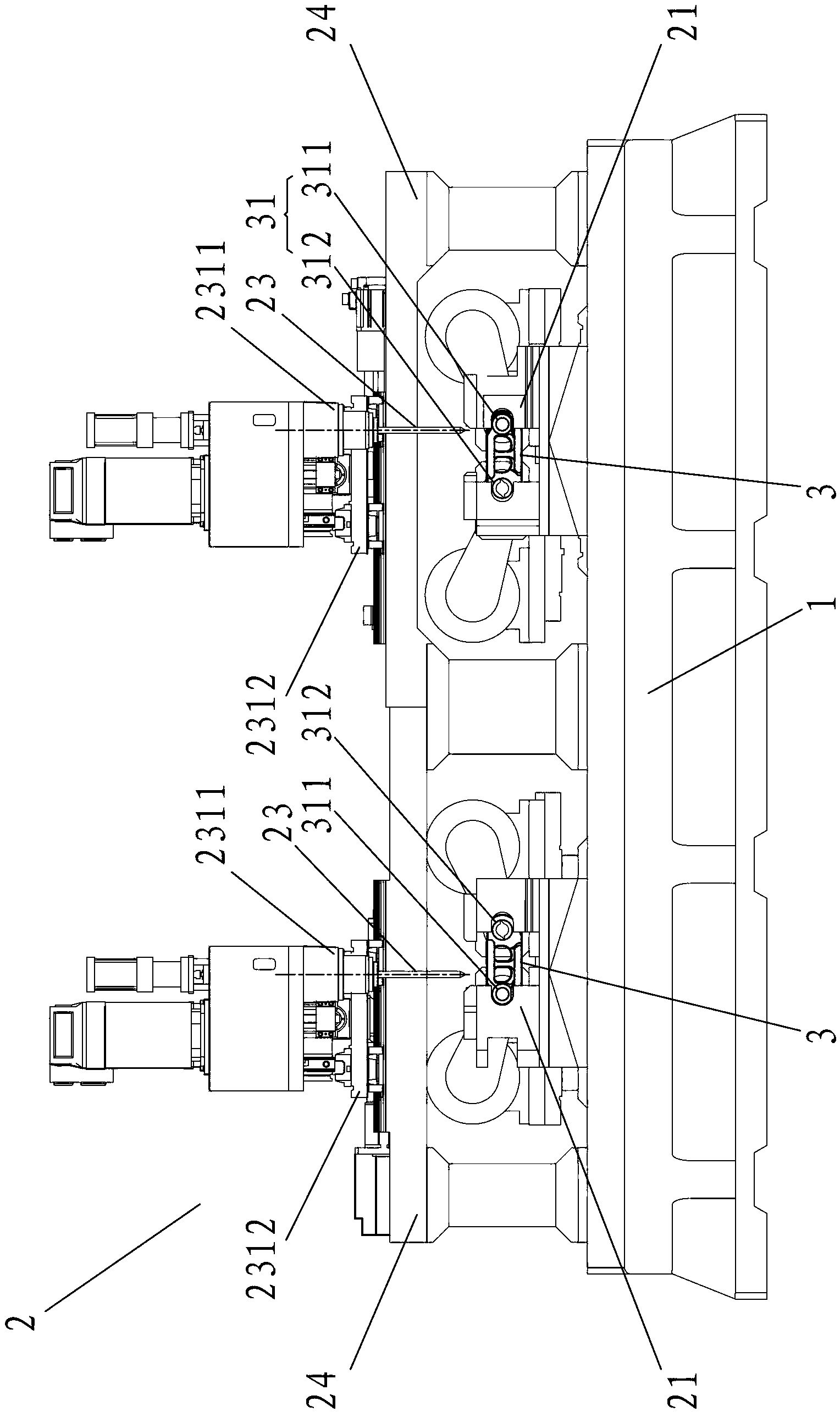

[0032] A new type of chain rail joint CNC boring and drilling machine of the present invention, such as Figure 1-6 As shown, it includes a machine base 1 and a CNC boring and drilling device 2 arranged on the base 1 .

[0033] The CNC boring and drilling device 2 includes a tooling fixture 21, two boring heads 22, and a drill bit 23. The two boring heads 22 correspond to the two pin holes 31 of the processing chain rail section 3 respectively, and the two pin holes 31 are respectively smaller in diameter. The pin shaft hole 311 and the larger pin sleeve hole 312 of the aperture, the drill bit 23 processes the two bolt holes 32 of the chain rail joint 3; That is, the double-head power unit can control the feeding and retraction of the boring head 22, and the double-head power unit 221 is connected with the numerical control controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com