Method for preparing magnetism biomass adsorbent and removing heavy metal

A biomass adsorbent, biomass technology, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problem of less magnetic modification, achieve no secondary pollution, convenient and controllable separation, The effect of a simple synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After sieving the wood powder, wash it with deionized water to remove the dirt on the surface, and then dry it at 80°C for 12h. Weigh 10g of wood powder and add it to 500mL of 1% acetic acid solution and stir for 1h, then weigh 1g of chitosan powder and dissolve it in 500mL of 1% acetic acid solution and keep stirring for 1h. Then the above two solutions were mixed together and stirred rapidly for 30 minutes to form a stable suspension solution, and 1 g of the prepared magnetic Fe 3 o 4 The powder continued to stir for 3h. After the reaction, pour the above solution into 500mL 1mol / L NaOH solution, stir at 50°C for 5h, then use a magnet (3000-5000GS) to select the magnetic wood powder, and wash it with deionized water until neutral. Dry the obtained magnetic wood powder at 80°C for 24 hours for use.

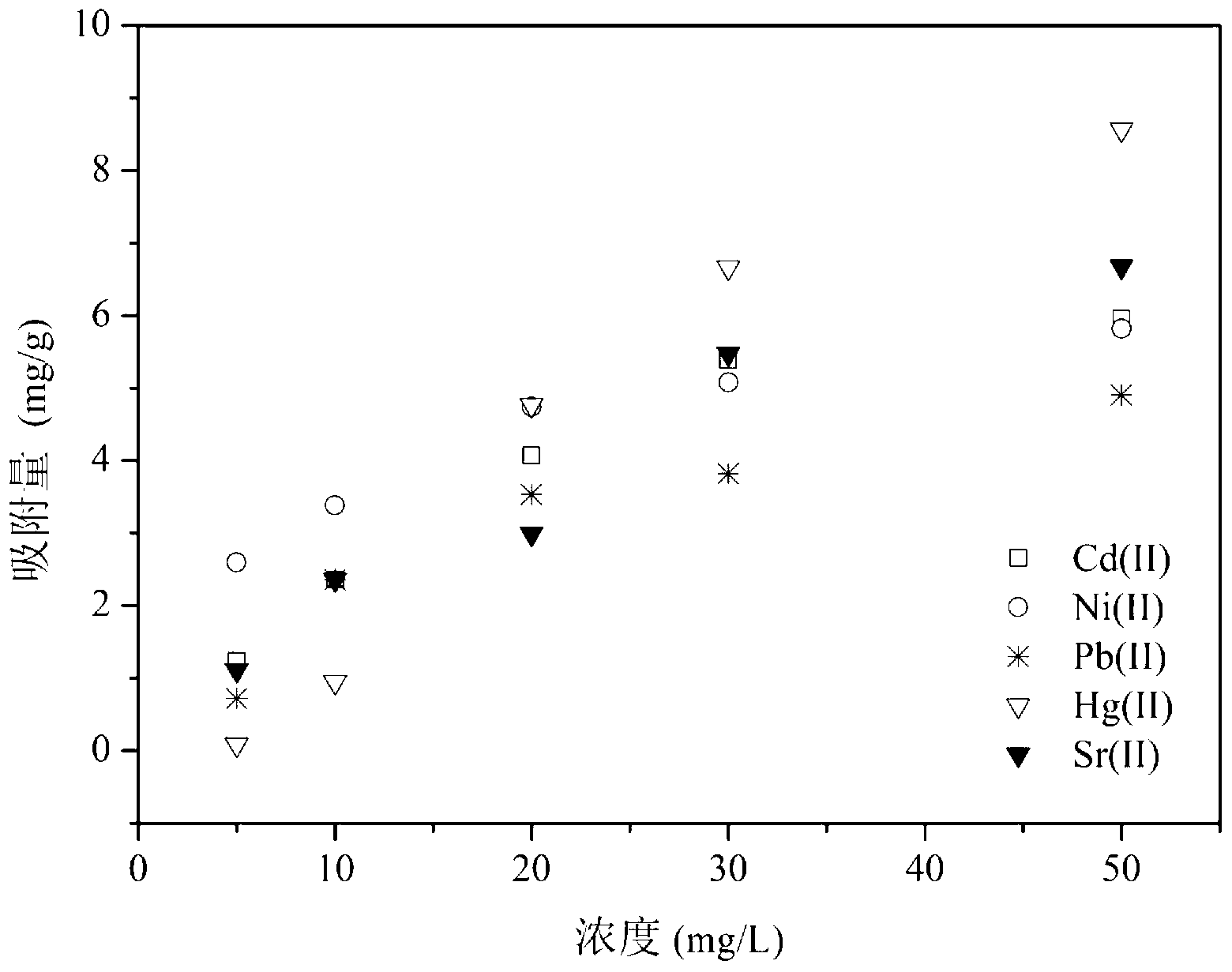

[0022] Weigh 0.1g of magnetic wood powder adsorbent and add it to 50mL solution containing heavy metals Ni(II), Hg(II), Sr(II), Cr(VI) at a concentration of 5-50mg / L, s...

Embodiment 2

[0024] After sieving the wood powder, wash it with deionized water to remove the dirt on the surface, and then dry it at 80°C for 12h. Weigh 10g of wood powder and add it to 500mL of 1% acetic acid solution and stir for 1h, then weigh 1g of chitosan powder and dissolve it in 500mL of 1% acetic acid solution and keep stirring for 1h. Then the above two solutions were mixed together and stirred rapidly for 30 minutes to form a stable suspension solution, and 1 g of the prepared magnetic Fe 3 o 4 The powder continued to stir for 3h. After the reaction, pour the above solution into 500mL 1mol / L NaOH solution, stir at 50°C for 5h, then use a magnet (3000-5000GS) to select the magnetic wood powder, and wash it with deionized water until neutral. Dry the obtained magnetic wood powder at 80°C for 24 hours for use.

[0025] Weigh 0.2g of magnetic wood powder adsorbent and add it to 50mL solution containing heavy metal As(V) with a concentration of 1000μg / L, shake for 3h, and analyze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com