Piezoelectric-ceramics-based high-speed high-precision macro-micro platform and switching method

A piezoelectric ceramic and high-precision technology, which is applied in the field of high-speed and high-precision macro-micro platforms and switching based on piezoelectric ceramics, can solve the problems of limiting the accuracy, constraints and influence of high-speed motion platforms, and achieve simple and light mechanical structures, and platform The effect of small load and guaranteed motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

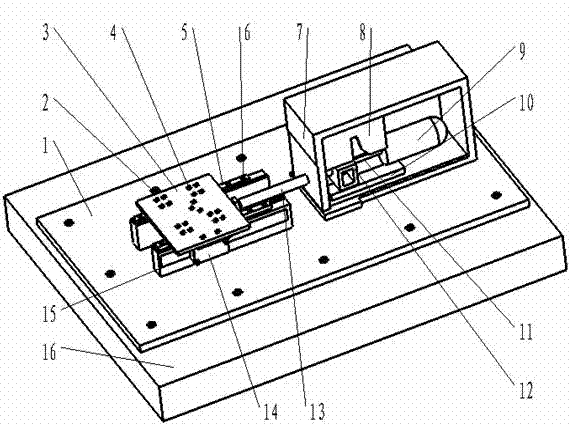

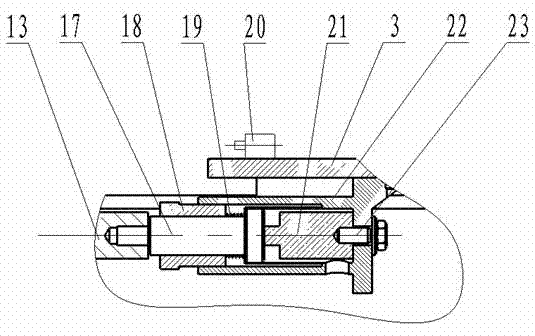

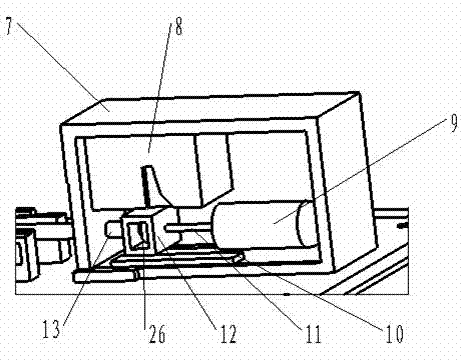

[0022] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the high-speed and high-precision macro-micro platform based on piezoelectric ceramics of the present invention includes a platform base plate 1 and a voice coil motor, the platform base plate 1 is installed on the vibration isolation base 16, and the voice coil motor is installed on the platform On one side of the bottom plate 1, the voice coil motor includes a voice coil motor housing 7, a voice coil motor magnet assembly 8, a voice coil motor coil 9, a voice coil motor linear encoder 10, a voice coil motor shaft 11, a motor shaft connecting frame 12, The voice coil motor extends shaft 13 and coupling 26, wherein the voice coil motor magnet assembly 8 is installed on the side of the voice coil motor housing 7, the voice coil motor coil 9 is installed on the bottom of the voice coil motor housing 7, and the voice coil motor shaft 11 Installed in the coil 9 of the voice coil motor, the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com