Method for removing impurity phosphorous in silicon

A technology of impurity and silicon melt, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of adding danger, affecting the research progress of impurity phosphorus, and industrial application, so as to achieve low production cost, improve technical level and Effects on product quality and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

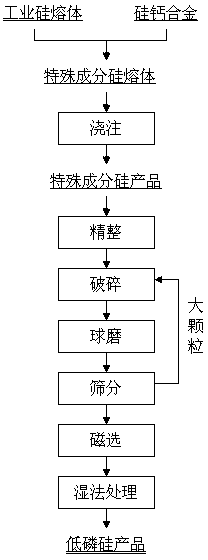

[0025] like figure 1 The process flow chart of the method for removing impurity phosphorus in silicon is as shown:

[0026] (1) Add 100kg at one time to 1000kg of industrial silicon melt (the content of impurity Fe is less than 0.2wt%, and the content of P is higher than 50ppmw) which is being refined outside the furnace and the temperature is higher than 1600°C. It meets the national standard YB / T5061-2007 Silicon-calcium alloy, obtain silicon melt with special composition, after 2 hours of refining outside the furnace, pour the silicon melt with special composition;

[0027] (2) Conduct controllable and segmented solidification of the silicon melt with special composition obtained in step (1): first condense the silicon melt with special composition at a condensation rate of 0.1°C / min, and then when the temperature drops to 1000°C, The condensation rate is condensed at 5°C / min, and finally when the temperature drops to 1000°C, the special composition silicon melt is natural...

Embodiment 2

[0031] like figure 1 The process flow chart of the method for removing impurity phosphorus in silicon is as shown:

[0032] (1) To the 1000kg industrial silicon melt (the content of impurity Fe is less than 0.2wt%, and the content of P is higher than 50ppmw) which is being refined outside the furnace and the temperature is higher than 1600℃, add 150kg in two times, which meets the national standard YB / T5061- The 2007 silicon-calcium alloy obtained a silicon melt with a special composition. After 4 hours of refining outside the furnace, the silicon melt with a special composition was poured;

[0033] (2) Controlled and segmented solidification of the silicon melt with special composition obtained in step (1): first condense the silicon melt with special composition at a condensation rate of 3°C / min, and then when the temperature drops to 1400°C, The condensation rate is condensed at 15°C / min, and finally when the temperature drops to 900°C, the special composition silicon melt...

Embodiment 3

[0037] like figure 1 The process flow chart of the method for removing impurity phosphorus in silicon is as shown:

[0038] (1) Add 180kg at one time to 1000kg of industrial silicon melt (the content of impurity Fe is less than 0.2wt%, and the content of P is higher than 50ppmw) which is being refined outside the furnace and the temperature is higher than 1600°C. It meets the national standard YB / T5061-2007 Silicon-calcium alloy, obtain silicon melt with special composition, after 3 hours of refining outside the furnace, pour the silicon melt with special composition;

[0039] (2) Controlled and segmented solidification of the silicon melt with special composition obtained in step (1): first condense the silicon melt with special composition at a condensation rate of 5°C / min, and then when the temperature drops to 1200°C , the condensation rate is condensed at 20°C / min, and finally when the temperature drops to 800°C, the special-component silicon melt is naturally cooled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com