Preparation method of 7-bromine-1-chloronaphthalene

The technology of chloronaphthalene and dihydronaphthalene is applied in the field of preparation of 7-bromo-1-chloronaphthalene, can solve the problems of long steps and high risks, and achieves the effects of short steps, easy handling and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

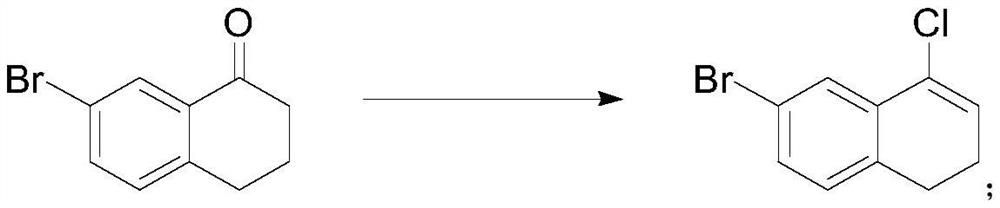

[0033] Chlorination reaction

[0034] In nitrogen atmosphere, 10mmol 7-bromo-3,4-dihydronaphthalene-1(2H)-one (2.25g), 20mmol triphenylphosphine PPh 3 (5.24g) was added to 200mmol CCl 4 (19.3 mL), stirred at room temperature for 30 min, and then heated to reflux to continue the reaction for 5 h. Cool down to room temperature after the reaction, add and CCl 4 An equal amount of n-hexane was diluted, and the precipitated crystals were collected by filtration and washed with n-hexane to obtain 6-bromo-4-chloro-1,2-dihydronaphthalene (yield 75%, 1.83 g, purity 95%).

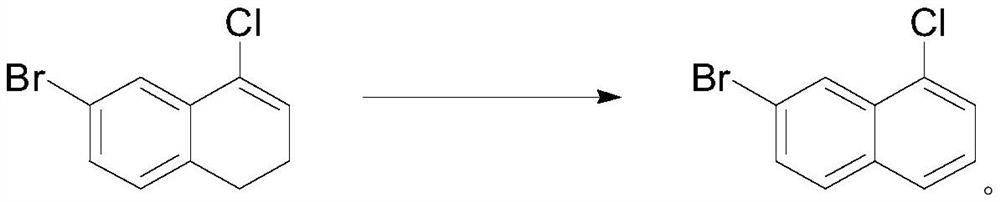

[0035] aromatization reaction

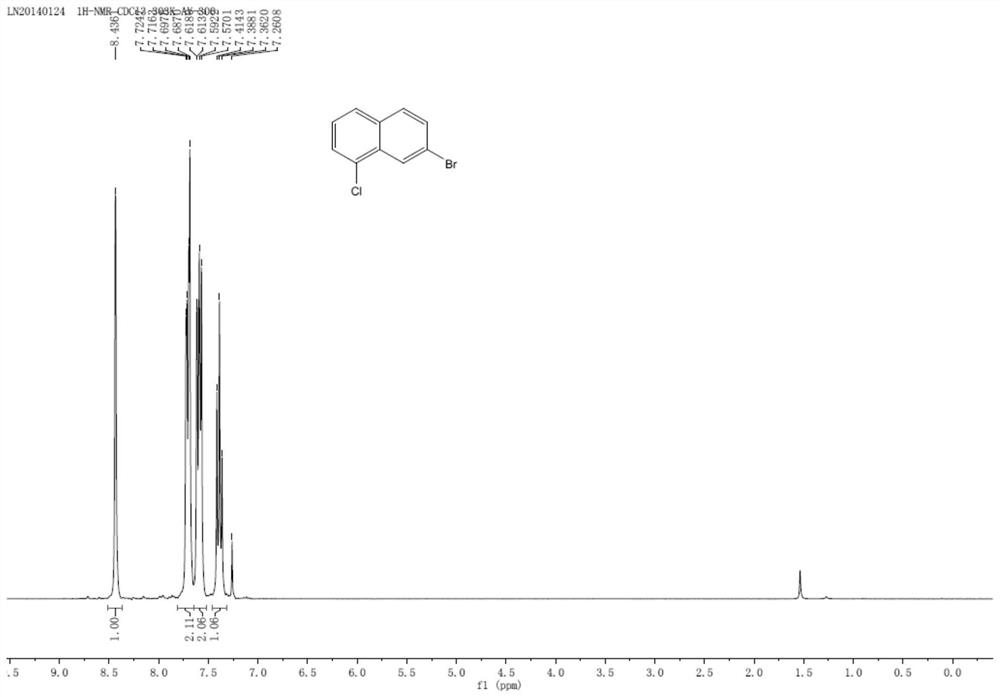

[0036] In a nitrogen atmosphere, 5mmol 6-bromo-4-chloro-1,2-dihydronaphthalene (1.22g), 15mmol DDQ (3.41g) were added to 100mmol toluene (10.6mL), and reacted at room temperature for 16h. After the reaction was finished, the solid was removed by filtration, and the solid obtained by rotary evaporation was recrystallized from petroleum ether to obtain the final product 7-bromo-1-chl...

Embodiment 2

[0038] Chlorination reaction

[0039] In a nitrogen atmosphere, 10mmol 7-bromo-3,4-dihydronaphthalene-1(2H)-one (2.25g), 20mmol triphenoxyphosphine (6.2g) were added to 200mmol CCl 4 (19.3 mL), stirred at room temperature for 30 min, and then heated to reflux to continue the reaction for 5 h. Cool down to room temperature after the reaction, add and CCl 4 Dilute with an equal amount of n-hexane, collect the precipitated crystals by filtration, and wash with n-hexane to obtain 6-bromo-4-chloro-1,2-dihydronaphthalene (yield 64%, 1.56 g, purity 90%).

[0040] aromatization reaction

[0041] In a nitrogen atmosphere, 5mmol 6-bromo-4-chloro-1,2-dihydronaphthalene (1.22g), 15mmol AIBN (2.46g) were added to 100mmol toluene (10.6mL), and reacted at room temperature for 16h. After the reaction was complete, the solid was removed by filtration. The solid obtained by rotary evaporation of the filtrate was recrystallized from petroleum ether to obtain the final product 7-bromo-1-chlor...

Embodiment 3

[0043] Chlorination reaction is with embodiment 1.

[0044] aromatization reaction

[0045] In a nitrogen atmosphere, 5 mmol 6-bromo-4-chloro-1,2-dihydronaphthalene (1.22 g), 15 mmol TEMPO (2.34 g) were added to 100 mmol toluene (10.6 mL), and reacted at room temperature for 16 h. After the reaction was complete, the solid was removed by filtration. The solid obtained by rotary evaporation of the filtrate was recrystallized from petroleum ether to obtain the final product 7-bromo-1-chloronaphthalene (yield 68%, 0.82 g, purity 89%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com