Nozzle transmission mechanism for 3D printer and 3D printer with same

A 3D printer and transmission mechanism technology, applied in the field of 3D printing, can solve the problems of low positioning accuracy, unfavorable cost control, and low printing efficiency, so as to improve efficiency, reduce printing cost, and reduce defective rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

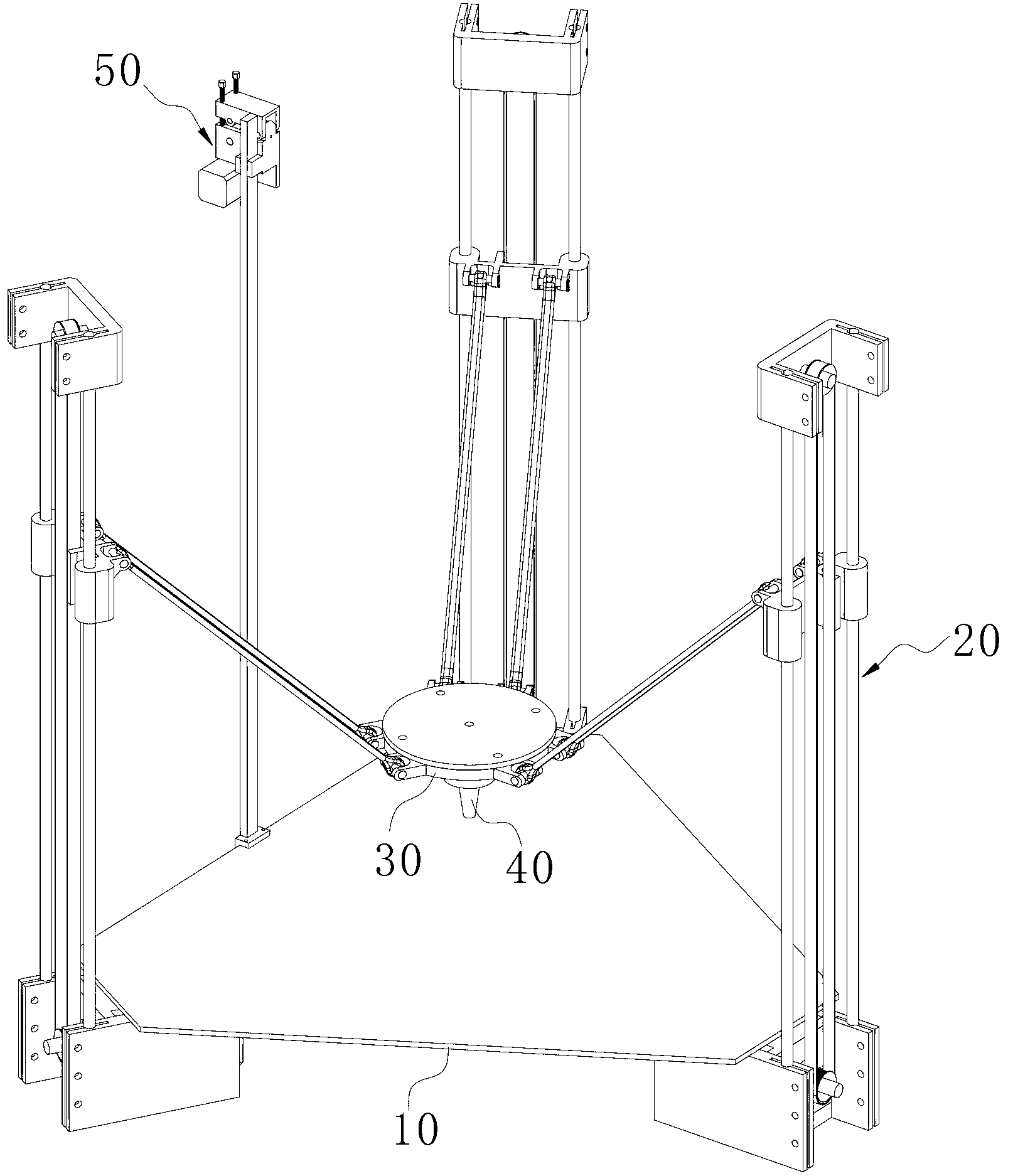

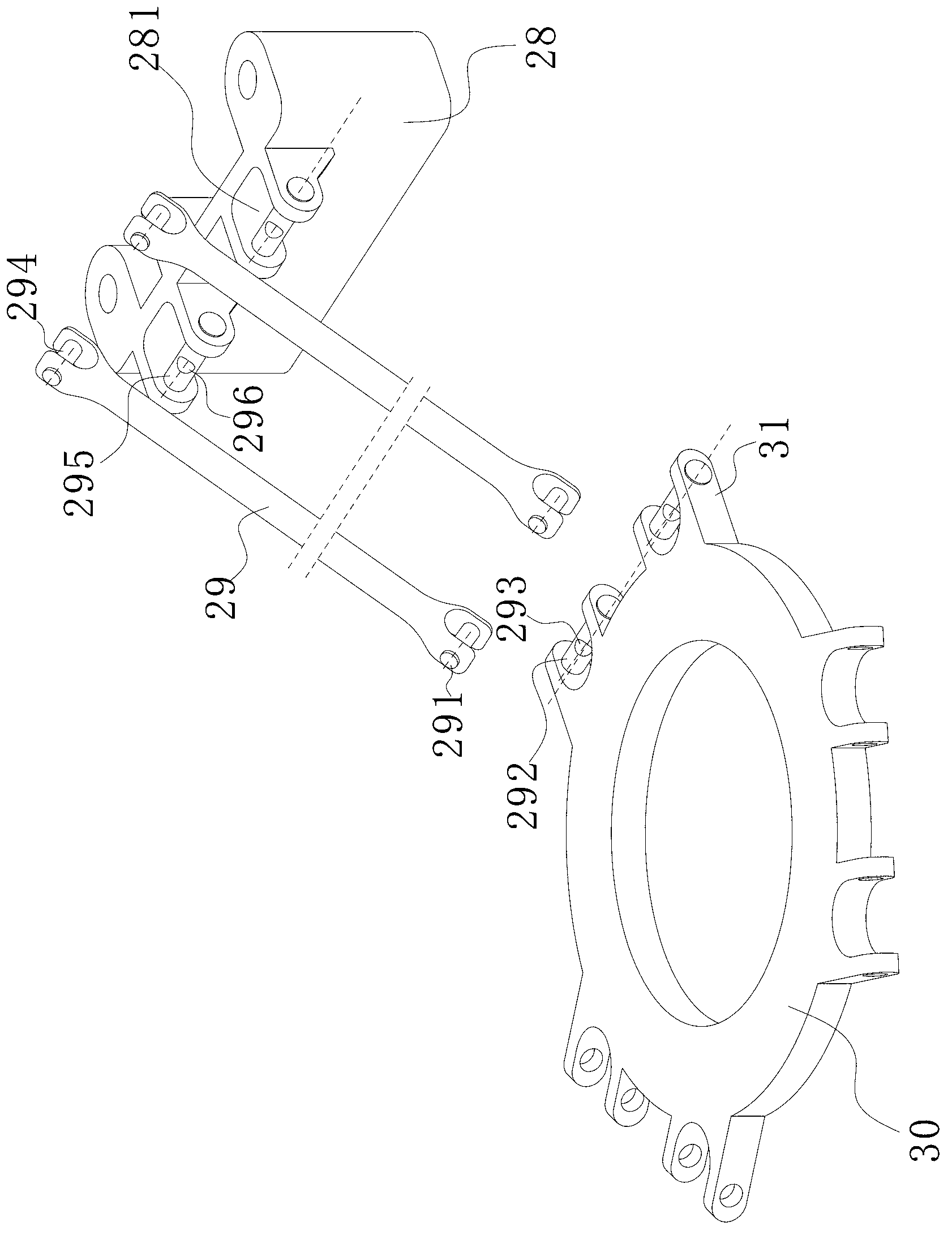

[0040] see figure 1 , 2 3. The nozzle transmission mechanism of the present invention includes a platform 10, a mounting base 30, three transmission components 20 and a controller (not shown in the figure). The platform 10 is mainly used to place the printing workpiece and serve as the installation basis of the entire transmission mechanism. The two transmission components 20 work together to drive the mounting seat 30 on which the spray head 40 is fixed to move in the height direction and the horizontal direction.

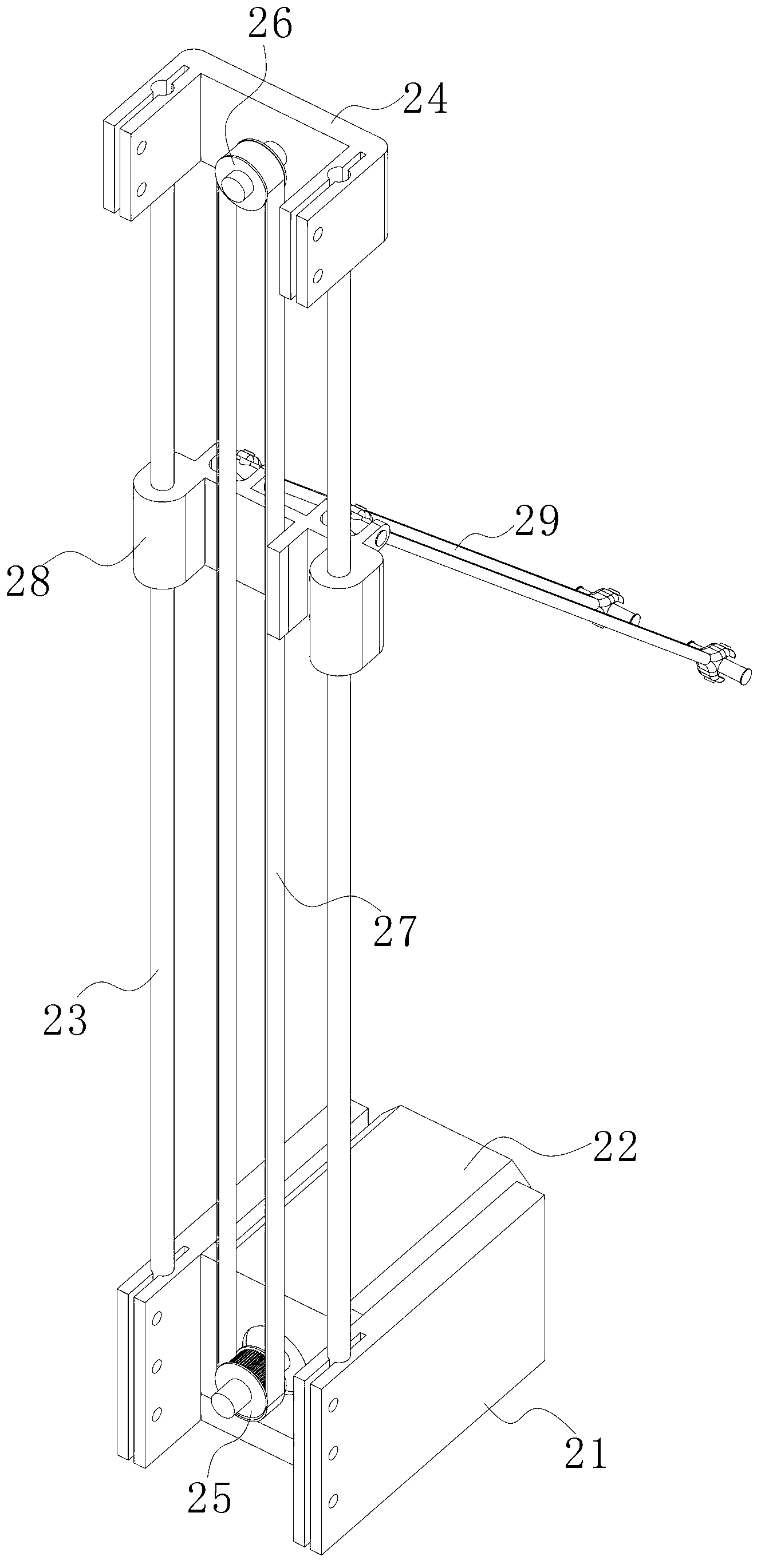

[0041] Three transmission assemblies 20 are evenly distributed on the periphery of the platform 10, and each transmission assembly 20 includes a motor base 21, a driving motor 22, two guide rods 23, a fixed seat 24, a driving pulley 25, a driven pulley 26, a synchronous Belt 27, sliding seat 28 and two connecting rods 29, wherein, motor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com