Device and method for testing performance of blue light-emitting diode (LED) excitation fluorescent powder

A technology of LED light source and phosphor powder, applied in the field of phosphor powder, can solve the problems of not considering the influence of the excitation efficiency of the phosphor powder of the LED light source, the test deviation of the luminescence performance of the phosphor powder, the difference of the excitation spectrum of the LED, etc., so as to improve the ability to obtain light , Improve the utilization of light energy, the effect of stable light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

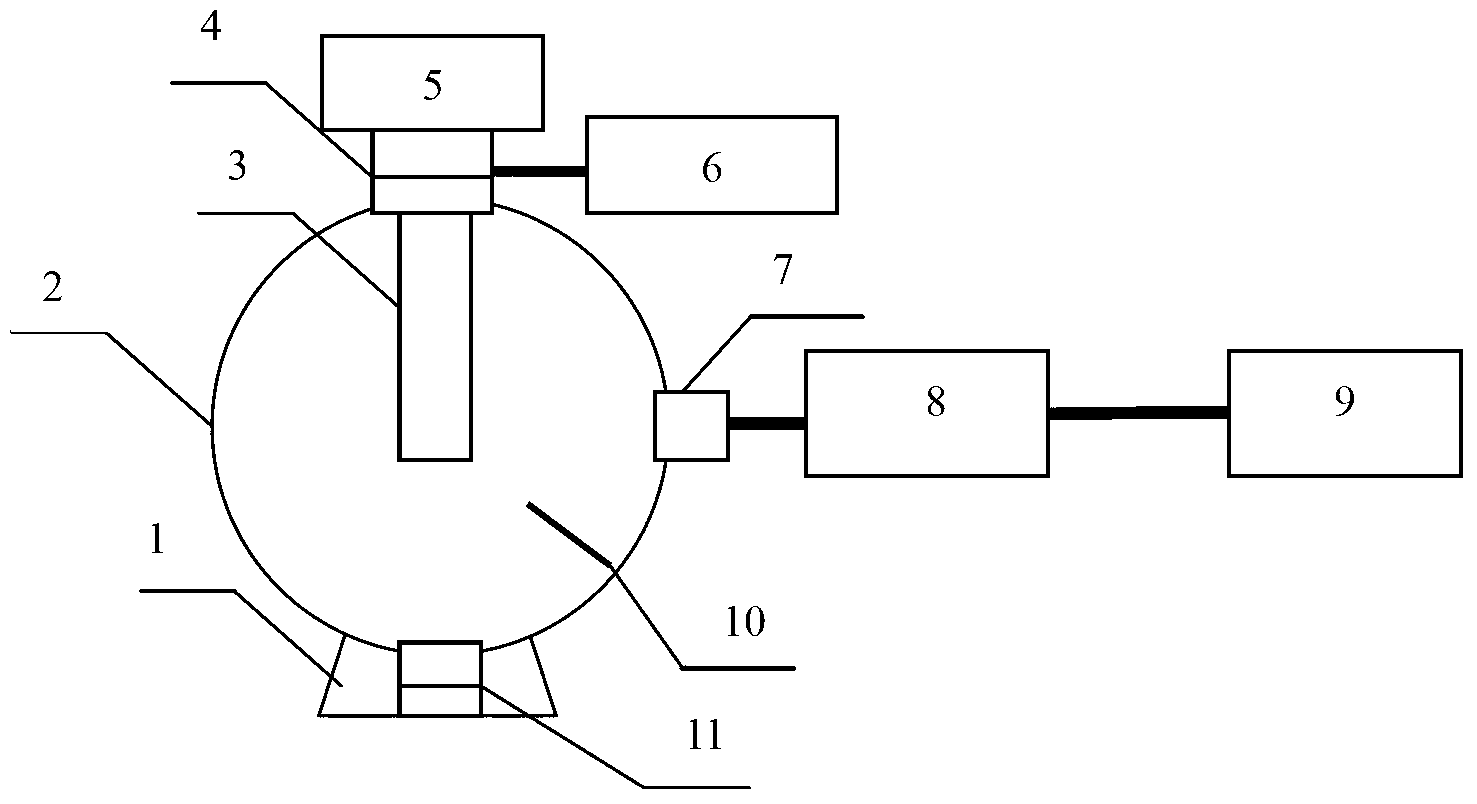

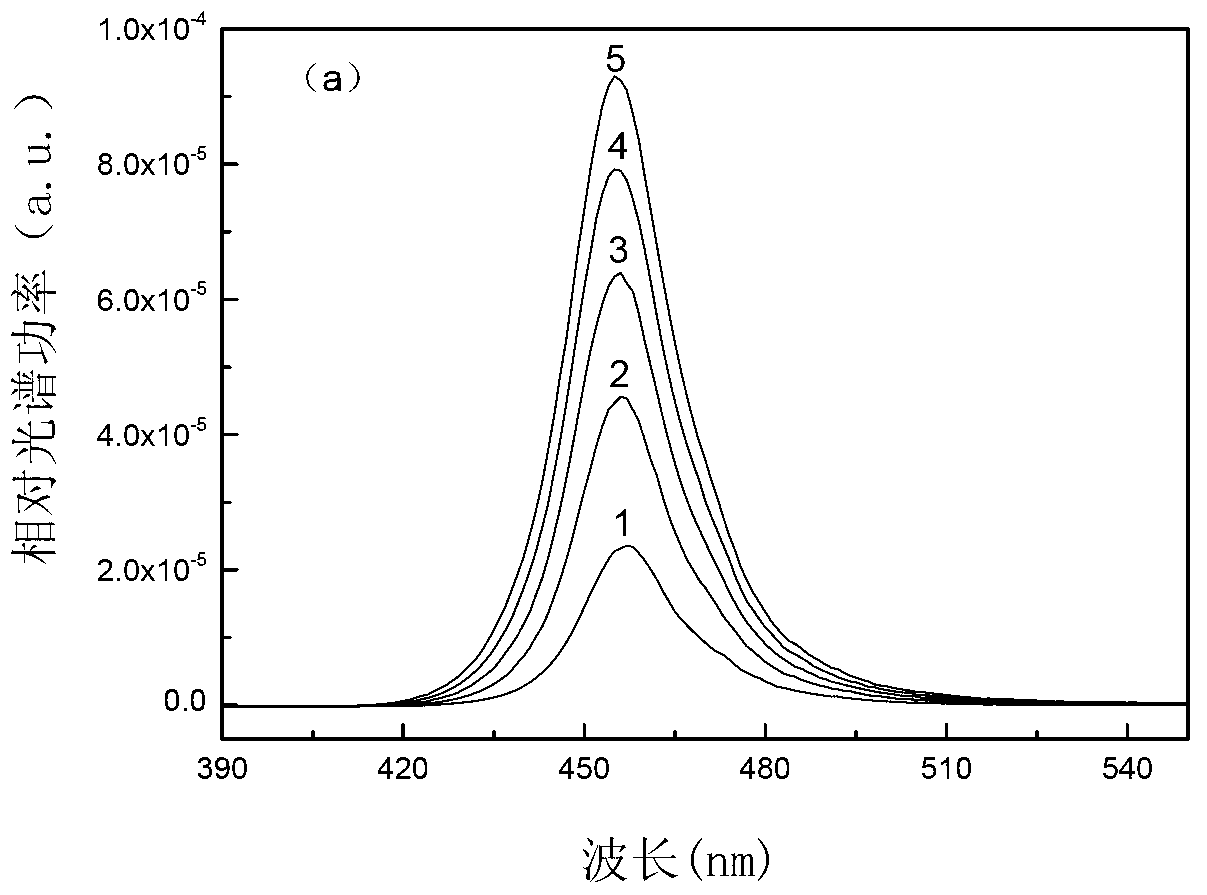

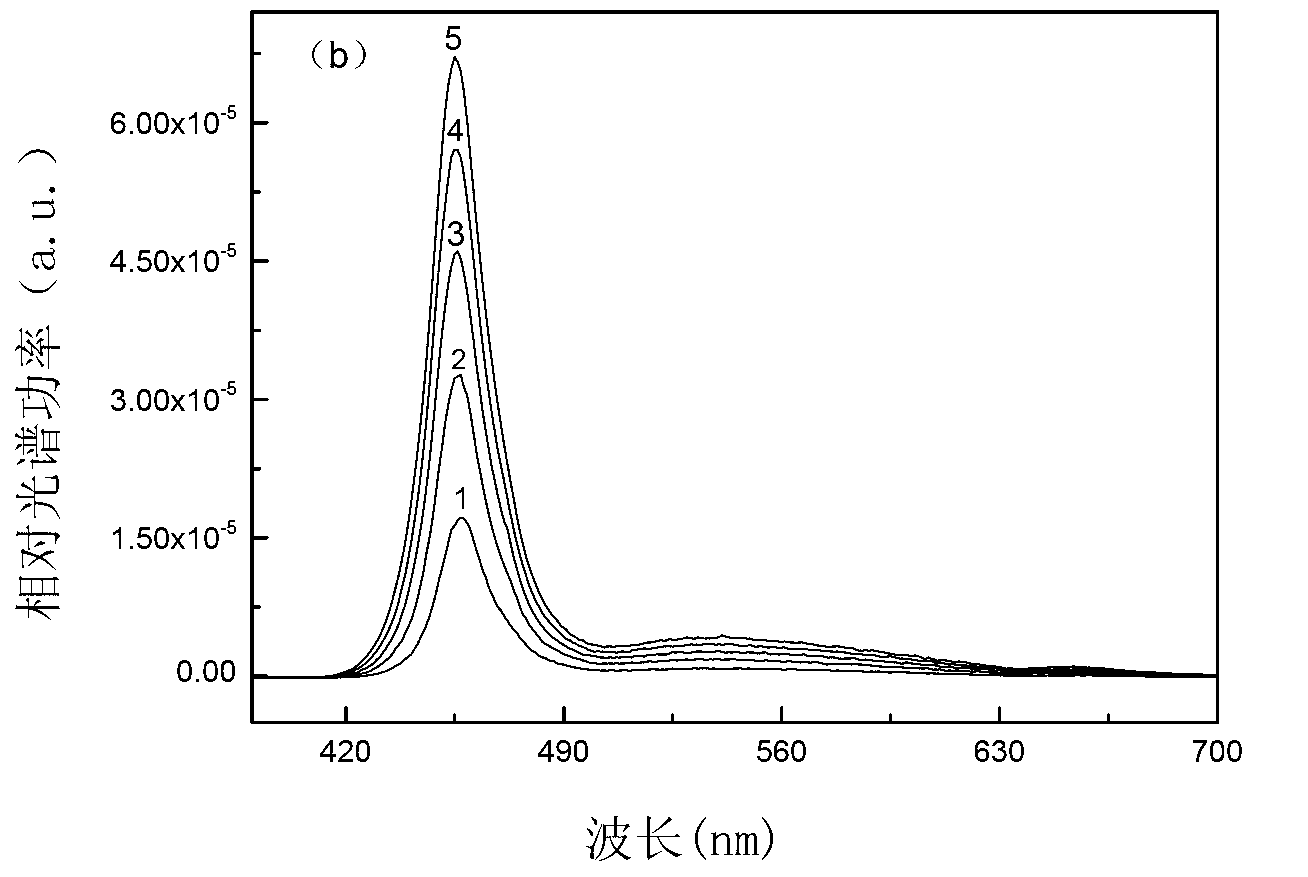

[0044] (1) Fix the standard whiteboard on the fixture, turn on the blue LED light source 4, set its working current to 100mA, 200mA, 300mA, 400mA, 500mA, and the spectral range to 380-780nm, and set the heat sink temperature to 25°C, The light emitted by the blue LED light source 4 is vertically incident on the position of the standard whiteboard through the light output tube 3 and is evenly scattered in the integrating sphere 2. After the light is absorbed by the cosine collector 7, it is analyzed and processed by the Spectro320 spectrometer 8, and the spectral power distribution of the excitation light source is obtained as follows: figure 2 and 3 shown.

[0045] (2) figure 1 The standard white board is replaced by the fluorescent powder to be tested, turn on the blue LED light source 4, set its working current to 100mA, 200mA and 300mA, 400mA, 500mA, set the heat sink temperature to 25°C, and the spectral range to 380-780nm. The light emitted by the light source 4 is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com