Adjustable support frame used for drilling hole upward and vertically

A support frame and drilling rig technology, which is applied to drilling equipment, earthwork drilling, support devices, etc., can solve the problems that the verticality is difficult to meet the design requirements, the verticality is not easy to be guaranteed, and the stroke cannot be too long, so as to protect the health, Conducive to safe construction and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

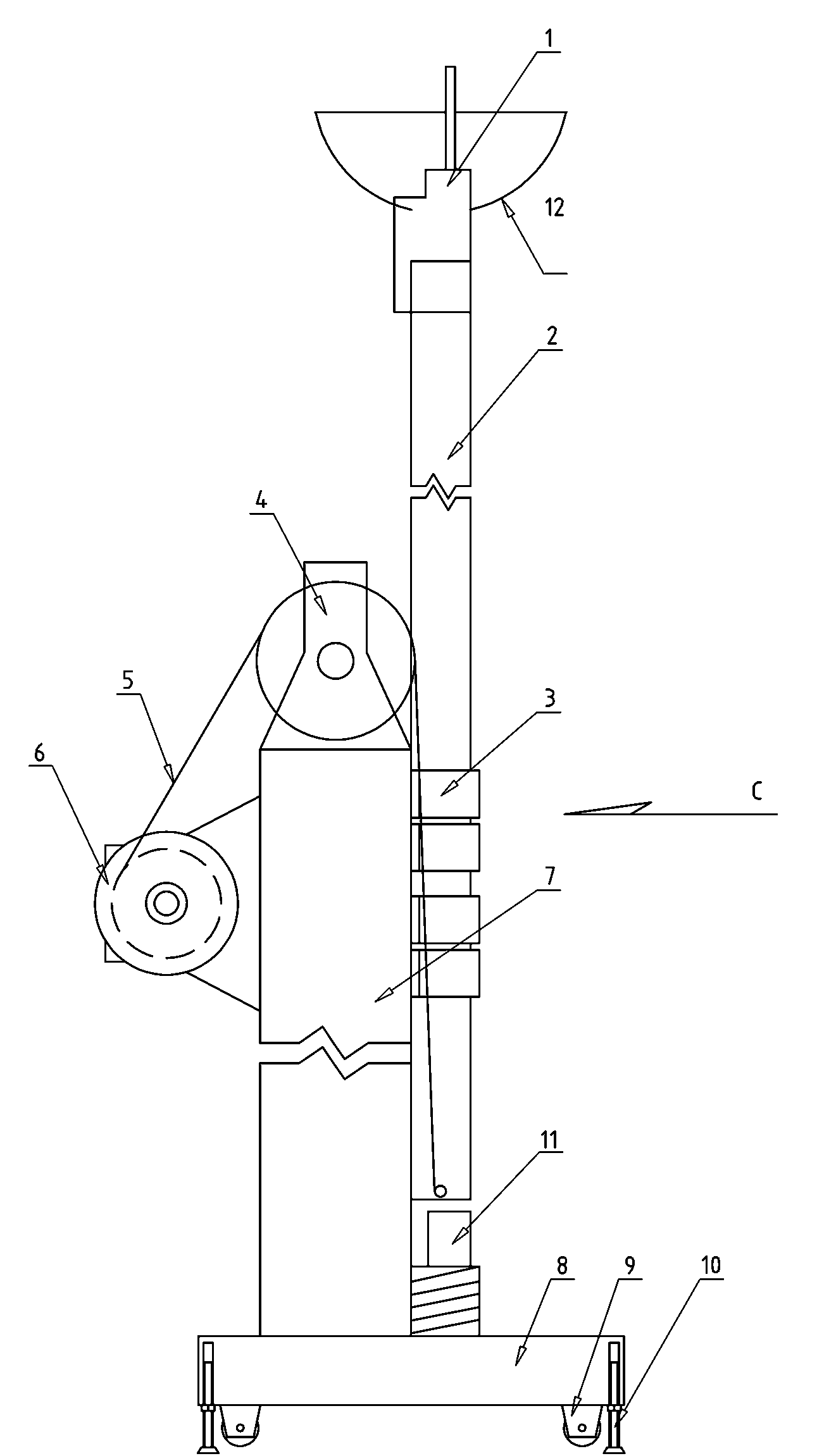

[0035] Such as figure 1 Among them, an adjustable support frame for drilling vertically upwards, including a base 8, the base in this example adopts a combined structure of a roller (9) and a base lifting device (10), wherein the roller (9) is convenient for the movement of the present invention, The base lifting device (10) is convenient for adjusting the levelness of the base 8 and provides good support. Usually, the base lifting device (10) adopts a screw structure. Base also can be the structure of tripod.

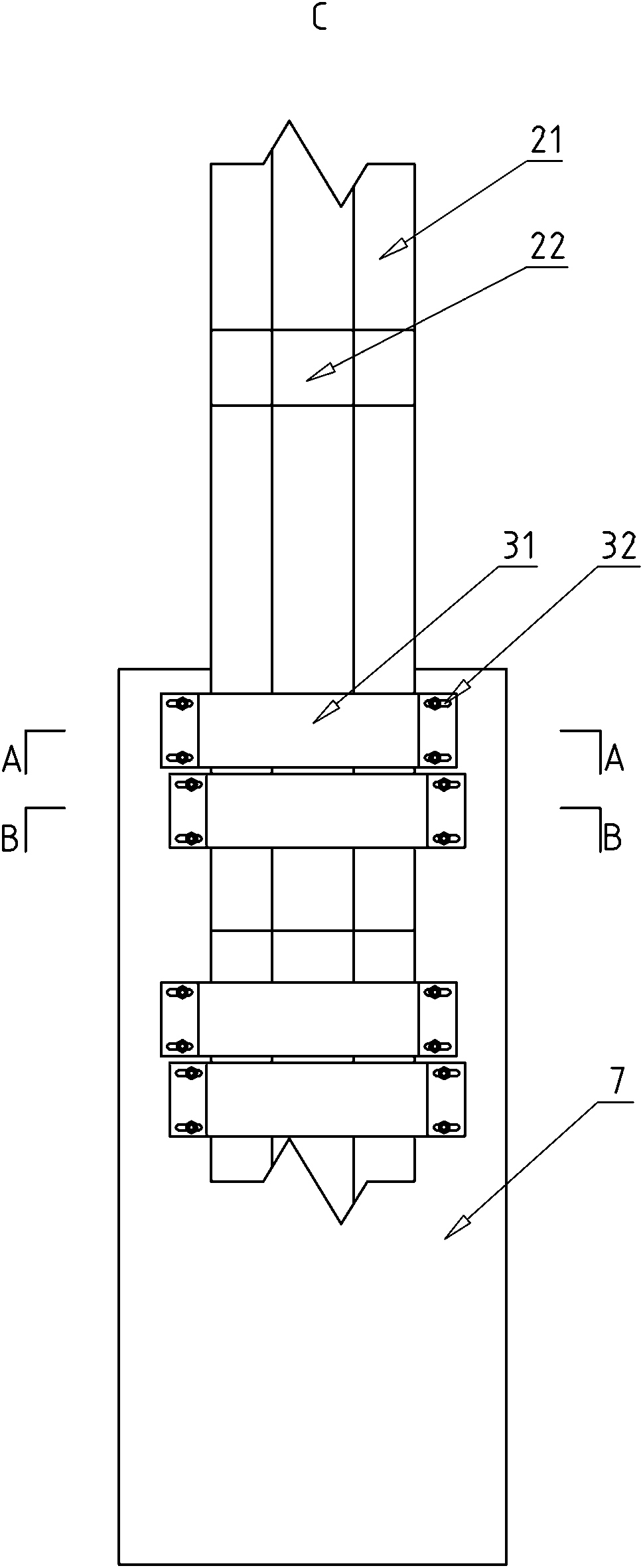

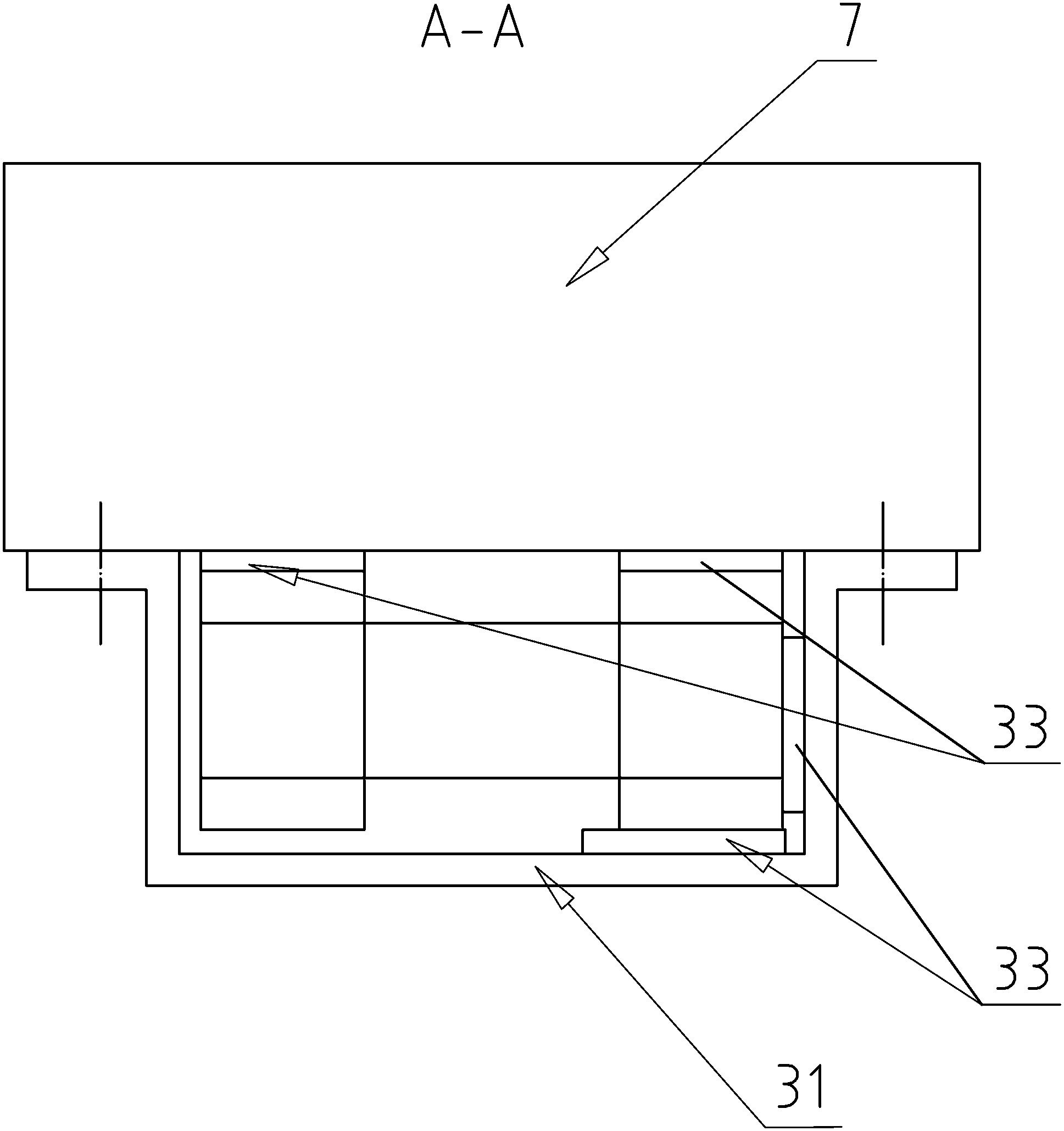

[0036] The base 8 is provided with a column 7, and the push rod 2 is connected with the slide rail 3 and the column 7 in a manner that can slide along the axis of the column 7. Hoisting device 6, the rope 5 of hoisting device 6 is connected with the bottom of push rod 2 through pulley device 4. With this structure, the construction personnel rotate the winch device 6, and the ejector rod 2 can be moved upward through the pulley device 4, and the trajectory is a strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com