Steel-aluminum rail welding line equipment

A welding production line, steel-aluminum composite technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high precision requirements for composite parts, complicated and huge equipment, and numerous processes, etc., to achieve the working principle Simple and easy to understand, uniform and beautiful weld seam, ensuring the effect of feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

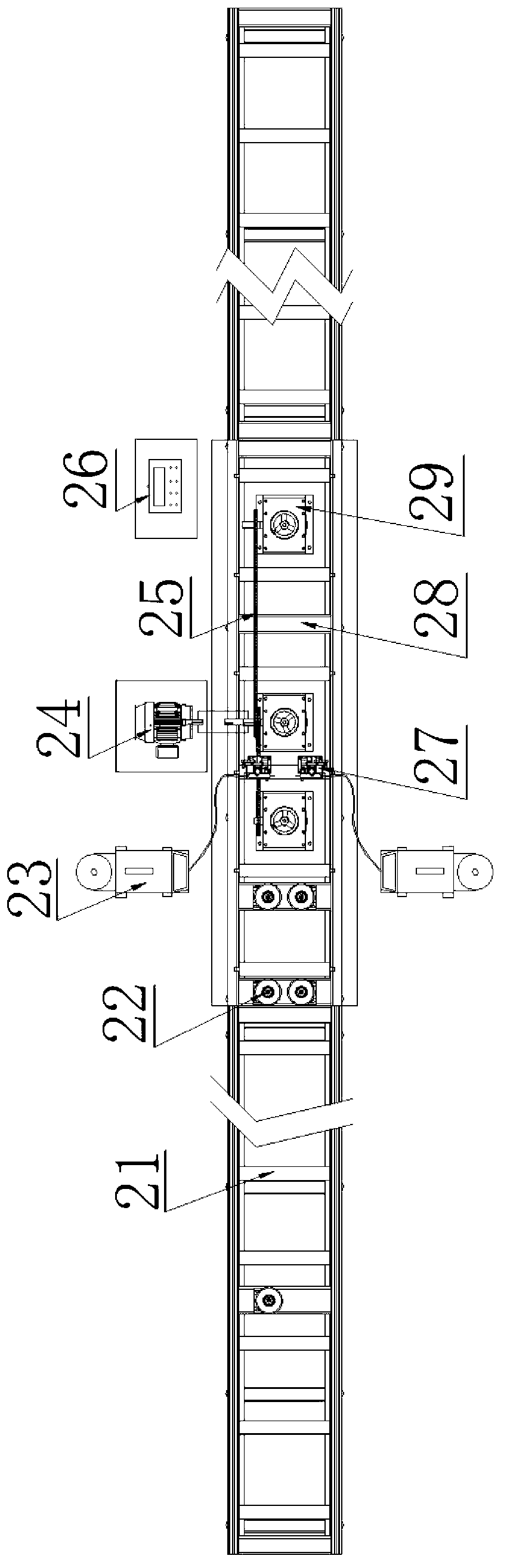

[0017] like Figure 1-5 As shown, the production line equipment of the present invention consists of 6 groups of roller conveyor frames 21, lateral positioning frame 22, welding unit 23, motor assembly 24, transmission chain 25, control console 26, 2 welding torch fixing frames 27, main workbench 28 and 3 groups of roller transmission groups 29 form.

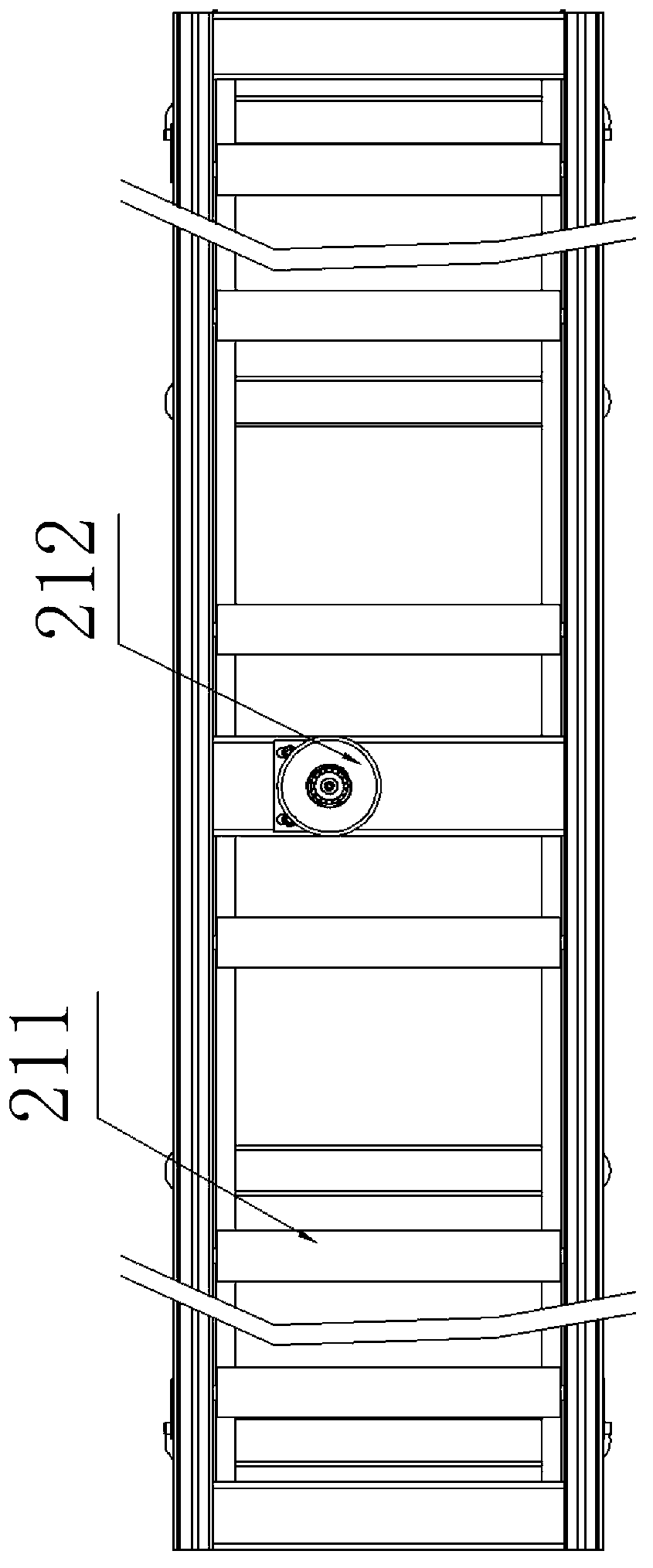

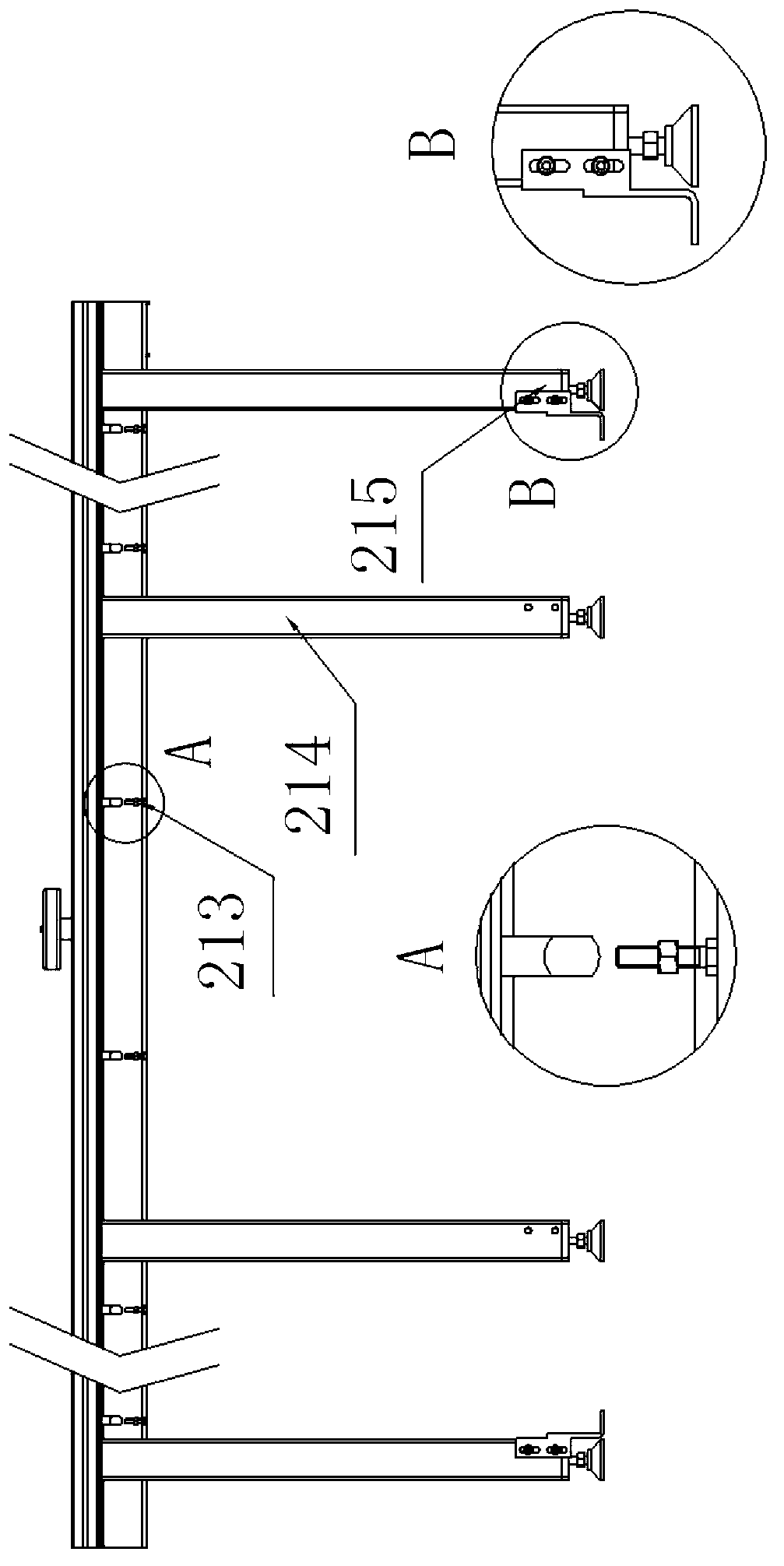

[0018] The main workbench 28 is a common operating platform, and three groups of roller conveyor frames 21 are respectively placed in the front and back. The roller conveyor frames 21 are composed of drive rollers 211, transverse guide wheels 212, adjustment screws 213, brackets 214, and adjustment legs 215. figure 2 , 3 As shown; the transmission rollers 211 are evenly arranged on the support 214, the transverse guide wheel 212 is fixed on the crossbeam in the middle of the support 214, the adjustment screw 213 is welded on both sides of the drive roller 211 below the axis, and the adjustment leg 215 is fixed on the support 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com