Paeoniflorin molecularly imprinted polymer as well as preparation and application thereof

A technology of molecular imprinting and paeoniflorin, applied in ion exchange, other chemical processes, ion exchange regeneration, etc., can solve problems such as few literature studies, and achieve the effect of easy large-scale production and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Preparation of paeoniflorin molecularly imprinted polymer

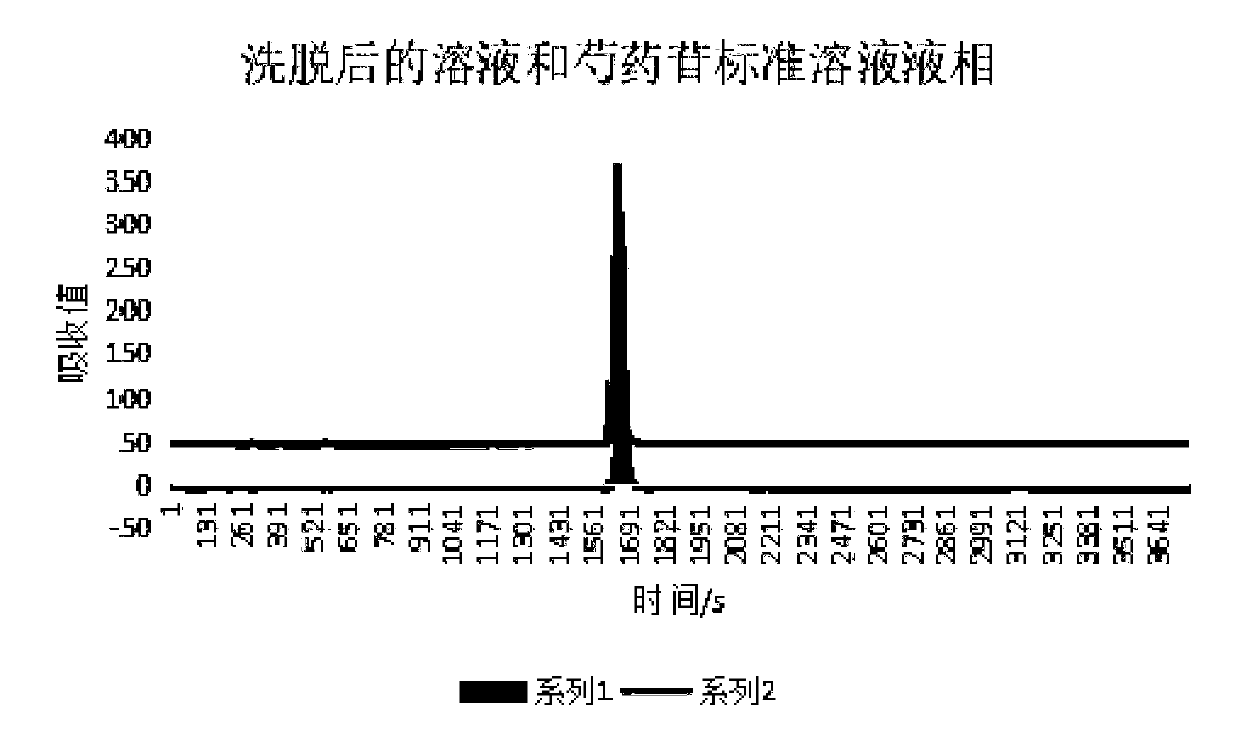

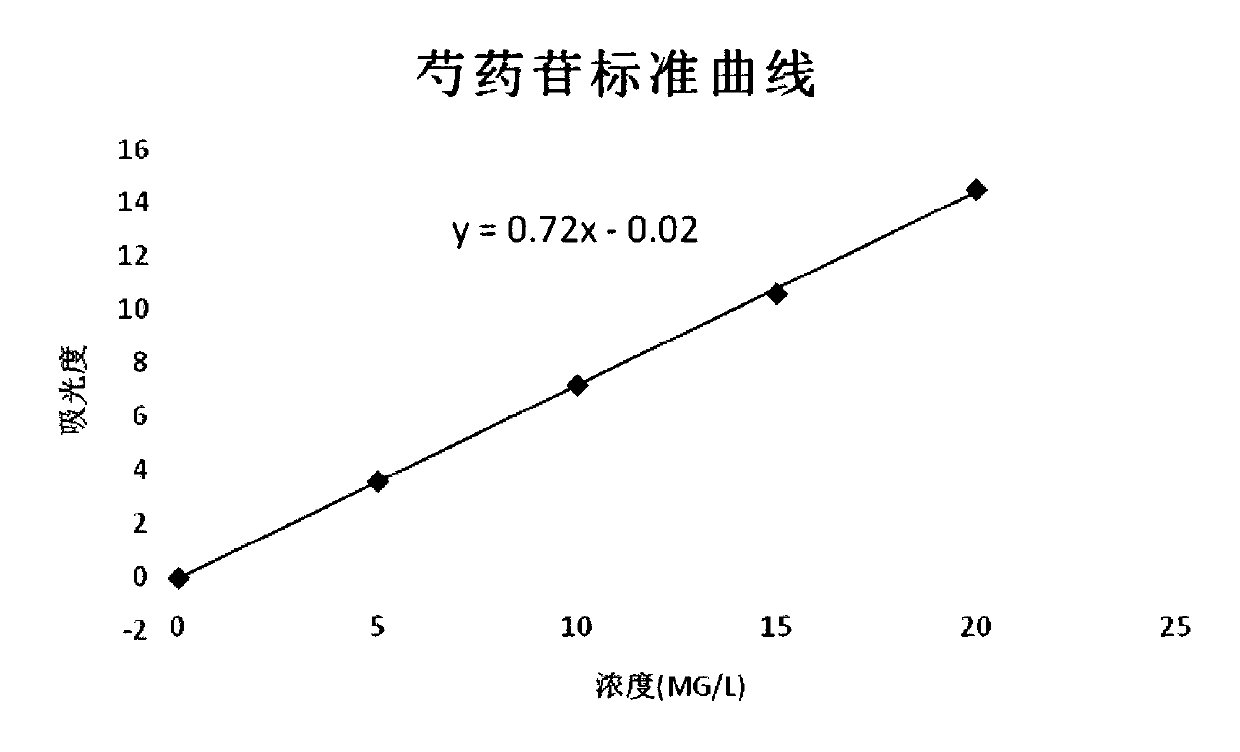

[0019] (1) Prepare paeoniflorin molecularly imprinted polymer by sol-gel method, the specific process is as follows: Weigh 200g of spherical silica gel with a particle size of about 50μm, disperse it in 10ml of absolute ethanol, and then add 3ml (1.56mmol) of cross-linking agent TEOS , functional monomer APTES (0.86mmol) and PTMOS (1.0mmol) each 200μL, after shaking at room temperature for 30min, add 0.1mol / L paeoniflorin (0.08mmol) ethanol solution 800μL, twice distilled water 1ml, 100μL concentrated HCl (concentration 36 %), reacted at room temperature for 4h, filtered to obtain 5.6g of filter cake. The filter cake was washed three times with absolute ethanol, dried at 60°C, and then the filter cake was eluted with methanol-acetic acid (9:1, v / v) to remove template molecules in the polymer until the washing liquid had no UV absorption at 230nm. The imprinted polymer was washed three times with methanol to...

Embodiment 2

[0025] 1. Preparation of paeoniflorin molecularly imprinted polymer

[0026] (1) The molecularly imprinted polymer of paeoniflorin was prepared by sol-gel method. The specific process is as follows: Weigh 200g of spherical silica gel with a particle size of about 50μm, disperse it in 10ml of absolute ethanol, and then add 6ml (3.12mmol) of cross-linking agent TEOS , functional monomer APTES1 (1.72mmol) and PTMOS (2.0mmol) each 400μL, shake at room temperature for 30min, add 0.1mol / L paeoniflorin (0.16mmol) ethanol solution 1.6mL, twice distilled water 1ml, 200μL concentrated HCl, room temperature The reaction was carried out for 4h to obtain 3.3g of the product. The product was first washed three times with absolute ethanol and dried. Then, the template molecules in the polymer were eluted with methanol-acetic acid (9:1v / v) until the washing solution had no UV absorption at 230nm, and the imprinted polymer was washed with methanol three times to remove residual acetic acid. ...

Embodiment 3

[0030] 1. Preparation of paeoniflorin molecularly imprinted polymer

[0031](1) The molecularly imprinted polymer of paeoniflorin was prepared by the sol-gel method. The specific process is as follows: Weigh 200 g of spherical silica gel with a particle size of about 50 μm, disperse it in 10 ml of absolute ethanol, and then add 1.5 ml of cross-linking agent TEOS (0.78 mmol), functional monomer APTES1 (0.43mmol) and PTMOS (0.5mmol) each 100μL, after shaking at room temperature for 30min, add 0.1mol / L paeoniflorin (0.04mmol) ethanol solution 400μL, twice distilled water 1ml, 50μL concentrated HCl, The reaction was carried out at room temperature for 4 hours to obtain 4.4 g of the product. The product was first washed three times with absolute ethanol and dried. Then use methanol-acetic acid (9:1v / v) to elute the template molecules in the polymer until the washing solution has no UV absorption at 230nm. The imprinted polymer was washed three times with methanol to remove residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com