Switching pawl type uniform reciprocating mechanism

A technology of reciprocating mechanism and pawl, which is applied in the field of switching pawl type uniform reciprocating mechanism, can solve the problem that the mechanism is difficult to reach a stable state, and achieve the effects of constant mechanism load, small space, and high speed stabilization accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

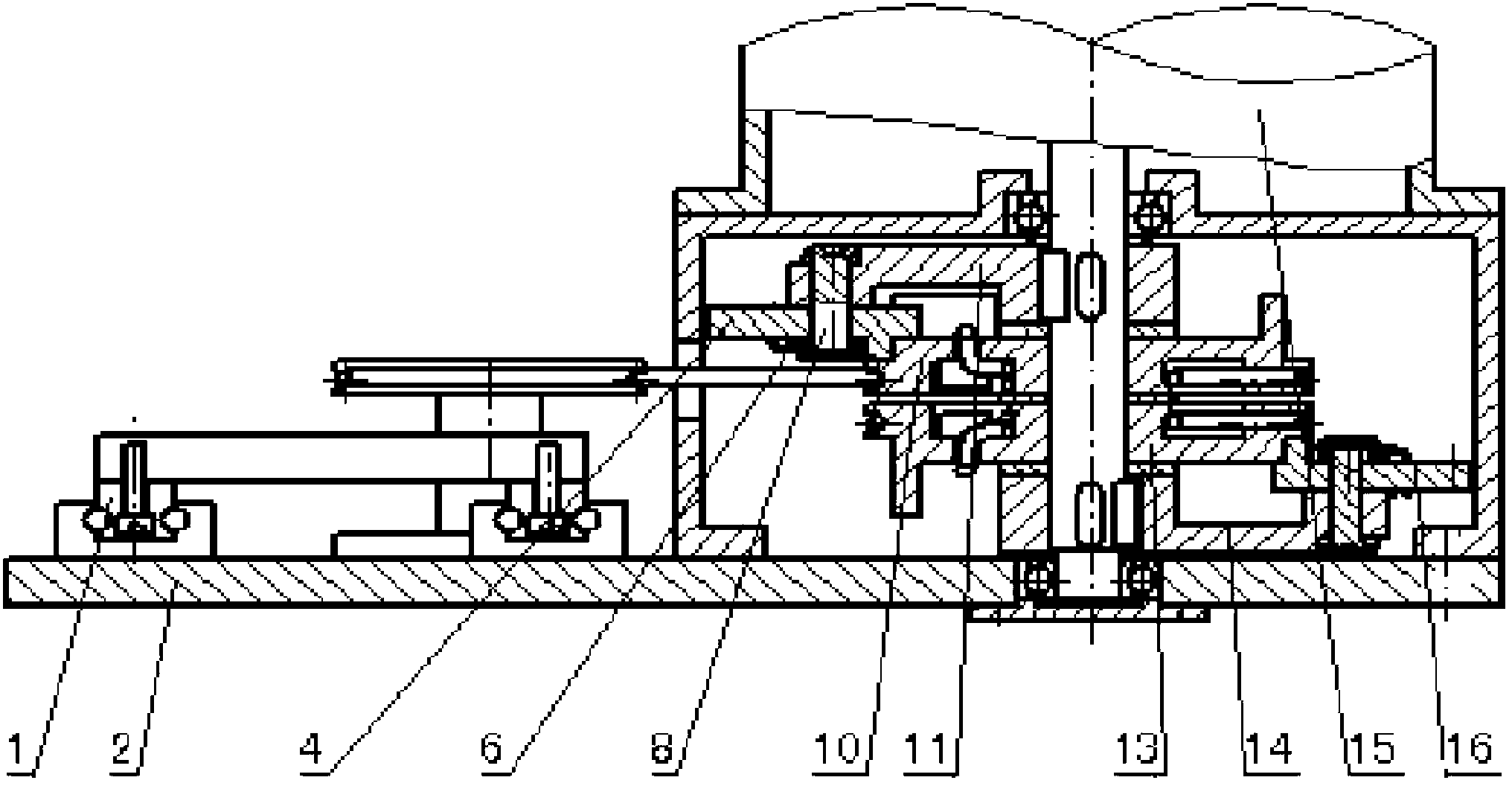

[0021] The inventive idea of the present invention is: the switching pawl type uniform speed reciprocating mechanism of the present invention, in order to make a reciprocating motion reach the state of uniform speed linear motion, the drive of the rotating motor is converted into a uniform speed linear motion by the mechanism, and then return motion is performed after it is in place. , is a differential constant mechanism that produces continuous uniform motion.

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

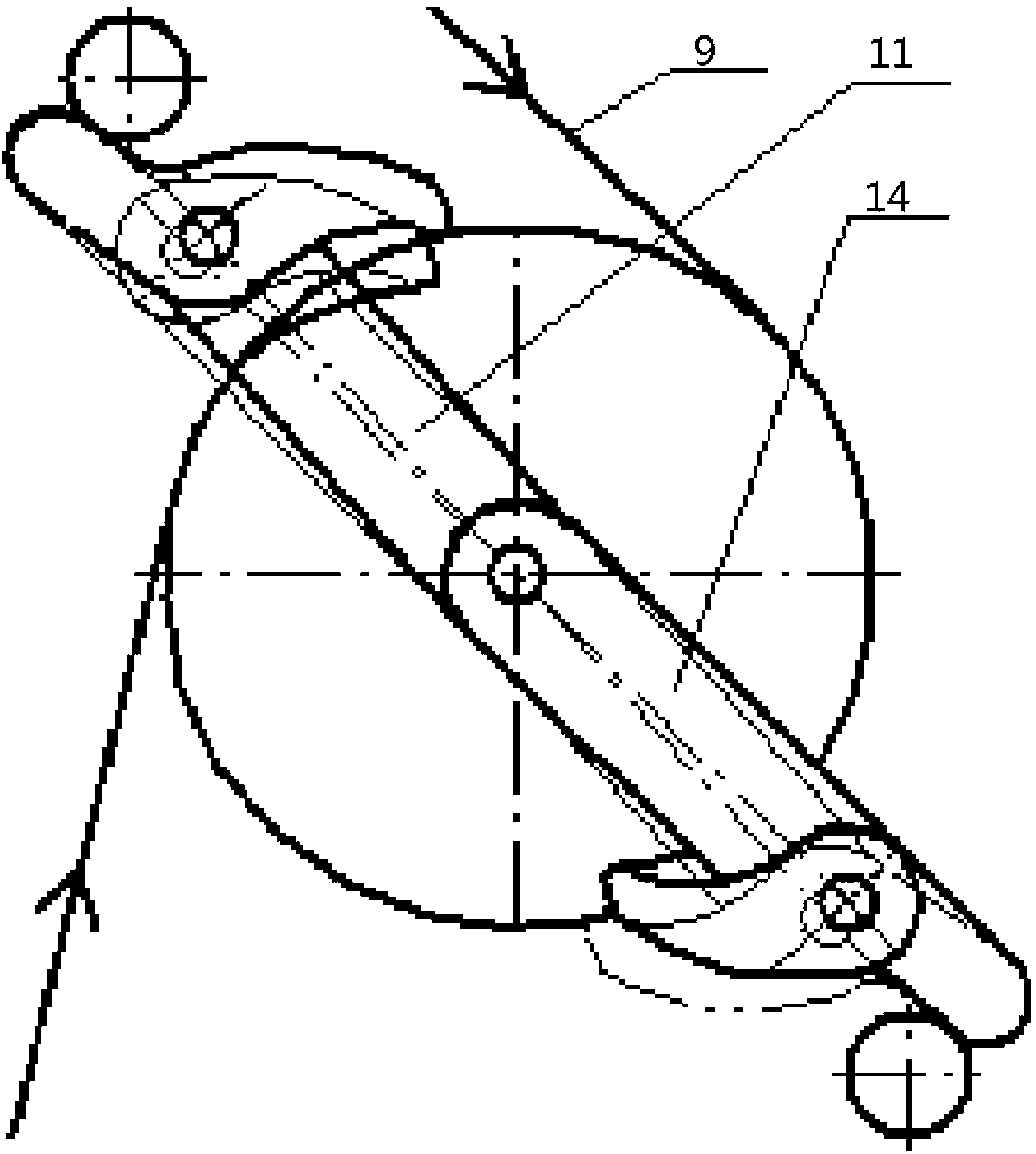

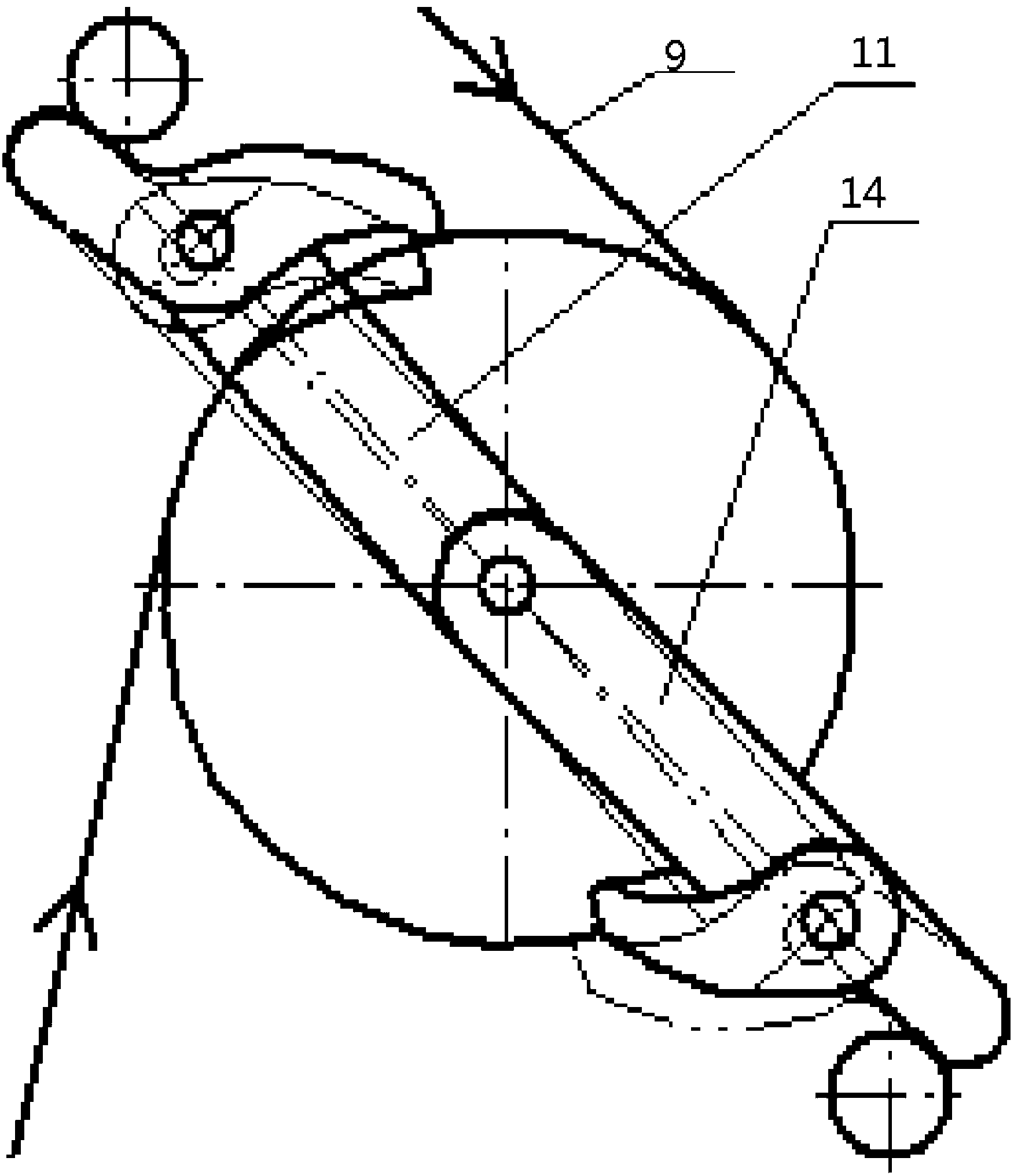

[0023] The switching pawl type uniform speed reciprocating mechanism of the present invention is mainly composed of a linear guide rail 1, a base plate 2, a buffer force accumulator 3, an upper pawl 4, a slit assembly 5, a return coil spring 6, a guide wheel 7, a turning shaft 8, and a steel cable 9. The upper wire wheel 10, the upper swing lever 11, the upper trigger block 12, the lower wire wheel 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com