Detonation engine

A technology of detonation engine and movable plug, which is applied to mechanical equipment, intermittent injection devices, etc., can solve the problems of unreachable detonation engine, and achieve the effects of reducing the time used, high thermal cycle efficiency, and increased rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

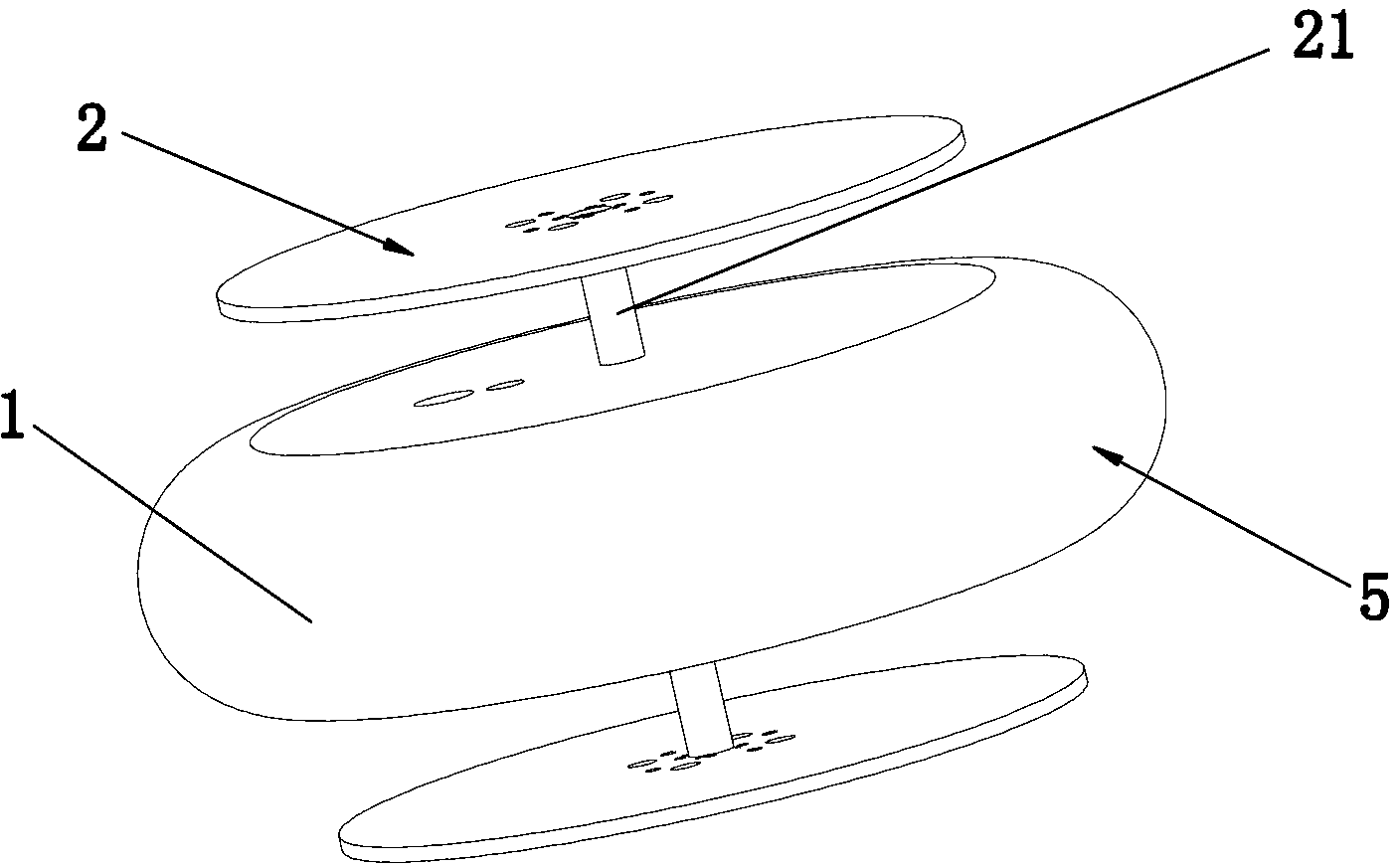

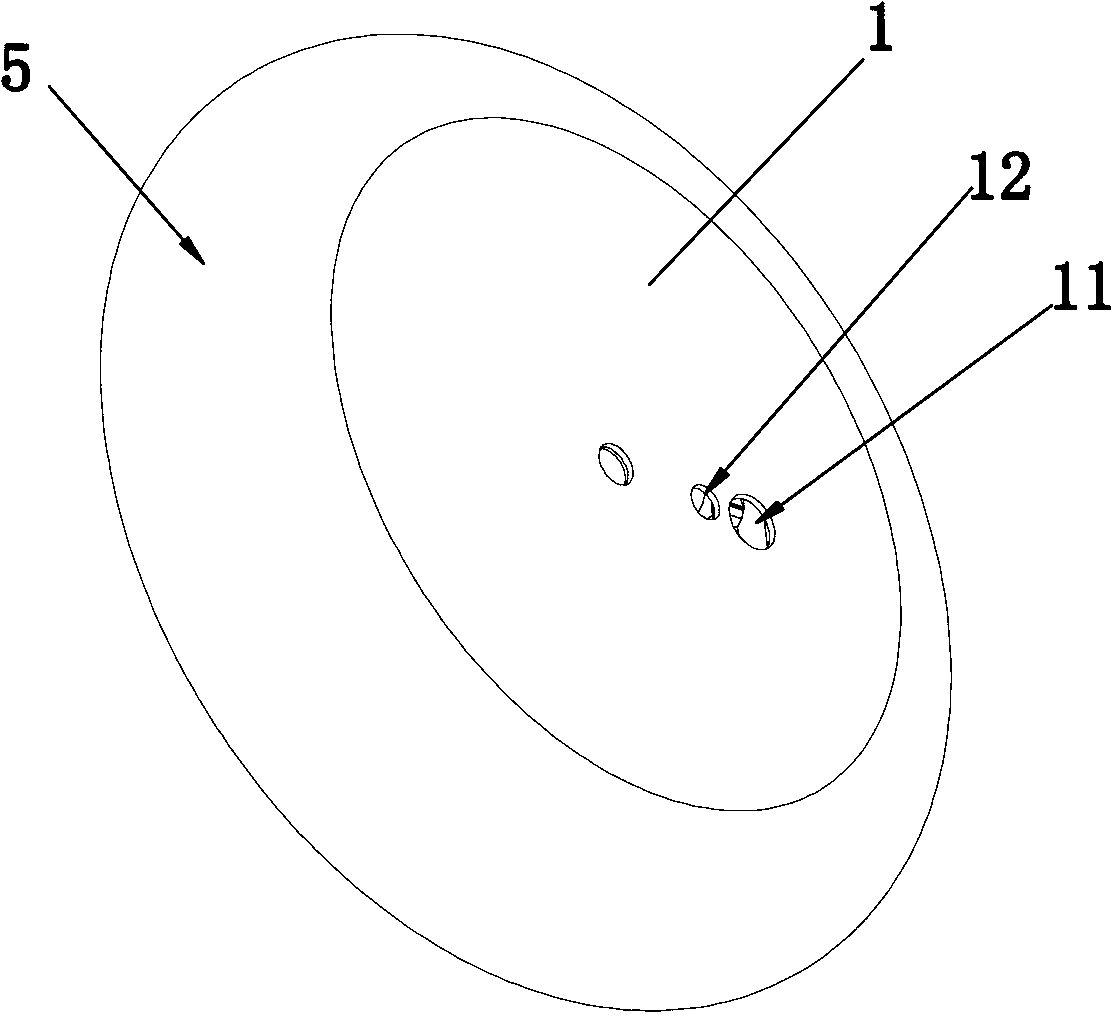

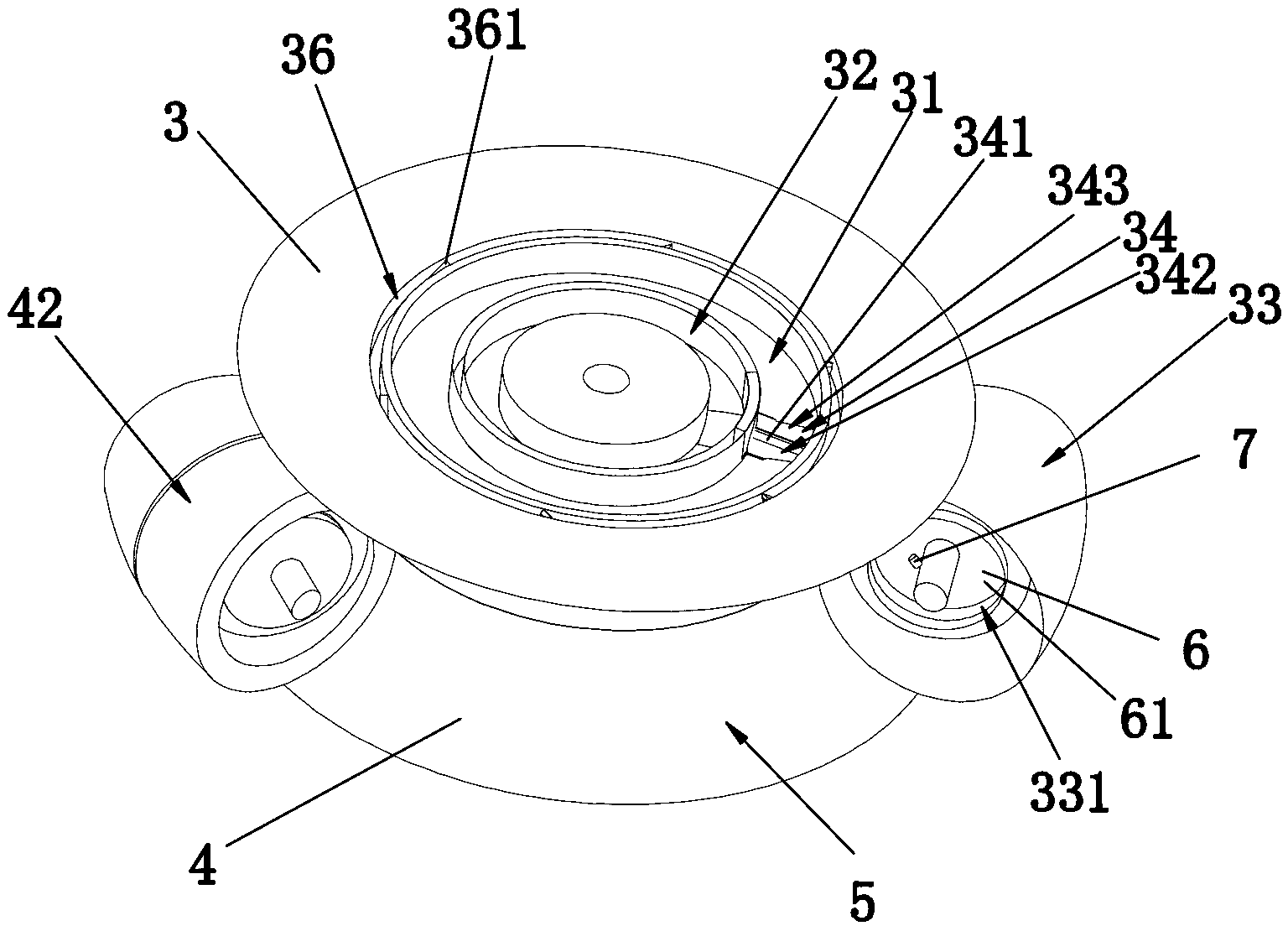

[0043] like Figure 1-Figure 14 As shown, the embodiment of the present invention is specifically a detonation engine, including a housing 1 and a power output device 2, and the housing 1 is coaxially provided with an intake rotary disk 3 and an air outlet rotary disk 4, and the intake rotary disk 3 is away from the air outlet rotary disk One side of 4 is provided with a combustible gas chamber 31 and an oxygen chamber 32, and the side of the air outlet turntable 4 facing away from the intake turntable 3 is provided with an air outlet chamber 41, and the radially outer walls of the inlet turntable 3 and the outlet turntable 4 are in contact with the shell 1. An annular channel 5 is formed between the inner side walls, and the radially outer walls of the intake rotary disk 3 and the air outlet rotary disk 4 are respectively provided with an air intake movable plug 33 and an air outlet movable plug 42 that can slide along the annular channel, and an air intake movable plug 33 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com