Piezoelectric type rotating speed meter

A piezoelectric and rotational speed technology, applied in the direction of steering induction equipment, etc., can solve the problems of not being able to paste piezoelectric ceramics, the influence of input signals, and difficult processing, etc., and achieve the effects of low cost, improved signal-to-noise ratio, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

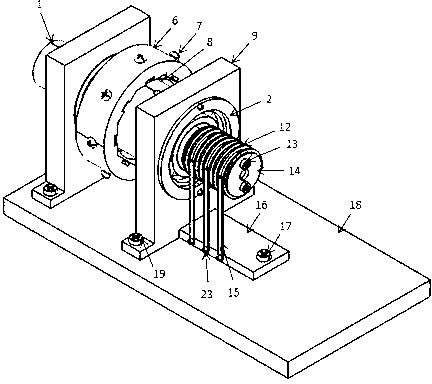

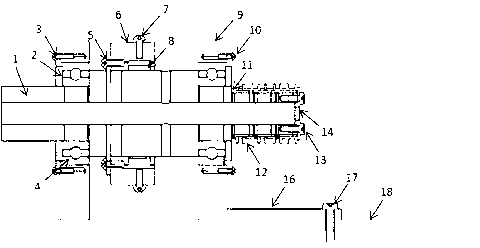

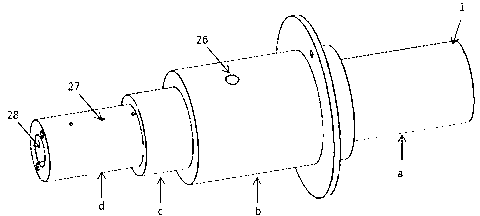

[0033] Please refer to Figure 1 to Figure 5 and combine Figure 6 to Figure 7 shown. The piezoelectric tachometer of the present invention includes a base 18, a rotating shaft structure, a piezoelectric vibrating ring structure and a brush structure. The rotating shaft structure is fixed on the base 18 , the piezoelectric vibrating ring structure is installed on the stepped shaft 1 , and the brush structure is fixed on the stepped shaft 1 and the base 18 . The rotating shaft structure includes a stepped shaft 1 divided into four sections, a support plate 9, a bearing 4 and a bearing cover 2. The support plate 9 and the base 18 are fixedly connected by the fifth connecting screw 19, and the bearing 4 is connected by the first connecting screw through the bearing cover 2. 3 and the third connecting screw 10 are fixed on the support plate 9, and the first section a and the third section c of the stepped shaft are fixedly connected to the two bearings 4 respectively.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com