Yarn and manufacturing technique

A manufacturing process and yarn technology, applied in the field of functional yarns and manufacturing processes, can solve the problems of high production cost and complex manufacturing process of composite yarns, achieve improved visual effects, good dustproof and antistatic effects, The effect of a good feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

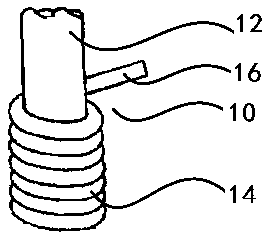

[0021] as attached figure 1 As shown, the present embodiment provides a yarn with conductive function and good air permeability. The yarn 10 includes: a yarn core 12, the yarn core is a conductive fiber, and the conductive fiber is electroless copper-plated on the surface. Polyester fiber; the cladding layer 14 includes dumbbell-shaped polyester fiber 16, and the dumbbell-shaped polyester fiber is wrapped on the yarn core clockwise or counterclockwise. Wherein, the cross-shaped polyester fiber accounts for 80% of the total weight of the yarn, and the conductive fiber accounts for 20% of the total weight of the yarn. The conductive fiber is prepared by the following electroless plating method: first, soak the polyester fiber in a chemical activation solution for 15 minutes for activation treatment, the activation temperature is 30-35°C, and the chemical activation solution is composed of sodium borohydride, 2 , 2`-bipyridine, potassium tellurite, nickel sulfate, sodium hydroxi...

Embodiment 2

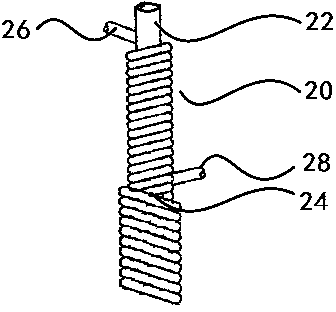

[0023] as attached figure 2 As shown, the present embodiment provides a yarn with conductive function and good air permeability. The yarn 20 includes: a yarn core 22, the yarn core is a conductive fiber, and the conductive fiber is electroless copper-plated on the surface. Polyester fiber; cladding layer 24, comprises cross type polyester fiber 26, and described cross type polyester fiber 26 is wrapped on the described yarn core along clockwise or anticlockwise; Also comprises second fiber 28 in addition, so The second fiber 28 is bamboo charcoal fiber, and the bamboo charcoal fiber is wrapped on the cladding layer formed by the first fiber along a second direction, and the first direction is opposite to the second direction. Wherein, the first fiber accounts for 70% of the total weight of the yarn, the conductive fiber accounts for 15% of the total mass of the yarn, and the bamboo charcoal fiber accounts for 15% of the total mass of the yarn. The conductive fiber is prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com