Clean preparation method of 2, 4-dichloro-3, 5-dinitrobenzotrifluoride

A technology of dinitrotrifluorotoluene and dichlorotrifluorotoluene is applied in the field of clean preparation of 2,4-dichloro-3,5-dinitrotrifluorotoluene, and can solve the problems of strong corrosiveness, tail gas pollution, There are many problems such as by-products, so as to achieve the effects of less equipment corrosion, less waste acid discharge, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

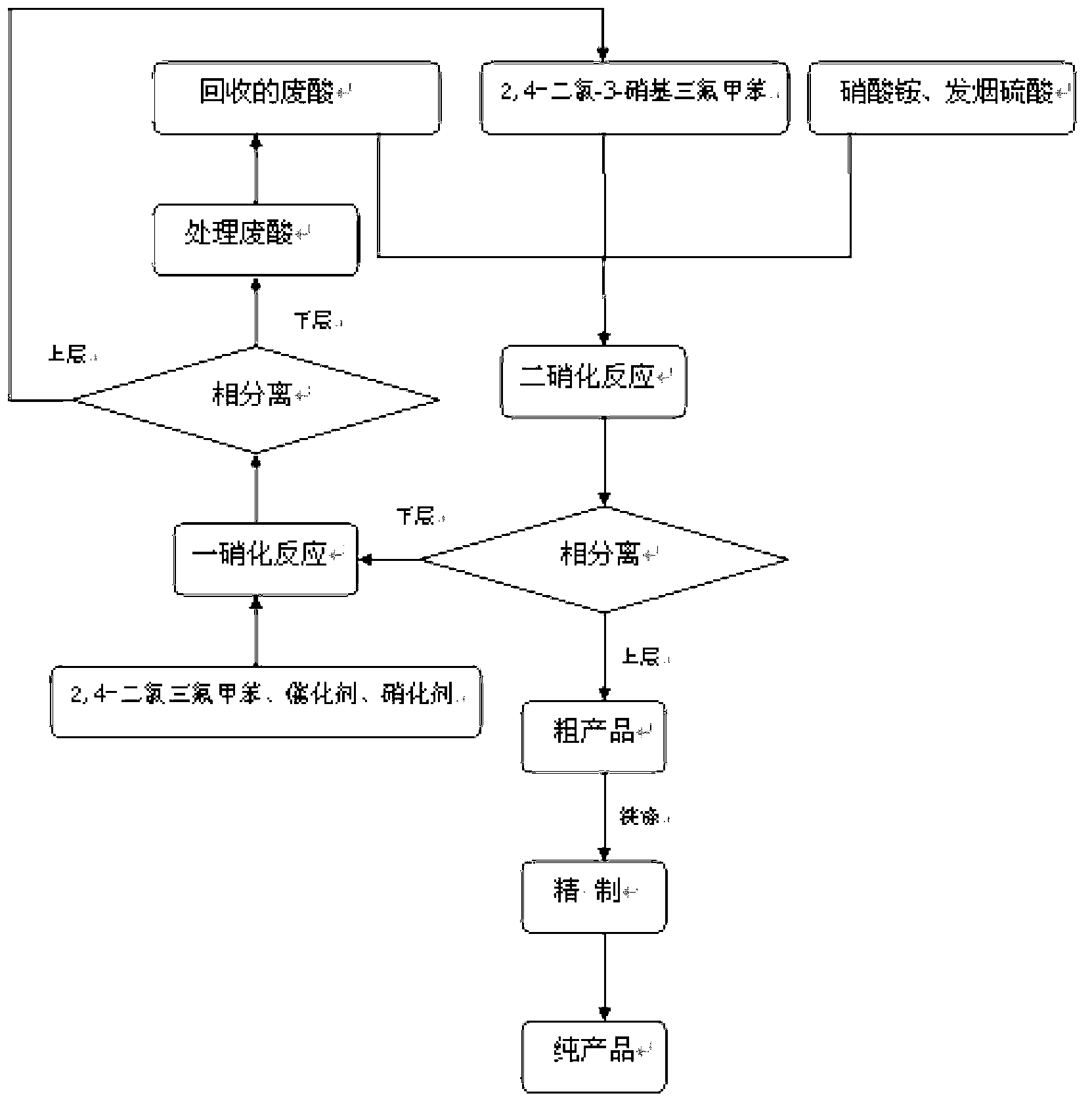

Method used

Image

Examples

Embodiment 1

[0018] In a 500mL four-neck flask, add 35 g of 2,4-dichlorobenzotrifluoride, 30 g of 95% nitric acid, and 45 g of 98% concentrated sulfuric acid in sequence, mix and stir at 40°C for 2 hours, cool and stand still. Separation, the crude product in the upper layer is washed with water, neutralized and dried in vacuum to obtain the pure product 2,4-dichloro-3-nitrobenzotrifluoride, which is used for the next dinitration reaction; the waste acid in the lower layer can be recovered by extracting and drying with cyclohexane For dinitration process.

Embodiment 2

[0020] In a 500mL four-neck flask, add 35 g of 2,4-dichlorobenzotrifluoride, 55 g of 68% nitric acid, and N,N-dimethyl-N-dodecyl-N-sulfonic acid propyl sulfuric acid in sequence Ammonium hydrogen 10 g, mixed and stirred at 50°C for 4 hours, cooled, allowed to stand and phase separated, the crude product in the upper layer was washed with water and dried in vacuum to obtain the pure product 2,4-dichloro-3-nitrotrifluorotoluene, which was used for The next step of the dinitration reaction; the waste acid in the lower layer can be recovered for the dinitration process by extracting and drying with cyclohexane.

Embodiment 3

[0022] In a 500mL four-necked flask, add the mononitrated product 2,4-dichloro-3-nitrobenzotrifluoride 10 g, ammonium nitrate 10 g, and 20% oleum 10 g successively, which were prepared in Example 1, and implement 10 g of the treated waste acid produced in Example 1 was mixed and stirred for 4 hours at 100° C., cooled to 70° C., left to stand for phase separation, and the crude product in the upper layer was cooled to normal temperature for washing, neutralization, refining, and vacuum drying. The pure dinitration product 2,4-dichloro-3,5-dinitrobenzotrifluoride was obtained with a yield of 80%; the semi-waste acid in the lower layer was directly used in the mononitration reaction process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com