Modular high-temperature gas filter

A high-temperature gas and filter technology, which is applied in the field of modular high-temperature gas filters, can solve the problems of increasing manufacturing, transportation costs and processing technology difficulties, unfavorable mass production and mass promotion, and complex multi-layer filter structures, and achieves the realization of The effect of space utilization and function, compact structure and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

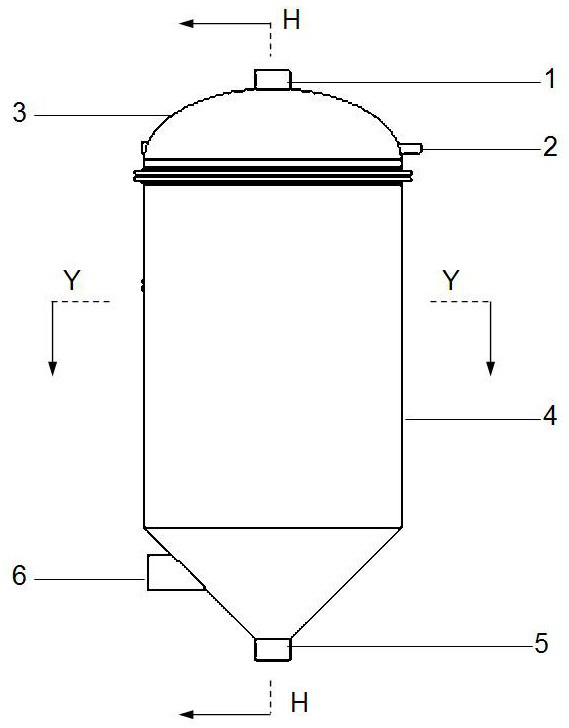

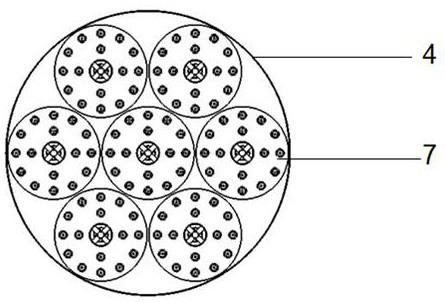

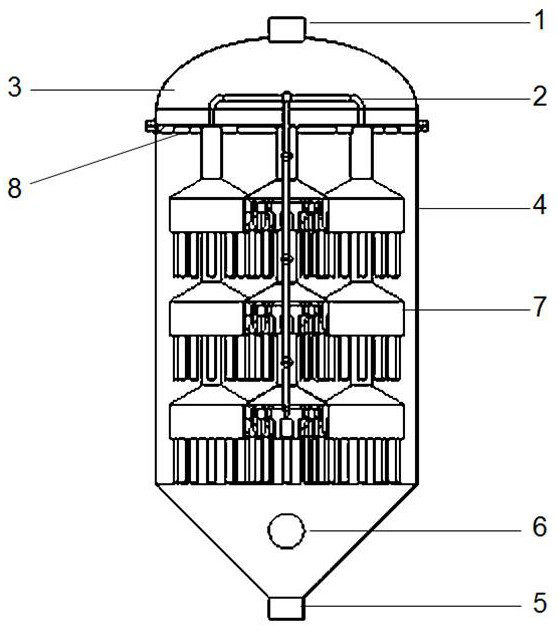

[0036] Such as Figure 1 to Figure 3As shown, the modular high-temperature gas filter includes a filter housing, several filter modules 7 sealed in the filter housing, a back-flushing cleaning system and a partition 8, wherein:

[0037] Such as figure 1 As shown, the filter housing is divided into an upper housing 3 and a lower housing 4, the upper housing 3 and the lower housing 4 are sealed and connected by flanges, an air outlet 1 is arranged directly above the top of the upper housing 3, and the lower housing 4 An air inlet 6 is arranged on the side of the bottom, and a slag discharge outlet 5 is arranged just below the bottom of the lower casing 4 .

[0038] Such as image 3 As shown, a partition 8 is arranged between the upper casing 3 and the lower casing 4 of the inner cavity of the filter housing, and the partition 8 is fixed between the flanges of the upper casing 3 and the lower casing 4 by bolts. Ventilation holes are provided on the top of the corresponding fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com