Refrigeration system for mine cooling

A refrigeration system and mine technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of reducing the refrigeration coefficient of refrigerators, large losses, and difficulty in cold delivery, and achieve low mine drainage temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

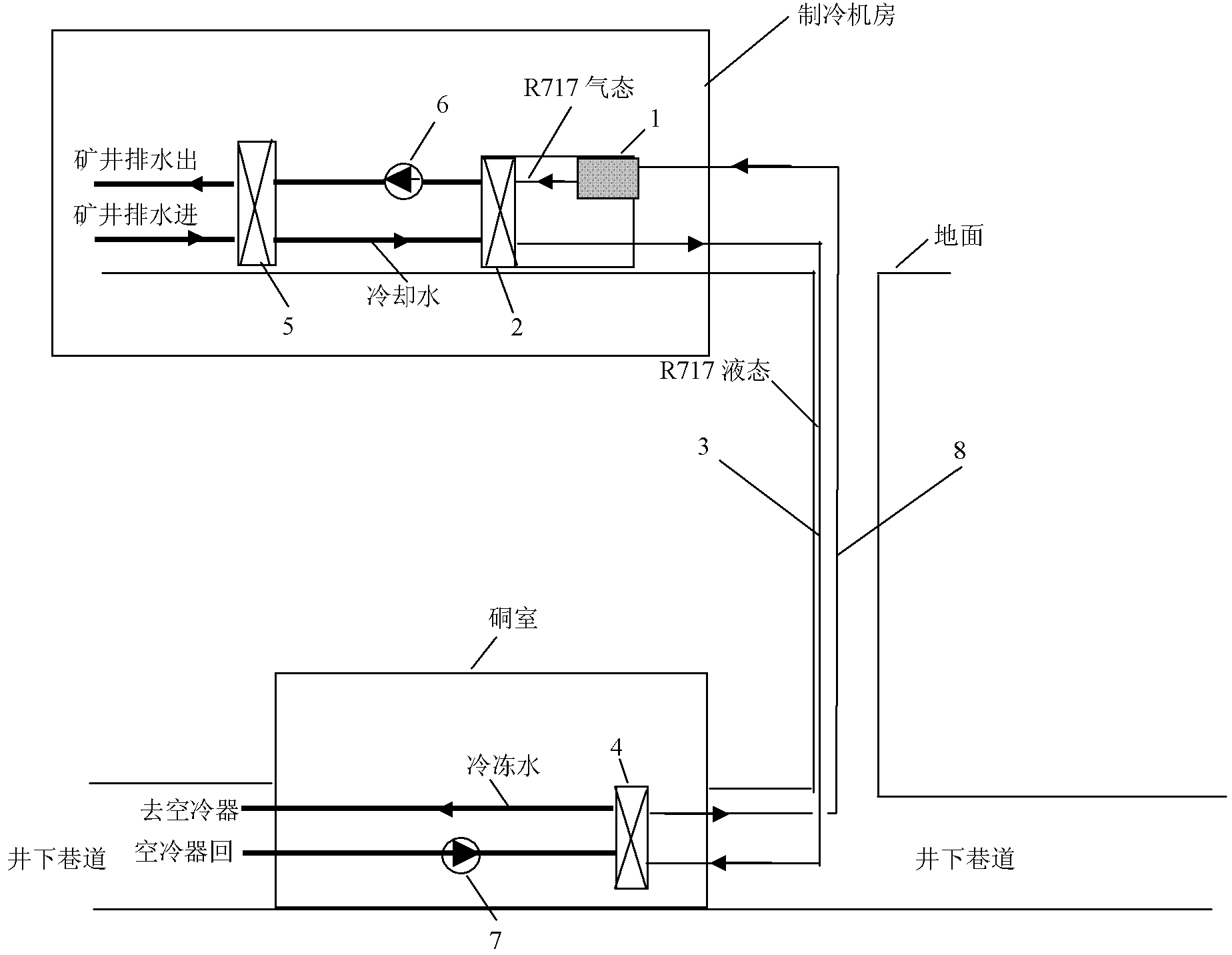

[0032] The refrigerating system provided by the present invention can simultaneously realize surface refrigerating and efficiently transport cooling underground.

[0033] The technical scheme that the present invention takes and its working principle:

[0034] A refrigeration system for mine cooling, the main equipment (except the evaporator) is placed on the well, and a chamber is set near the shaft of the return air shaft to place the evaporator and underground chilled water preparation and circulation equipment; the refrigeration adopts a vapor compression refrigeration cycle system, and the refrigeration Agent R717, evaporator and condenser all adopt plate heat exchanger, the compressor adopts screw type, and the throttling element is a slender tube; mine drainage is used to cool the cooling water.

[0035] Its working principle is: Refrigerant R717 is compressed in the Inoue compressor to become a high-temperature and high-pressure gaseous refrigerant, enters the Inoue co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com