Automatic tensioning machine

A tensioning machine and tensioning technology, used in ceramic molding machines, manufacturing tools, construction, etc., can solve problems such as error-prone, inability to guarantee the accuracy of prestressed tensioning values, and no way to adjust the flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

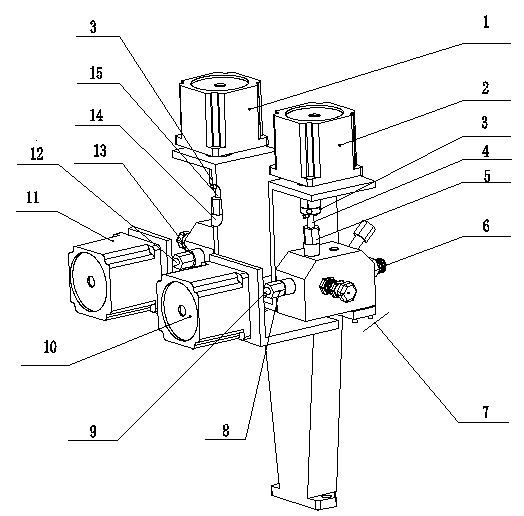

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

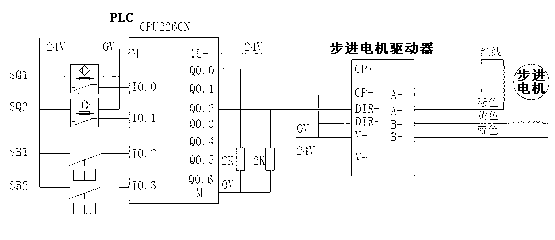

[0017] The automatic tensioning machine of the present invention comprises a high-pressure plunger hydraulic pump 6, a hydraulic jack, a high-pressure connecting oil pipe, a pressure sensor, a programmable logic controller PLC, a stepper motor driver and a stepper motor, wherein: the high-pressure plunger hydraulic pump, Hydraulic jack, high-pressure connecting oil pipe and pressure sensor are still connected in the traditional way, and high-pressure plunger hydraulic pump 6 links to each other with the oil cylinder of hydraulic jack by high-pressure connecting oil pipe, and pressure sensor is connected in the closed high-pressure oil circuit.

[0018] The present invention realizes the automatic tensioning process of the automatic tensioning machine by adding a stepping motor to the high-pressure plunger hydraulic pump 6 (model ZB4-500), and cooperating with a programmable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com