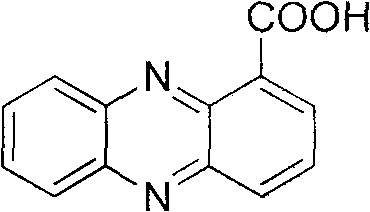

Method for synthesizing phenazine-1-carboxylic acid

A certain amount of shenzimycin, which is applied in the field of synthesis of the microbial-derived pesticide shenzimycin, can solve the problems of harsh conditions, unsuitability for industrial production, and low yield in the second step.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

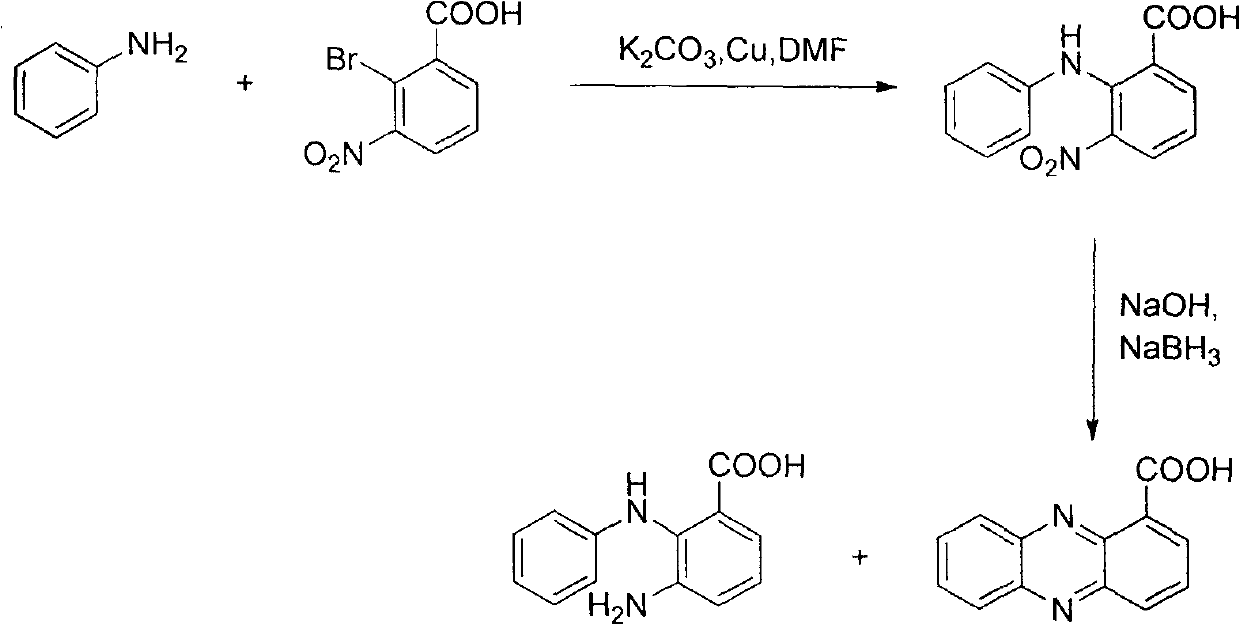

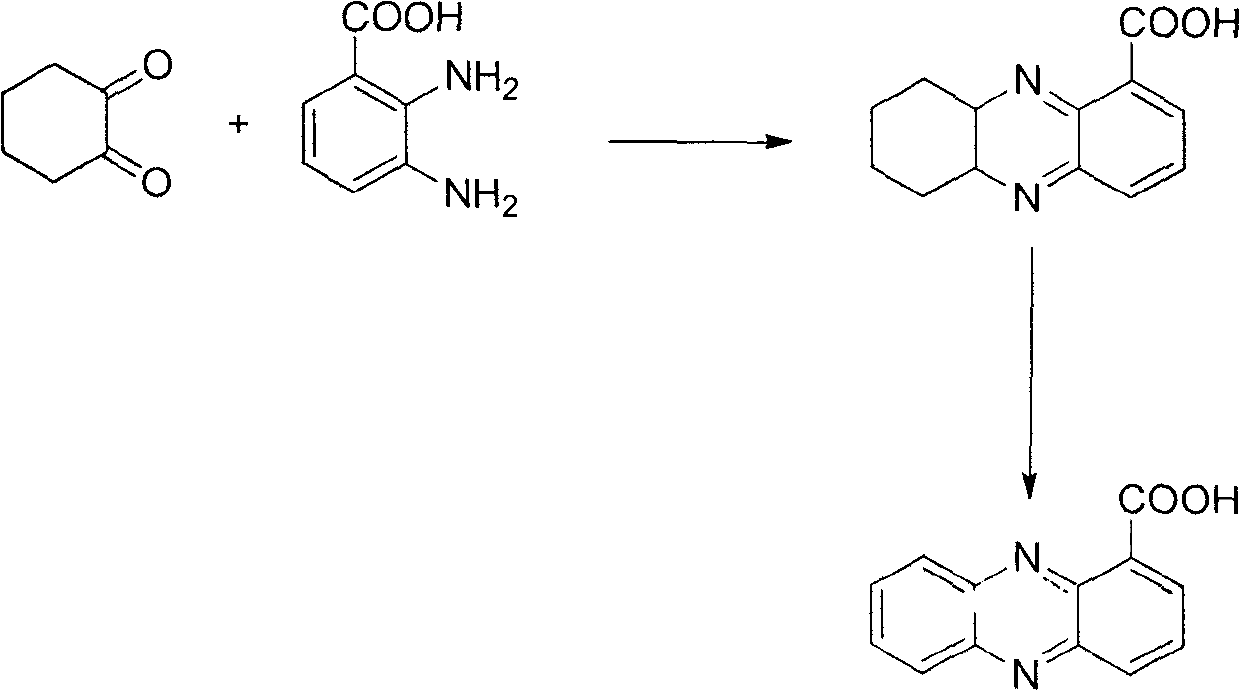

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of 1-methyl-5,10-dihydrophenazine

[0032] In the glove box of nitrogen atmosphere, weigh catechol (1.1g, 10mmol), 2,3-diaminotoluene (1.22g, 10mmol), then pour into mortar, grind and mix well, transfer the mixture to In a 50ml four-neck flask, under magnetic stirring, heat up to 210°C, melt, and keep warm for 35h. Cool to below 100°C, add hot water, stir for about 2 hours, and filter with suction. The filter cake was washed several times with 80°C water and dried to obtain a yellow-green solid. Petroleum ether was recrystallized to obtain 1.26 g of pale yellow-green crystals. Yield 64.2%, melting point 181-182°C.

Embodiment 2

[0033] Embodiment 2: the preparation of 1-methyl-5,10-dihydrophenazine

[0034] In the glove box of nitrogen atmosphere, take catechol (1.32g, 12mmol), 2,3-diaminotoluene (1.22g, 10mmol), then pour into mortar, fully grind and mix, and transfer the mixture to In a 50ml four-neck flask, under magnetic stirring, heat up to 190°C, melt, and keep warm for 40h. Cool to below 100°C, add hot water, stir for about 2 hours, and filter with suction. The filter cake was washed several times with 80°C water and dried to obtain a yellow-green solid. Petroleum ether was recrystallized to obtain 1.43 g of light yellow-green crystals. Yield 73.1%, melting point 181-182°C.

Embodiment 3

[0035] Embodiment 3: the preparation of 1-methyl-5,10-dihydrophenazine

[0036] In a glove box under a nitrogen atmosphere, weigh catechol (1.1g, 10mmol), 2,3-diaminotoluene (1.46g, 12mmol), pour into a mortar, grind and mix well, and transfer the mixture to In a 50ml four-neck flask, under magnetic stirring, heat up to 150°C, melt, and keep warm for 50h. Cool to below 100°C, add hot water, stir for about 2 hours, and filter with suction. The filter cake was washed several times with 80°C water and dried to obtain a yellow-green solid. Petroleum ether was recrystallized to obtain 1.31 g of pale yellow-green crystals, with a yield of 66.9% and a melting point of 181-182°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com