Cold state simulation system applied to coal chemical industry

A cold state simulation, coal chemical technology, applied in the field of simulation, can solve the problems of inconvenient use of actual production equipment and safety, and achieve the effect of improving hands-on and thinking ability, strong practicality and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

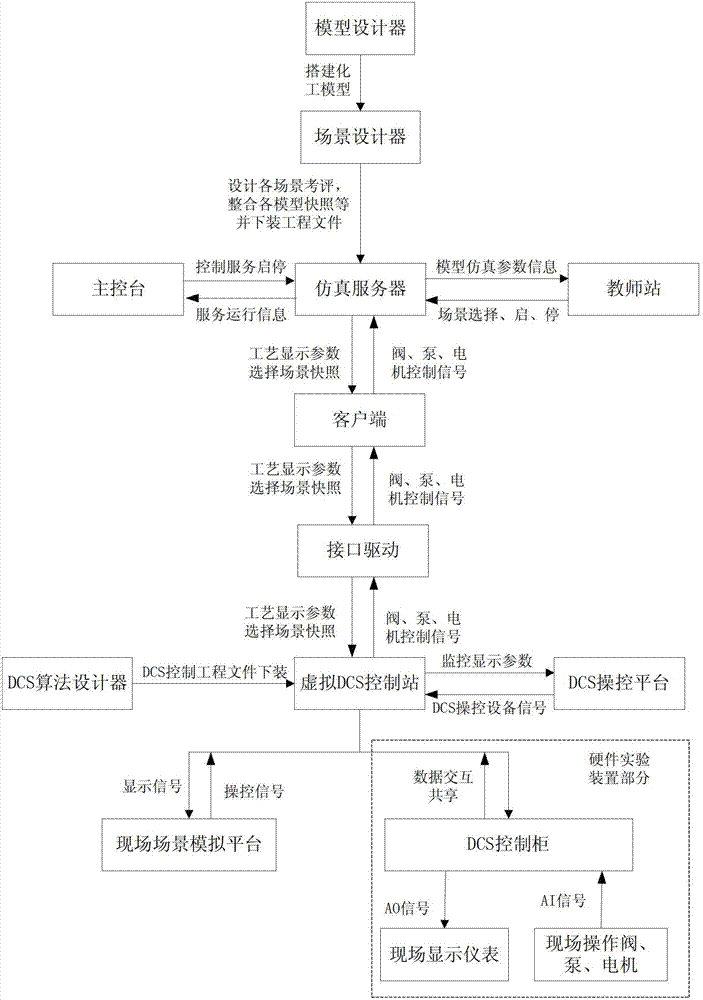

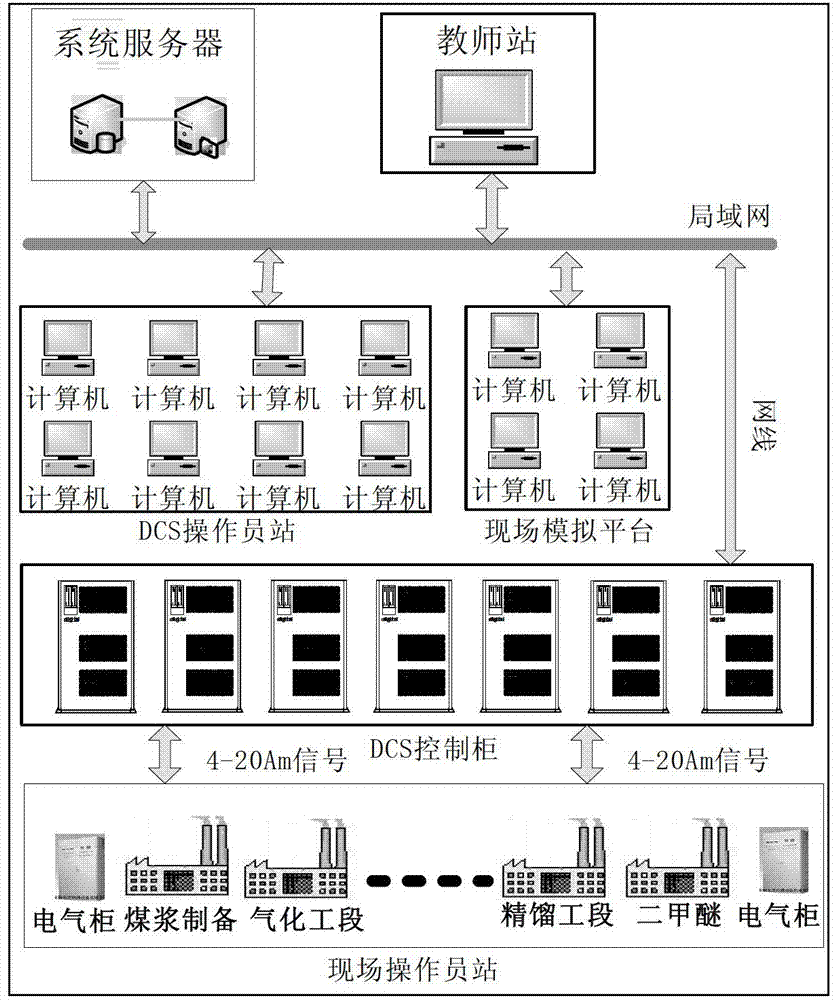

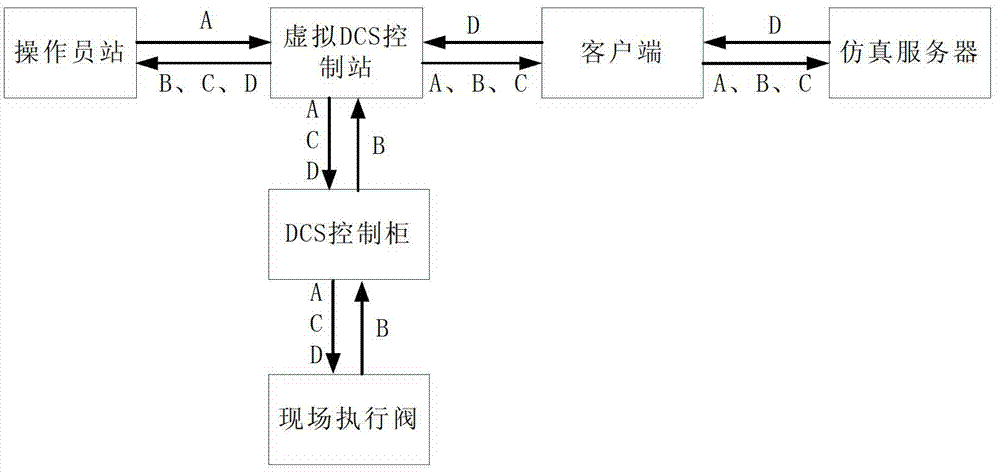

[0012] Example: such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a cold state simulation system applied to coal chemical industry, including three parts: software system, hardware device and network communication.

[0013] The specific realization process of a kind of cold state simulation system applied to coal chemical industry of the present invention is as follows:

[0014] (1) Build a simulation training software system for coal chemical industry by adopting distributed design method

[0015] a. Model Designer

[0016] The model designer is a key part of the whole simulation system, which determines the accuracy of chemical process simulation. The design of the model simulator is based on modularization. First, based on the basic physical and chemical conservation laws (momentum conservation, mass conservation and energy conservation, etc.), the heat exchangers, condensers, separation towers, washing towers, pumps, Regulatory valves, pumps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com