Large circulation garbage percolate treatment process with characteristic of adaptability

A technology of landfill leachate and treatment process, which is applied in the field of landfill leachate treatment technology, can solve the problems of foam environmental protection accident and cost increase, and achieve the effect of reducing volume, reducing structure size and saving infrastructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

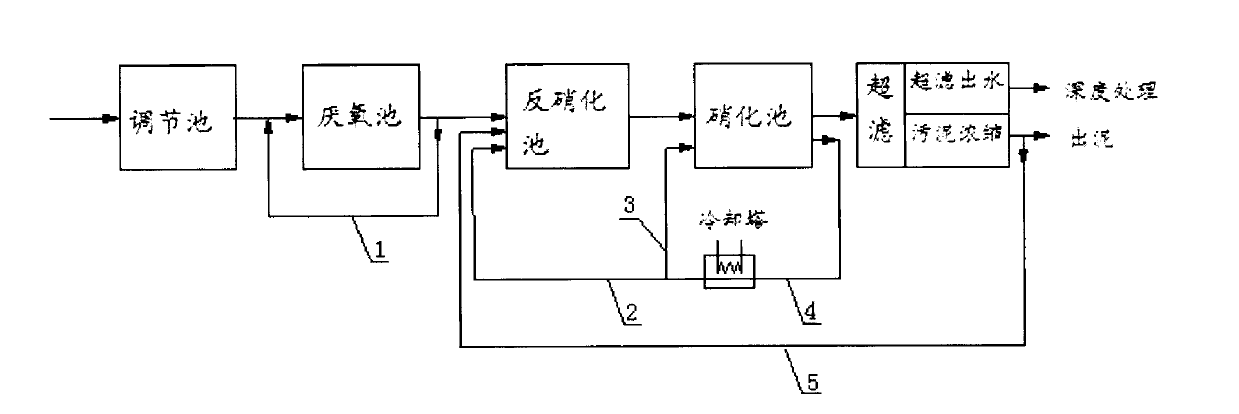

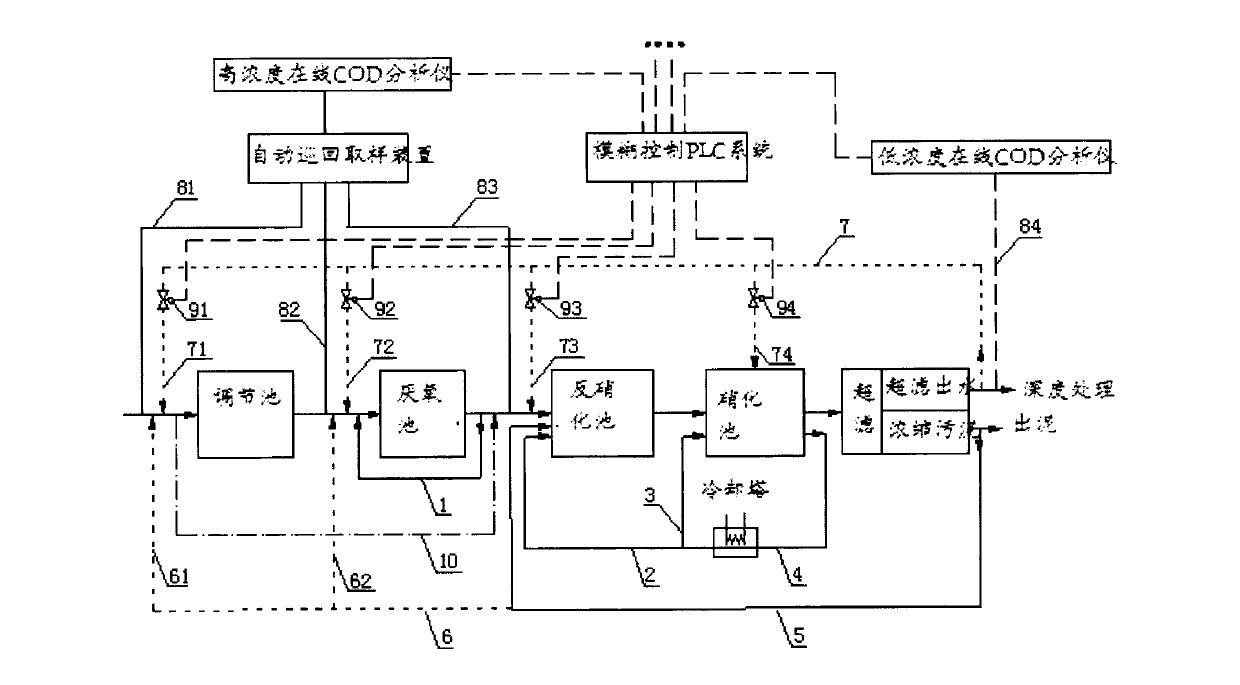

[0032] The invention relates to a large cycle adaptive landfill leachate treatment process, as attached figure 2 As shown, it includes the following four parts: (1) Ultrafiltration effluent return system, (2) Ultrafiltration concentrated sludge return system, (3) Beyond pipeline system, (4) Fuzzy control system. Among them, (1) the ultrafiltration effluent return system includes: the ultrafiltration effluent return pipeline 7, the ultrafiltration effluent returns to the regulating tank pipeline 71, the ultrafiltration effluent returns to the anaerobic tank pipeline 72, and the ultrafiltration effluent returns to the denitrification Pool pipeline 73, the ultrafiltration effluent returns to the nitrification tank pipeline 74; (2) the ultrafiltration concentrated sludge return system includes: ultrafiltration concentrated sludge return pipeline 5, ultrafiltration concentrated sludge return system improved pipeline 6, The ultrafiltration concentrated sludge returns to the regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com